Nissan Murano Z51 (2013 year). Manual - part 94

WCS

BCM (BODY CONTROL MODULE)

WCS-67

< ECU DIAGNOSIS INFORMATION >

C

D

E

F

G

H

I

J

K

L

M

B

A

O

P

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

FAIL-SAFE CONTROL BY RAIN SENSOR MALFUNCTION

• BCM judges the rain sensor serial link error by the rain sensor serial link condition and detects the rain sen-

sor malfunction by rain sensor malfunction signal.

• When BCM detects the rain sensor serial link error or the rain sensor malfunction while front wiper AUTO

operation, BCM operates a fail-safe control.

NOTE:

If rain sensor malfunction is detected when ignition switch is turned OFF

⇒

ON and front wiper switch is INT/

AUTO position, BCM operates a fail-safe control.

REAR WIPER MOTOR PROTECTION

BCM detects the rear wiper stopping position according to the rear wiper stop position signal.

When the rear wiper stop position signal does not change for more than 5 seconds while driving the rear

wiper, BCM stops power supply to protect the rear wiper motor.

Condition of cancellation

1.

More than 1 minute is passed after the rear wiper stop.

2.

Turn rear wiper switch OFF.

3.

Operate the rear wiper switch or rear washer switch.

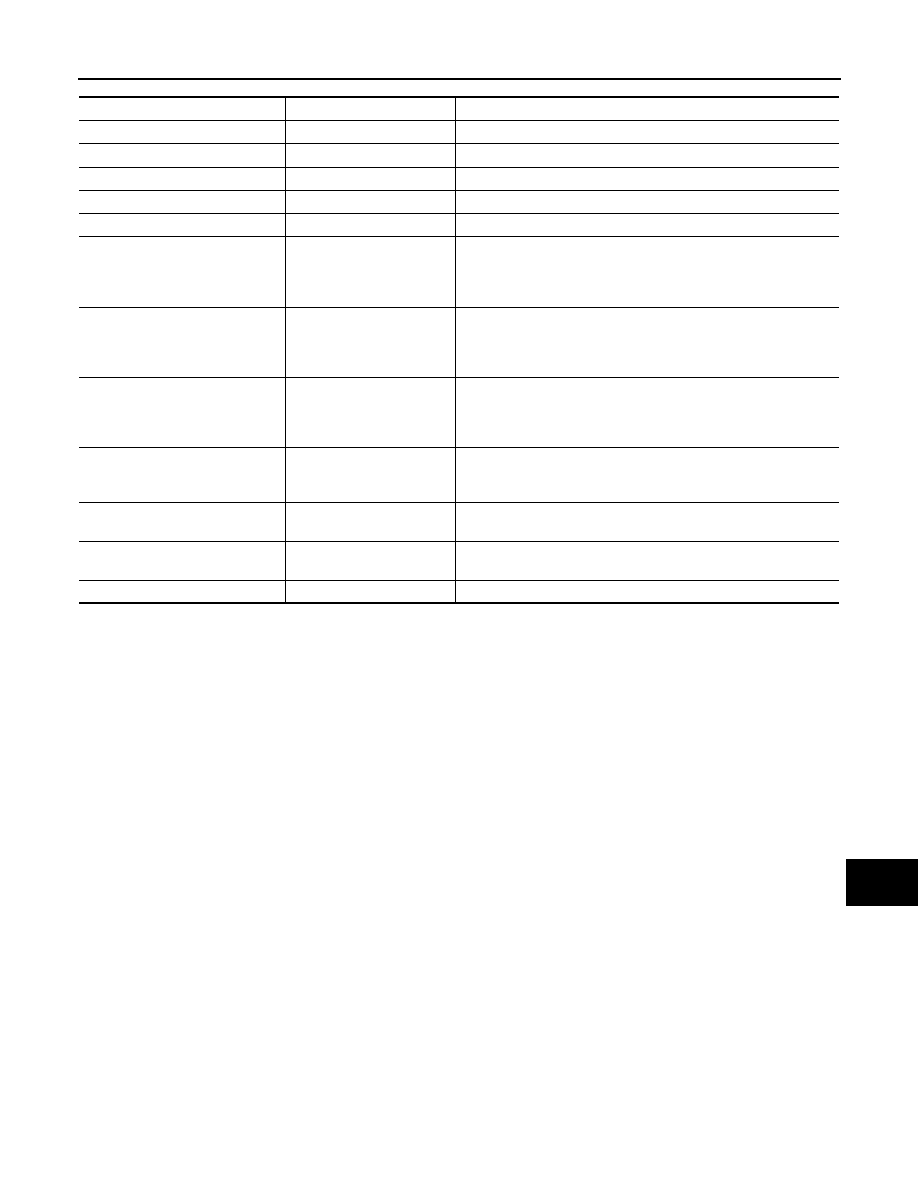

DTC Inspection Priority Chart

INFOID:0000000008946115

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

Display contents of CONSULT

Fail-safe

Cancellation

B2190: NATS ANTENNA AMP

Inhibit engine cranking

Erase DTC

B2191: DIFFERENCE OF KEY

Inhibit engine cranking

Erase DTC

B2192: ID DISCORD BCM-ECM

Inhibit engine cranking

Erase DTC

B2193: CHAIN OF BCM-ECM

Inhibit engine cranking

Erase DTC

B2195: ANTI SCANNING

Inhibit engine cranking

Ignition switch ON

→

OFF

B2560: STARTER CONT RELAY

Inhibit engine cranking

500 ms after the following CAN signal communication status be-

comes consistent

• Starter control relay signal

• Starter relay status signal

B2608: STARTER RELAY

Inhibit engine cranking

500 ms after the following signal communication status becomes

consistent

• Starter motor relay control signal

• Starter relay status signal (CAN)

B260A: IGNITION RELAY

Inhibit engine cranking

500 ms after the following conditions are fulfilled

• IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

• Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

• Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOST

Maintains the power supply

position attained at the time

of DTC detection

When any of the following conditions are fulfilled

• Power position changes to ACC

• Receives engine status signal (CAN)

B2617: STARTER RELAY CIRC

Inhibit engine cranking

1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM

Inhibit engine cranking

1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B261E: VEHICLE TYPE

Inhibit engine cranking

BCM initialization

Revision: 2012 September

2013 MURANO