Snowmobile Polaris (2006 year). Manual - part 42

7.22

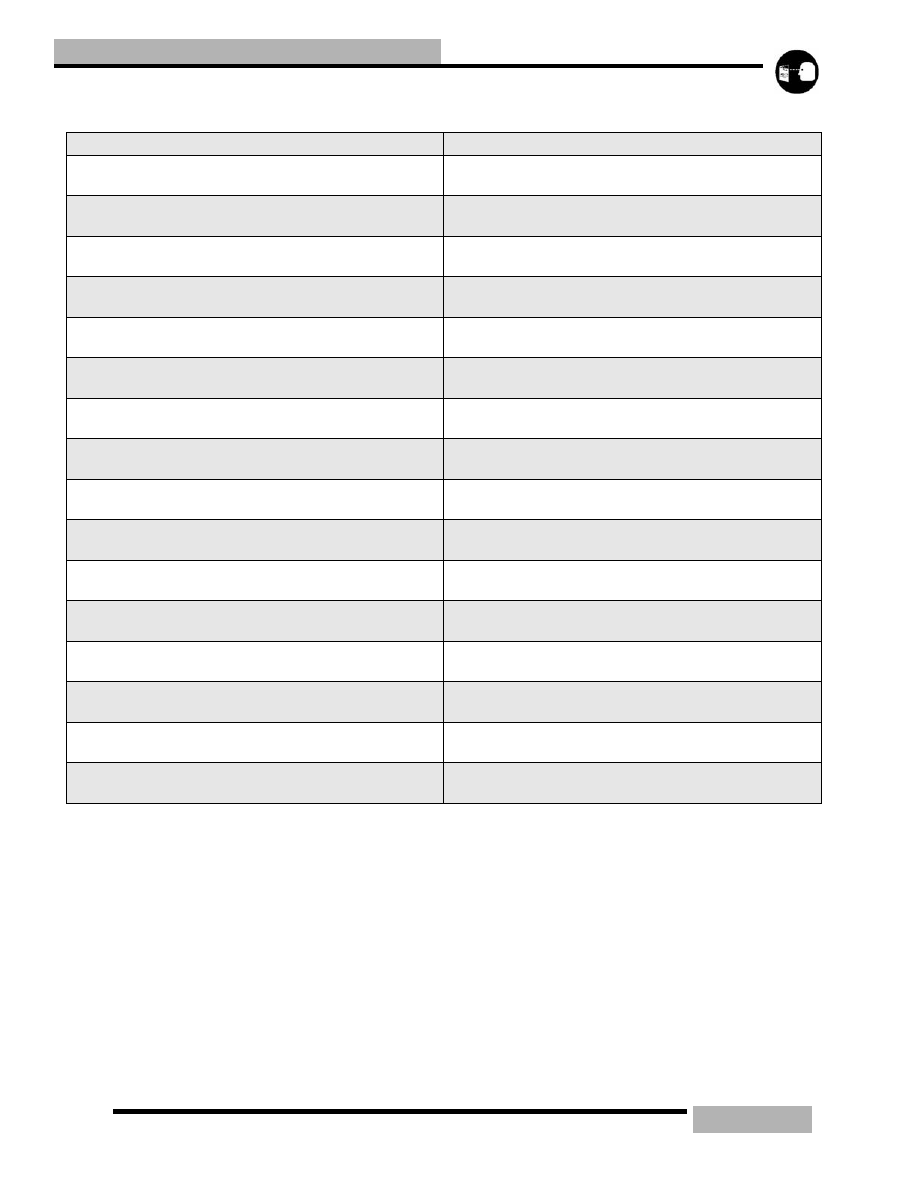

CLUTCHING

Table 7-9: Team Driven Ramps for Non Electric Reverse

PART NUMBER

DESCRIPTION

5133321

66/44-46

70/48-36

5133491

74/48-46

70/48-46

5133492

74/48-46

74/40-46

5133493

72/44-46

72/40-46

5133494

70/44-46

70/40-46

5133495

68/44-46

68/40-46

5133496

66/48-46

66/40-46

5133497

64/44-46

64/40-46

5133498

62/44-46

62/40-46

5133499

58/44-46

58/40-46

5133721

66/44-46

70/48-46

5134566

58/42-36

56/40-40

5134746

64/38-65

66/40-55

5134861

58/34-46

60/34-65

5135375

62/40-46

64/40-55

5135376

64/38-65

64/38-46