Challenger Terra Gator 3244 Chassis. Manual - part 125

627333-A

8-7

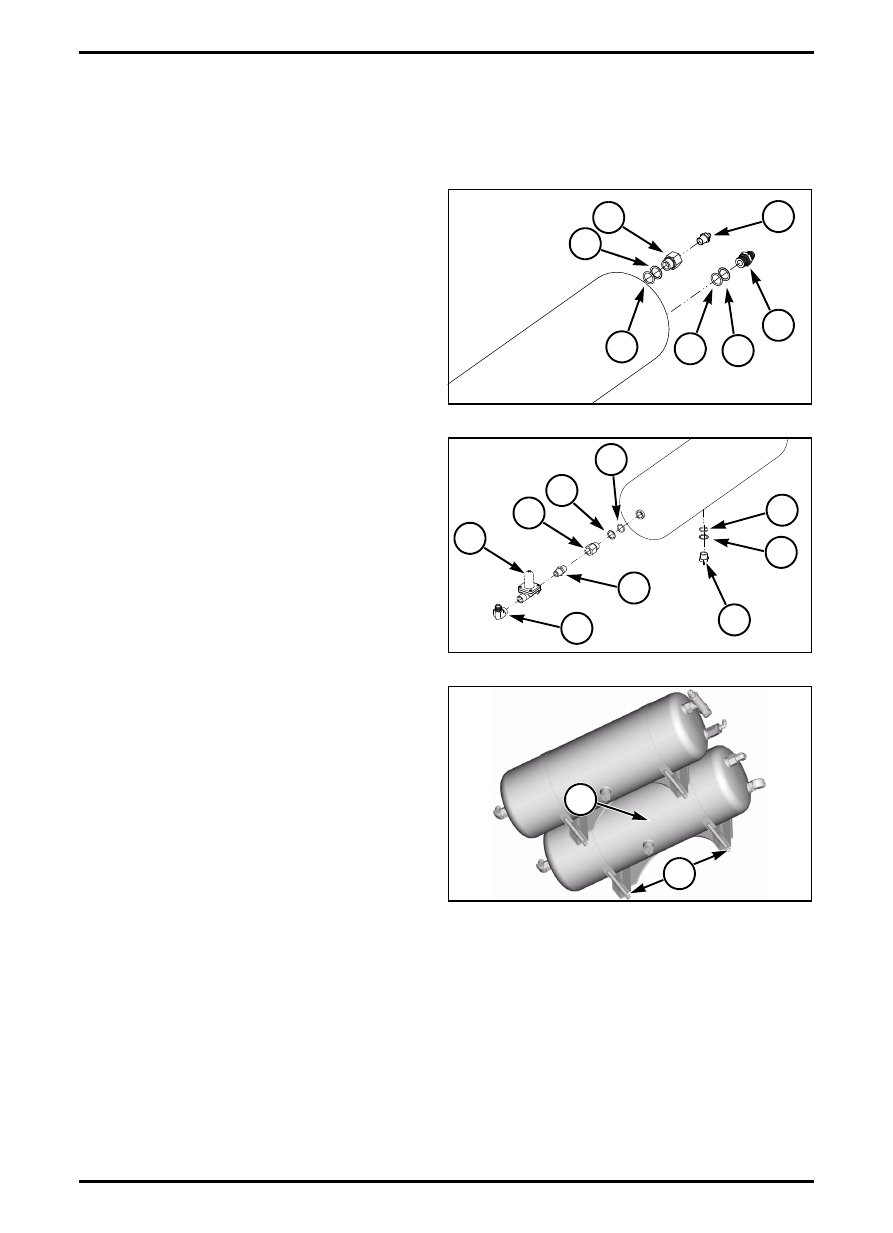

Air Tank and Pressure Control Check Valve

Air Tank Installation

NOTE: For example ew use the wet air tank.

NOTE: Always use new O-rings and O-ring washers.

NOTE: Be sure to apply a thin film of oil to the O-rings

on all fittings.

FIG. 4: Install 3/4-16 MJIC straight adapter (1) into

inlet port with M22 O-ring (2) and M22 trust washer (3).

Install 3/8 MNPT x 1/4 MJIC adapter (4) into a

M22-1-1/2 OR x 3/8 FNPT adapter (5). Install this

assembly into output port on rear of tank with M22

O-ring (6) and M22 trust washer (7).

FIG. 5: Install drain valve (1) into port in bottom of tank

with M22 O-ring (2) and M22 trust washer (3).

Install 8 FNPT x 8 MJIC 90-degree fitting (4) onto outlet

port of PCCV (5). Tighten fitting until vertical and

pointing upward. Install 0.50NPT nipple (6) into inlet

port of PCCV.

Install 0.50NPT adapter (7) into outlet port with M22

O-ring (8) and M22 trust washer (9).

Install PCCV assembly into outlet adapter (7). Tighten

assembly until 90-degree fitting is vertical and pointing

upward.

FIG. 6: Bolt tank and clamp assembly (1) onto

mounting brackets under frame with four nuts (2).

Mount hose support to front clamp and tighten nut.

FIG. 4

N081612003

7

2

3

1

6

5

4

FIG. 5

N081612003

1

3

2

4

5

7

6

9

8

FIG. 6

1

q000177s

2