Challenger Terra Gator 3244 Chassis. Manual - part 29

627333-A

3-29

Testing and Adjusting

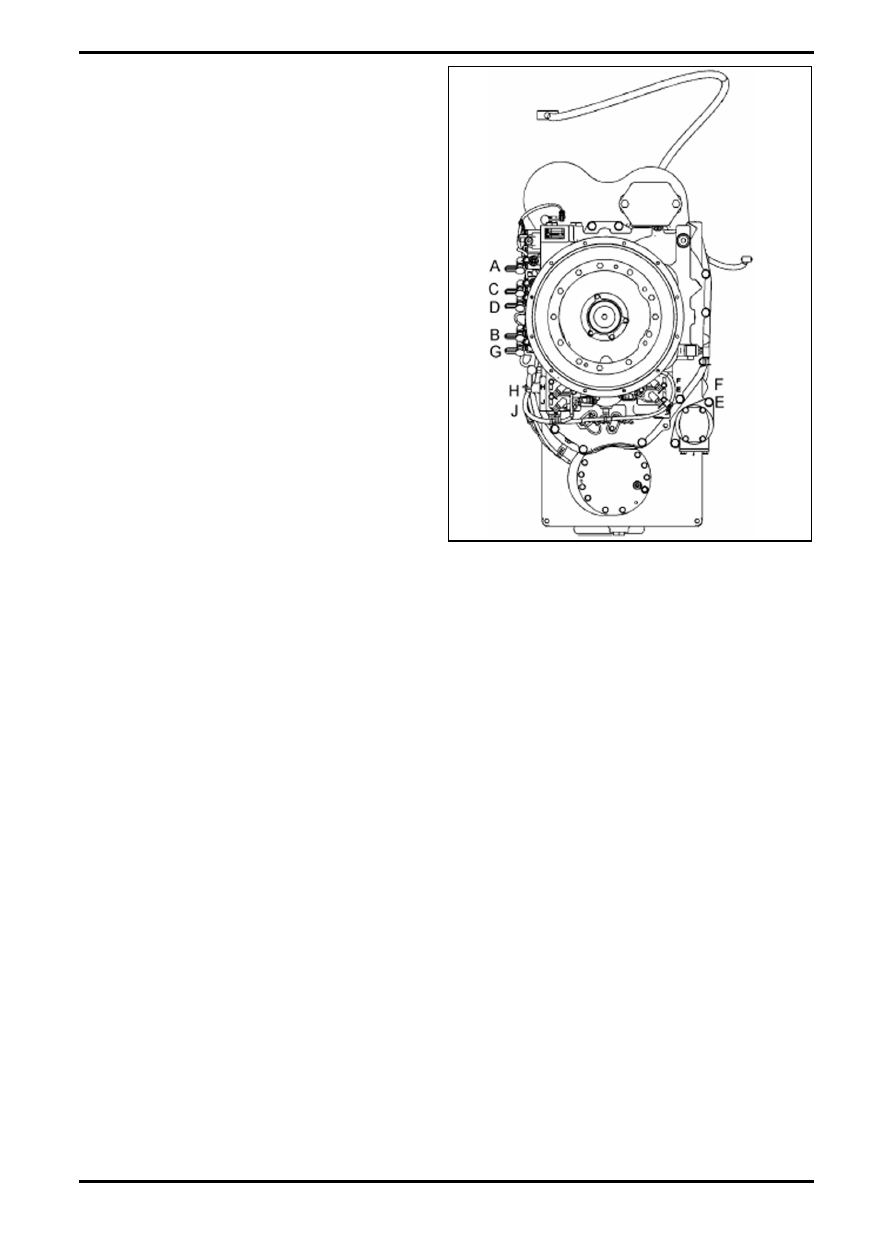

FIG. 11: Modulating Valves

Each modulating valve has a designated letter, as

shown. The letters have been cast into the

transmission housing.

Log the clutch pressures in the table on the next page.

There are always two clutches that are engaged for

each gear selection. Neutral position only uses one

clutch. See the table in order to determine the clutches

that are engaged for gear selection.

FIG. 11

Q000051S