Snowmobile Arctic Cat (2008 year). Manual - part 37

2-85

2

NOTE: On the 500 cc after tightening the crank-

case, turn the engine right side up and tighten the

four MAG-housing cap screws in a crisscross pat-

tern to 16 ft-lb.

738-202A

NOTE: On the 500 cc, secure the connecting rods

with rubber bands. On the 600 cc, secure the con-

necting rods with rubber hoses.

15. Install the oil-injection pump retainer O-ring and

retainer.

FC082

NOTE: For assembling purposes, always use

new O-rings lubricated with oil on the oil injection

pump and retainer.

16. Install the O-ring and the oil-injection pump mak-

ing sure the pump shaft slot and pump driven gear

shaft align. Secure with two screws (coated with

blue Loctite #243). Tighten the two screws to 8 ft-

lb.

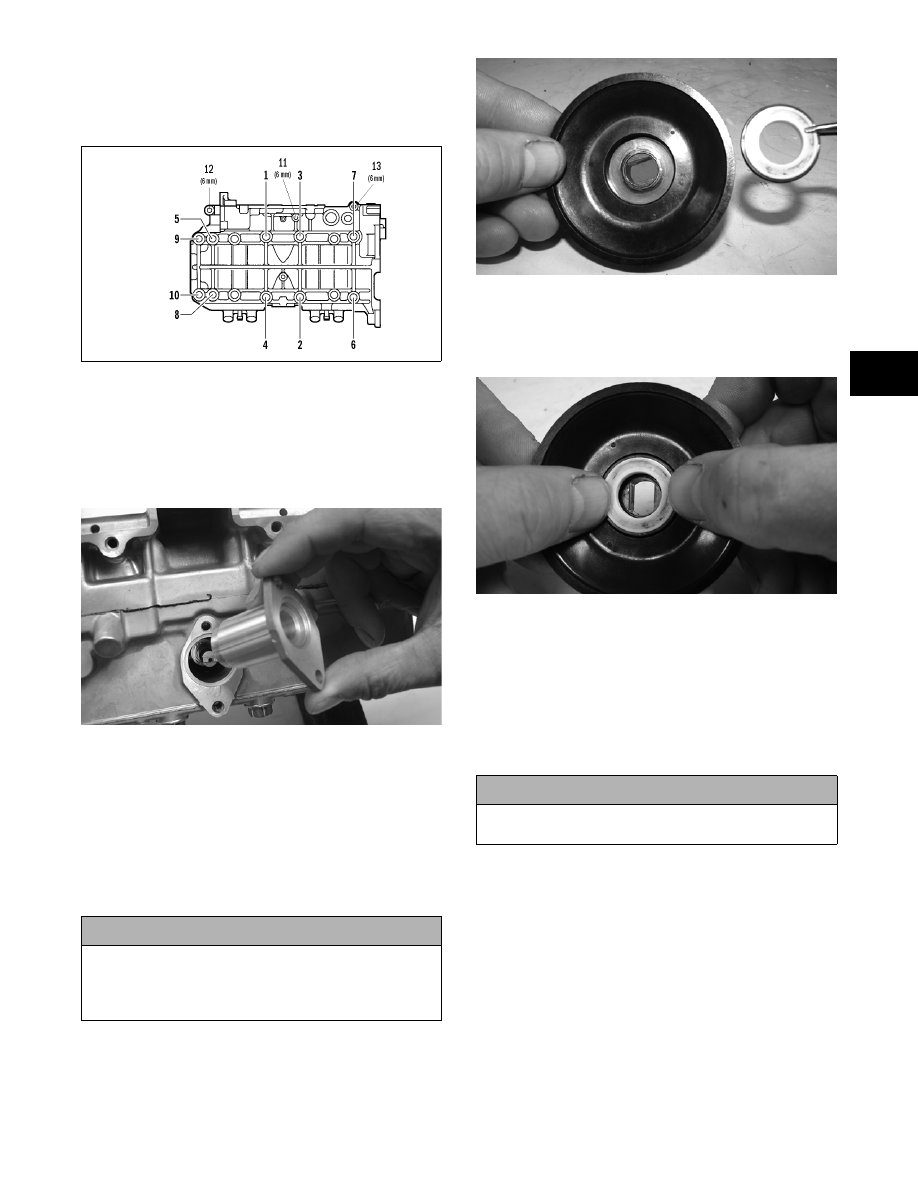

17. Position the ceramic/rubber seal into the back side

of the water pump impeller with the ceramic face

of the seal directed out.

CM168

18. Using both thumbs, press the seal into position

making sure its marked side is positioned towards

the rubber seal cup; then apply a thin coat of

grease to the seal outer surface.

CM169

19. Place the impeller into position and secure with a

cap screw and washer. Be sure the rubber side of

the washer is directed toward the impeller. Apply

blue Loctite #243 to the threads of the cap screw

and tighten to 8 ft-lb.

NOTE: For assembling purposes, it is advisable

to lubricate the rubber side of the washer before

installing.

20. Apply high-temperature sealant to the crankcase/

water pump cover seam; then install the dowel

pins into the crankcase.

! CAUTION

Be sure the oil-injection pump/water pump drive-

shaft is properly aligned with the slot of the oil-injec-

tion pump. The pump will be damaged if these two

components are not aligned.

600 cc

! CAUTION

If the rubber side of the washer is not positioned

toward the impeller, a coolant leak will result.