Snowmobile Polaris Trail RMK (2010 year). Manual - part 20

81

MAINTENANCE

Brakes

n

Hydraulic Brake Inspection

Inspect the brake lever reserve before each use of the snowmobile. See

page 45.

Brake pads must be replaced when the brake pad material becomes thin-

ner than the backing plate (approximately 1/16 inch/1.5 mm). A kit is

available for replacing brake pads. See your dealer.

WARNING! Brake failure during operation can result in serious injury or death.

Properly functioning brakes are vital to your safety. Be sure the brake pads do

not drag on the disc and that brake lever travel is not excessive. Always replace

brake pads when the brake pad material becomes thinner than the backing plate

(approximately 1/16 inch/1.5 mm).

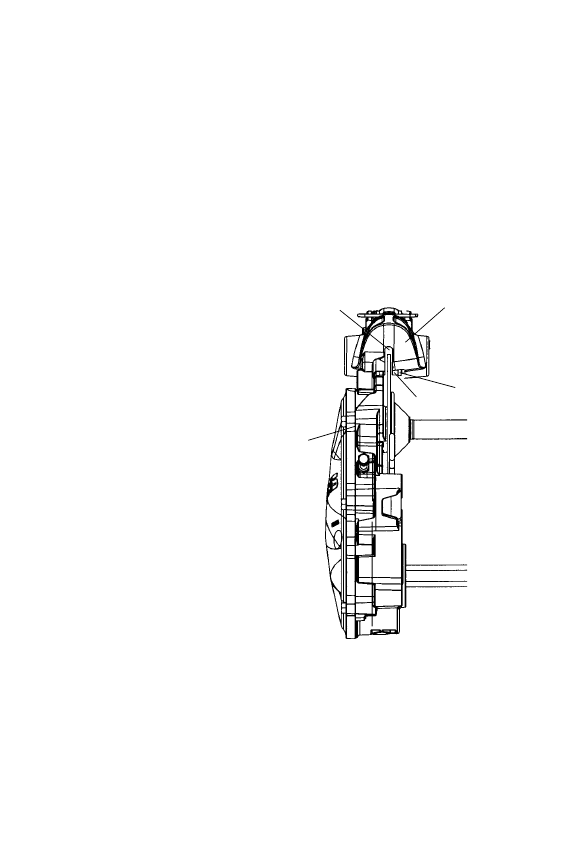

Brake Components

1. Brake Caliper

2. Chaincase

3. Brake Disc

4. Backing Plate

5. Brake Pad Material

(Replace when thickness is

less than 1/16 inch/1.5 mm)

1

2

3

4

5