Snowmobile Arctic Cat (2008 year). Manual - part 14

1-51

1

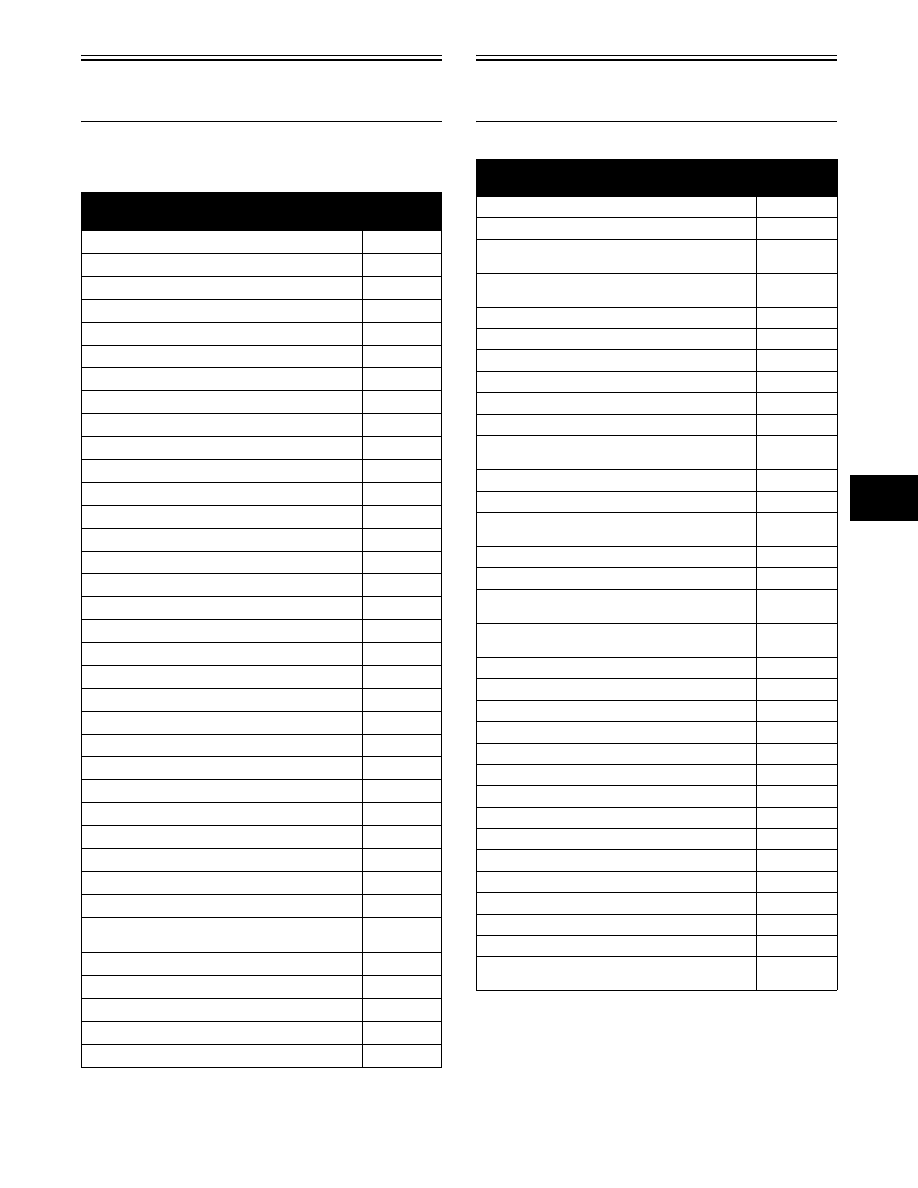

Drive System Torque

Specifications

NOTE: STD refers to chain case drive models;

ACT refers to gear case drive models.

* w/Blue Loctite #243

** w/Green Loctite #609

***w/Green Loctite #620

Rear Suspension

Torque Specifications

* w/Blue Loctite #243

ITEM

TORQUE

ft-lb

Drive Clutch

55

Spider***

250

Spider Retainer Nut***

85

Drive Clutch Cover

10

Cam Arm Pin Lock Nut

11

Cam Arm Set Screw***

19 in.-lb

Drive Clutch/Ring Gear***

22

Driven Pulley* (STD)

24

Driven Pulley (ACT)

32

Driven Pulley Roller Plate (STD)

20

Torque Bracket (STD)

5.5

Chain Case Top Sprocket**

40

Chain Case Bottom Sprocket**

35

Reverse Gear* (STD)

15

Chain Tensioner Arm* (STD)

8

Chain Case/Tunnel

15

Chain Case Cover

13

Chain Case Drain Plug

25

Shift Linkage Arm (STD)

25

Brake Caliper/Chain Case*

30

Brake Caliper/Chain Case (Panther 370)*

30

Brakeline/Fitting/Caliper (ACT)

10.5

Brakeline/Master Cylinder (ACT)

21

Flange Plate - STD (Lower)

15

Flange Plate - STD (Upper)

11

Torque Bracket Cover (ACT)

6

Movable Sheave (ACT)

6

Speedometer Sensor Bracket (ACT)

16.5

Gear Case/Chassis

20

Brake Caliper Housing/Chassis (ACT)

20

Outside Caliper Housing/Inside Caliper Housing

(ACT)

17

Gear Case Cover

12.5

Gear Case Drain Plug

12

Driveshaft/Output Shaft Cap Screw

70

Driveshaft/Brake Disc Retaining Nut (ACT)

120

Shift Actuator (ACT)

41 in.-lb

ITEM

TORQUE

ft-lb

End Cap

6.5

Wear Strip/Rail

50 in.-lb

Idler Wheel/Mounting Block* (Upper/Lower)

(Bearcat/Panther)

40

Idler Wheel/Mounting Block

(Upper/Lower) (Crossfire/M-Series)

34

Idler Wheel/Mounting Block (F-Series/T-Series)

20

Spring Slide Block/Rail (Bearcat/Panther)

40

Spring Slide Block/Rail (Crossfire)

34

Spring Slide Block/Rail (F-Series/T-Series)

20

Pivot Arm/Idler Arm

18

Rear Arm/Rail

40

Rear Axle/Idler Wheel*

(Bearcat/Crossfire/Panther)

40

Rear Axle/Idler Wheel* (M-Series)

50

Rear Axle/Idler Wheel (F-Series/T-Series)

20

Front Arm Mounting Bracket/Rail

(Bearcat/Crossfire/Panther)

30

Front Arm/Rail (F-Series/T-Series)

40

Front Arm/Rail (M-Series)

50

Front Inner Idler Wheel Assy

(Bearcat/Panther)

40

Front Rail Support/Rail*

(Crossfire/M-Series)

30

Front Rail Support/Rail* (F-Series/T-Series)

20

Front Arm/Mounting Bracket (Bearcat/Panther)

40

Front Arm/Mounting Bracket (Crossfire)

34

Limiter Strap

10

Rail Support/Rail* (Bearcat/Panther)

50

Rear Arm/Idler Arm* (M-Series)

45

Rear Arm/Idler Arm (F-Series/T-Series)

40

Rear Arm/Idler Arm (Crossfire)

34

Rear Arm/Idler Arm* (Bearcat/Panther)

40

Track Adjuster Bracket/Rail

10

Rear Arm Limiter/Rail*

50

Front Arm Shock Axle/Rail

40

Rear Shock Pivot/Front Arm (F-Series)

20

Front Shock Pivot Axle

40

Rear Arm Shock Pivot/Idler Wheel Assembly

(T-Series)

20