Snowmobile Polaris Widetrak LX (2014 year). Manual - part 21

85

MAINTENANCE

Clutch System

Drive Belt Deflection

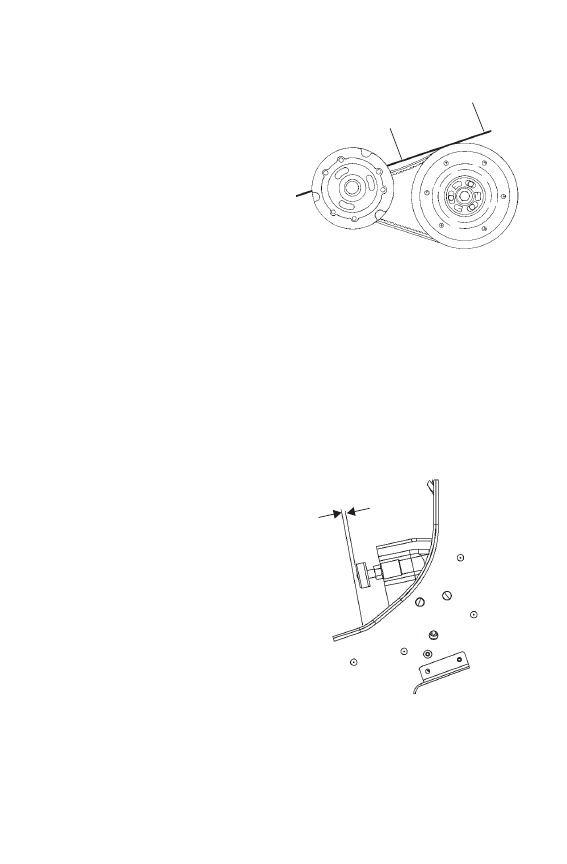

Measure belt deflection with

both clutches at rest and in their

full neutral position.

Place a straight edge on the belt

(1) and apply downward

pressure while measuring at

point 2. This measurement

should be 1 1/4 inches (32 mm).

Drive Belt Adjustment

Belt deflection should be adjusted without removing the clutch from the

jackshaft.

1. Loosen the 7/16-inch jam nut on the belt width adjuster.

2. Using a 1/8-inch Allen wrench, adjust the threaded set screw as

needed.

Tip: Turn the set screw in (clockwise) to increase the distance between the

sheaves and out (counterclockwise) to decrease the distance.

3. Tighten the jam nut.

Torque Stop

Periodically check torque stop

clearance. With clutches in

proper alignment, the torque stop

clearance should be. 010-.030

inch (.25-.75 mm) from the

engine case.

Adjust if necessary, and lock the

jam nut.

1

2

.010-.030 in.

(.25-.75 mm)