Snowmobile Arctic Cat (2002 year). Manual - part 113

8-10

6. Either test drive the snowmobile or run the engine

for five minutes; then tighten the drive clutch bolt

to 6.9-7.6 kg-m (50-55 ft-lb).

REPLACING CAM ARM BUSHINGS

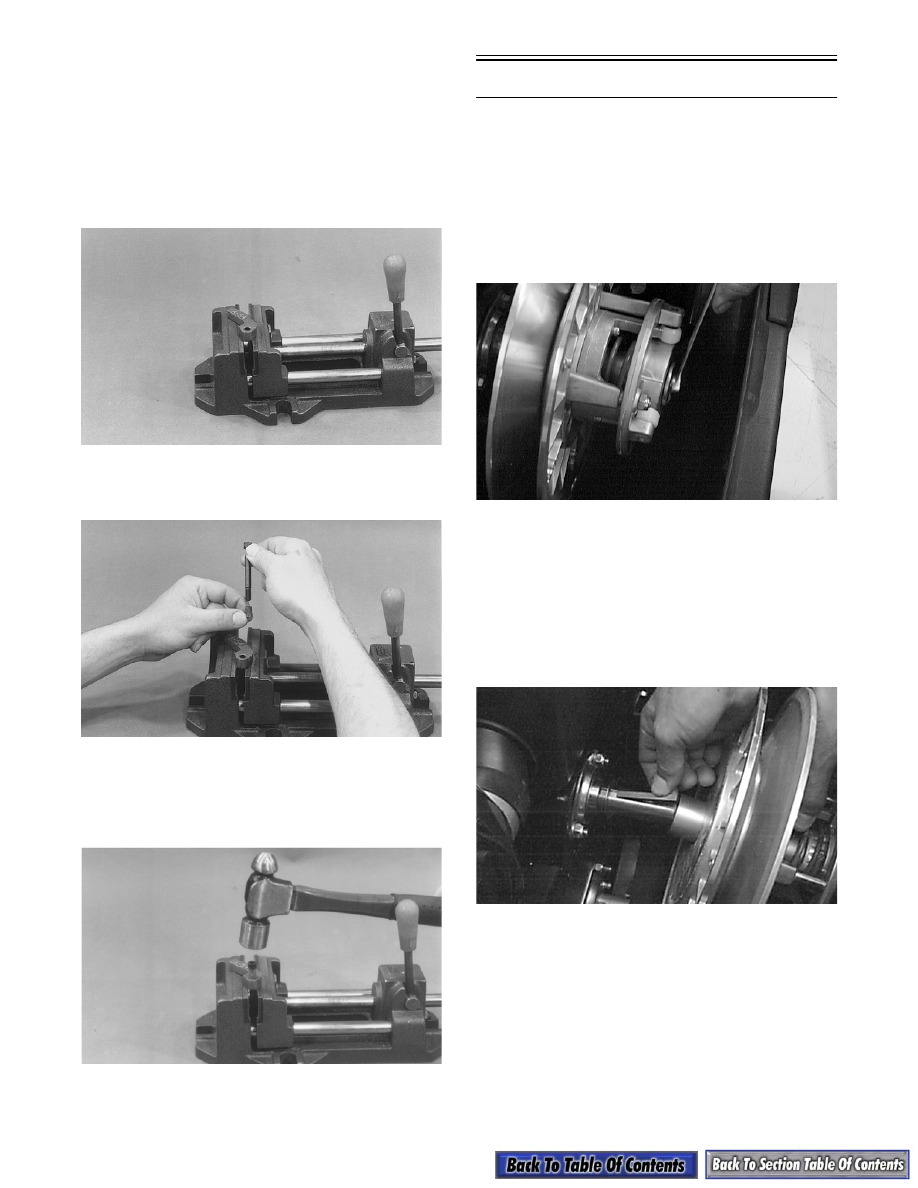

1. Using a vise, spread the jaws just enough to allow

room for the bushing to pass between.

2. Position the cam arm over the spread jaws.

AM094

3. Slide a new bushing onto one of the cam arm pins;

then position the pin through the cam arm bushing.

AM095

4. Using the new bushing as a tool, drive the worn

bushing from the cam arm. When the head of the

cam arm pin contacts the cam arm, the new

bushing will be properly seated.

AM096

Driven Pulley

REMOVING

1. Open the hood; then open the belt guard.

2. Remove the drive belt.

3. Remove the cap screw and washer securing the

driven pulley; then account for and note the

position of any alignment washers.

SC013D

4. Slide the driven pulley off the driven shaft; then

remove pulley from the engine compartment.

NOTE: If the driven pulley is tight on the shaft,

pull the driven pulley off using the Driven Pulley

Puller (p/n 0744-023).

5. Remove the key, alignment washers, and stub

shaft from the driven shaft.

AF120D