Challenger Terra Gator 3244 Chassis. Manual - part 113

627333-A

5-45

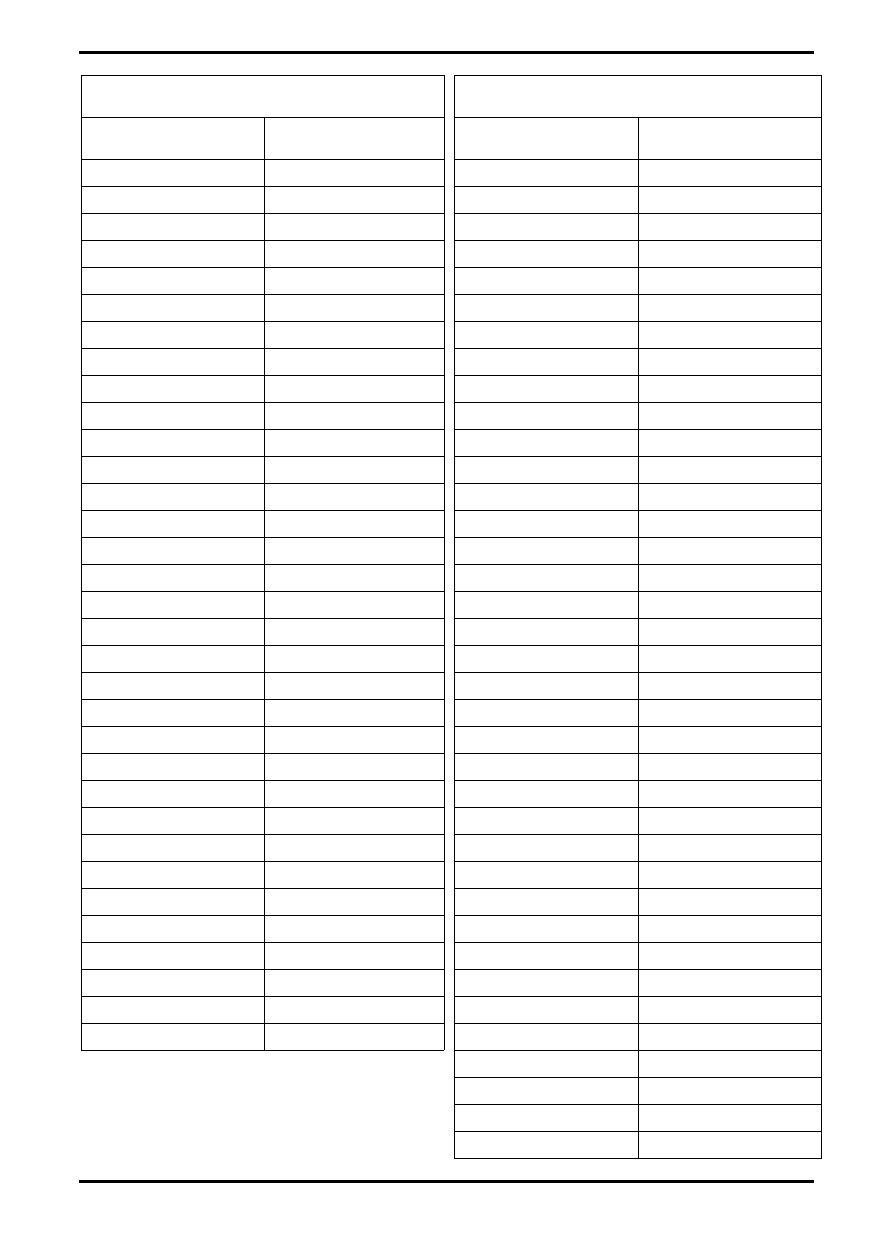

HVAC Testing and Adjusting

Relationship Between Temperature and Pressure

(R-134a Refrigerant)

Temperature Degrees C

(degrees F)

Pressure kPa (PSI)

−18 C (0.0 F)

44 kPa (6.4 PSI)

−17 C (2.0 F)

51 kPa (7.4 PSI)

−16 C (4.0 F)

59 kPa (8.5 PSI)

−14 C (6.0 F)

66 kPa (9.6 PSI)

−13 C (8.0 F)

74 kPa (10.7 PSI)

−12 C (10.0 F)

82 kPa (11.9 PSI)

−11 C (12.0 F)

90 kPa (13.1 PSI)

−10 C (14.0 F)

99 kPa (14.3 PSI)

−9 C (16.0 F)

108 kPa (15.6 PSI)

−8 C (18.0 F)

117 kPa (17.0 PSI)

−7 C (20.0 F)

127 kPa (18.4 PSI)

−6 C (21.0 F)

132 kPa (19.1 PSI)

−6 C (22.0 F)

137 kPa (19.8 PSI)

−5 C (23.0 F)

141 kPa (20.5 PSI)

−4 C (24.0 F)

147 kPa (21.3 PSI)

−4 C (25.0 F)

152 kPa (22.0 PSI)

−3 C (26.0 F)

157 kPa (22.8 PSI)

−3 C (27.0 F)

163 kPa (23.6 PSI)

−2 C (28.0 F)

168 kPa (24.4 PSI)

−2 C (29.0 F)

174 kPa (25.2 PSI)

−1 C (30.0 F)

179 kPa (26.0 PSI)

−1 C (31.0 F)

185 kPa (26.8 PSI)

0 C (32.0 F)

191 kPa (27.7 PSI)

1 C (33.0 F)

197 kPa (28.5 PSI)

1 C (34.0 F)

203 kPa (29.4 PSI)

2 C (35.0 F)

209 kPa (30.3 PSI)

2 C (36.0 F)

215 kPa (31.2 PSI)

3 C (37.0 F)

221 kPa (32.1 PSI)

3 C (38.0 F)

228 kPa (33.0 PSI)

4 C (39.0 F)

234 kPa (34.0 PSI)

4 C (40.0 F)

241 kPa (34.9 PSI)

5 C (41.0 F)

248 kPa (35.9 PSI)

6 C (42.0 F)

254 kPa (36.9 PSI)

Relationship Between Temperature and Pressure

(R-134a Refrigerant)

Temperature Degrees C

(degrees F)

Pressure kPa (PSI)

6 C (43.0 F)

261 kPa (37.9 PSI)

7 C (44.0 F)

263 kPa (38.9 PSI)

7 C (45.0 F)

275 kPa (39.9 PSI)

8 C (46.0 F)

283 kPa (41.0 PSI)

8 C (47.0 F)

290 kPa (42.0 PSI)

9 C (48.0 F)

297 kPa (43.1 PSI)

9 C (49.0 F)

305 kPa (44.2 PSI)

10 C (50.0 F)

312 kPa (45.3 PSI)

11 C (51.0 F)

320 kPa (46.4 PSI)

11 C (52.0 F)

328 kPa (47.5 PSI)

12 C (53.0 F)

336 kPa (48.7 PSI)

12 C (54.0 F)

344 kPa (49.9 PSI)

13 C (55.0 F)

352 kPa (51.0 PSI)

13 C (56.0 F)

360 kPa (52.2 PSI)

14 C (57.0 F)

369 kPa (53.5 PSI)

14 C (58.0 F)

377 kPa (54.7 PSI)

15 C (59.0 F)

385 kPa (55.9 PSI)

16 C (60.0 F)

394 kPa (57.2 PSI)

16 C (61.0 F)

403 kPa (58.2 PSI)

17 C (62.0 F)

412 kPa (59.8 PSI)

17 C (63.0 F)

421 kPa (61.1 PSI)

18 C (64.0 F)

430 kPa (62.4 PSI)

18 C (65.0 F)

440 kPa (63.8 PSI)

19 C (66.0 F)

450 kPa (65.2 PSI)

19 C (67.0 F)

459 kPa (66.8 PSI)

20 C (68.0 F)

469 kPa (68.0 PSI)

21 C (69.0 F)

478 kPa (69.4 PSI)

21 C (70.0 F)

488 kPa (70.8 PSI)

22 C (71.0 F)

498 kPa (72.3 PSI)

22 C (72.0 F)

509 kPa (73.8 PSI)

23 C (73.0 F)

519 kPa (75.3 PSI)

23 C (74.0 F)

530 kPa (76.8 PSI)

24 C (75.0 F)

540 kPa (78.3 PSI)

24 C (76.0 F)

551 kPa (79.9 PSI)

25 C (77.0 F)

562 kPa (81.5 PSI)

26 C (78.0 F)

573 kPa (83.1 PSI)

26 C (79.0 F)

584 kPa (84.7 PSI)