Kincaid 8xp. Manual - part 2

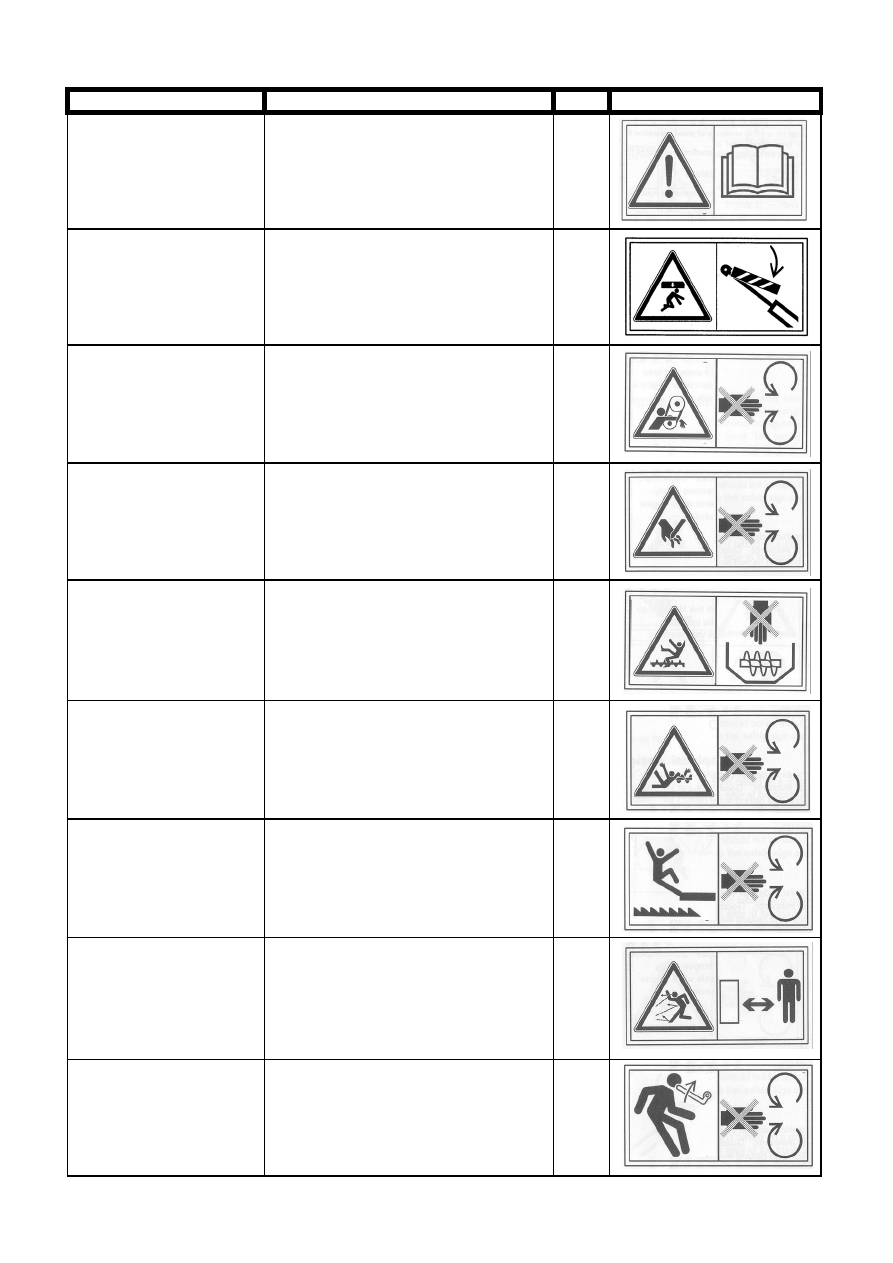

Hazard pictorials

Danger

How to avoid it

Nr.

Symbol

Subject to danger due to

insufficient information

Read the manual before starting the com-

bine

1

A raised part may fall down Support raised parts before going under

them

2

Gap in belt drive

Stop the engine and remove the ignition

key before removing any guards

3

Getting entangled in mov-

ing parts

Stop the engine and remove the ignition

key before removing any guards and/or

reaching into a danger zone

4

Getting entangled in rotat-

ing auge

Stop the engine and remove the ignition

key before removing any guards

5

Getting entangled in rotat-

ing auger

Do not reach into an opening with the en-

gine running

6

Falling into moving machin-

ery

Stop the engine and remove the ignition

key before removing any guards

7

Danger caused by flying

objects

Keep at a safe distance from the combine

8

Kickback or upward motion

of arm handle

Stop the engine and remove the ignition

key before inserting the handle

9

- 11 -