Snowmobile Arctic Cat (2008 year). Manual - part 34

2-73

2

AN327D

Servicing Top-Side

Components

Many services can be performed without removing the

engine. Some components may vary from model to

model. The technician should use discretion and sound

judgment when removing and installing components.

NOTE: Some photographs used in this sub-sec-

tion are used for clarity purposes only and are not

designed to depict actual conditions.

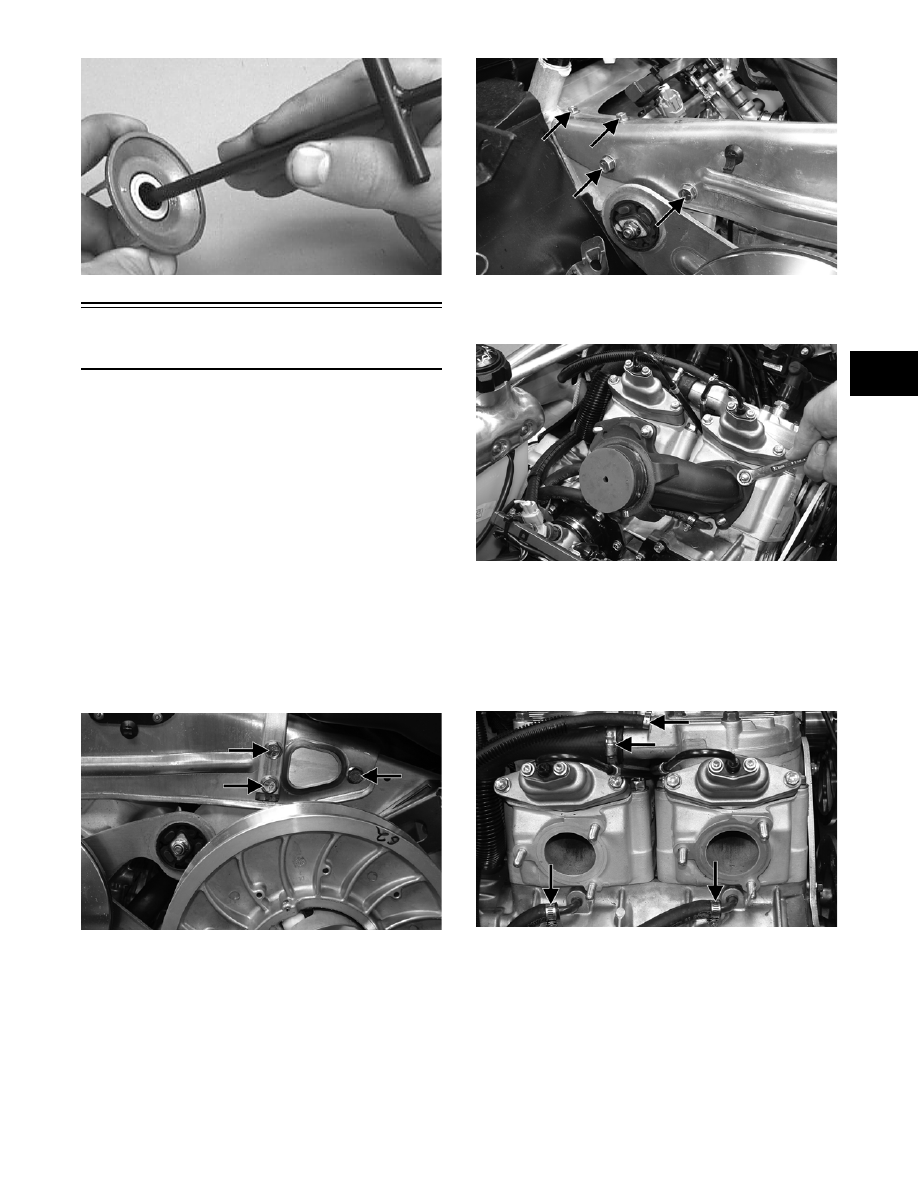

REMOVING TOP-SIDE

COMPONENTS

To access top-side components, use the following pro-

cedure:

1. Remove the cap screws securing the left-side

steering support and the side-plate brace to the

chassis; then remove the brace.

CM211A

CM212A

2. Remove the expansion chamber and resonator;

then remove the exhaust manifold.

CM213

3. Drain the engine coolant (see Liquid Cooling Sys-

tem - Section 3).

4. Remove the coolant hose and breather hose con-

nected to the cylinder head; then disconnect the

two coolant hoses located beneath the exhaust

ports on the cylinders.

CM214A

5. On the 600 cc, disconnect the APV cables from

the servomotor; then remove the APV’s from the

cylinder.