Nissan Murano Z51 (2013 year). Manual - part 84

ST-52

< REMOVAL AND INSTALLATION >

[WITH HEATED STEERING WHEEL]

STEERING GEAR AND LINKAGE

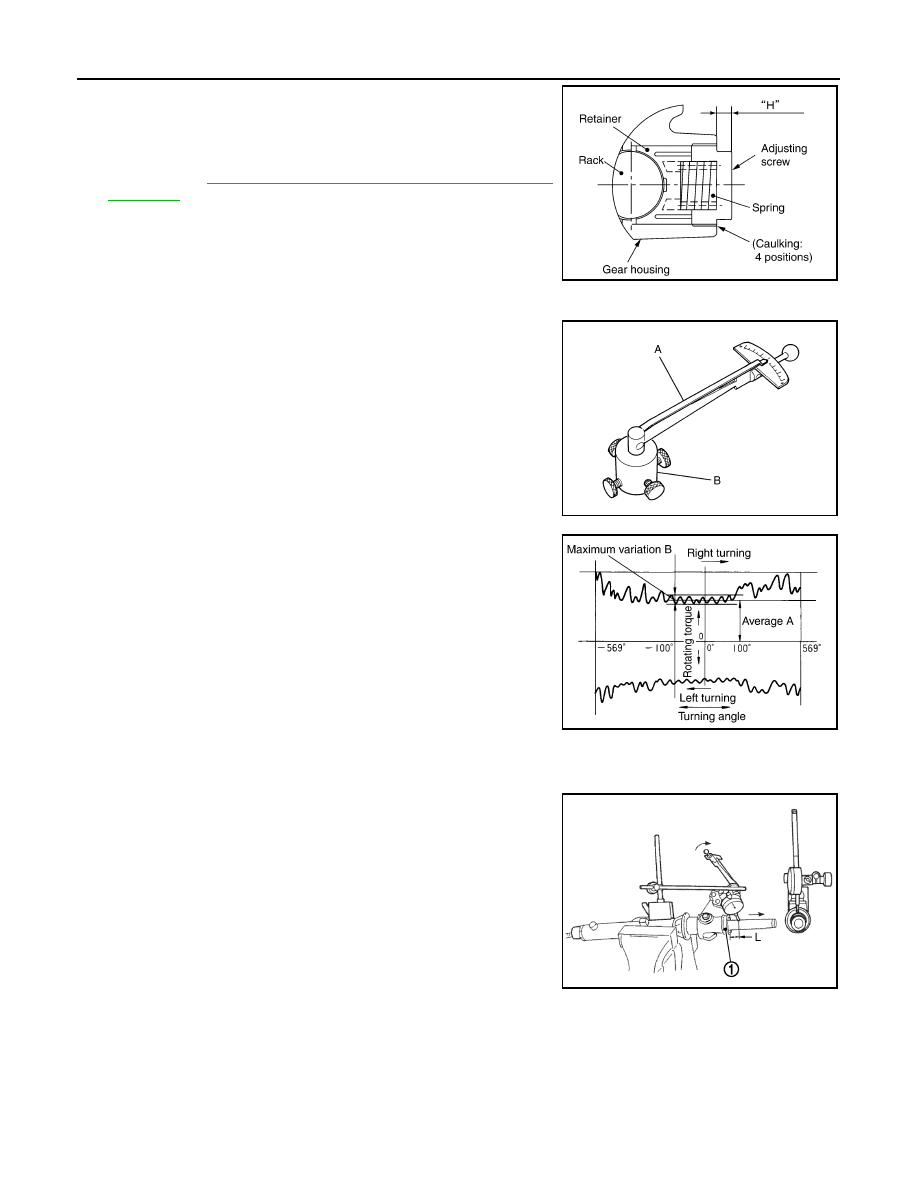

12. Apply recommended thread locking sealant to the thread (2

turns thread), and then screw in the adjusting screw until it

reaches height “H” from gear housing assembly measured

before disassembling.

Use Genuine High Performance Thread Sealant or equiva-

lent. Refer to

GI-22, "Recommended Chemical Products and

13. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

14. Adjust pinion rotating torque with the following procedure.

a.

Measure pinion rotating torque within

±

180

°

of neutral position

of the rack assembly using Tools. Stop the gear at the point

where highest torque is read.

b.

Loosen adjusting screw and retighten to 5.4 N·m (0.55 kg-m, 48

in-lb), and then loosen by 20 to 40

°

.

c.

Measure pinion rotating torque using Tools to make sure that the

measured value is within the standard. Readjust if the value is

outside the standard. Replace steering gear assembly, if the

value is outside the standard after readjusting, or adjusting

screw rotating torque is 5 N·m (0.51 kg-m, 44 in-lb) or less.

d.

Apply recommended liquid gasket to inner socket and turn pinion fully to left with inner socket installed to

gear housing assembly.

e.

Install dial gauge at 5 mm (0.20 in) (L) from the edge of gear

housing assembly (1), and tooth point.

f.

Measure vertical movement of rack assembly when pinion is

turned clockwise with torque of 19.6 N·m (2.0 kg-m, 14 ft-lb).

Readjust adjusting screw angle if the measured value is outside

the standard.

• If reading is outside of the specification, readjust screw angle

with adjusting screw.

CAUTION:

• If reading is still outside of specification, or if the rotating torque of adjusting screw is less

than 5 N·m (0.51 kg-m, 44 in-lb), replace steering gear assembly.

• Never turn adjusting screw more than twice.

• Replace steering gear assembly when adjusting screw is removed or turned more than twice.

SGIA0624E

A: Preload gauge [SST: ST3127S000 (J-25765-A)]

B: Preload adapter [SST: KV48103400 (

—

)]

SGIA1383E

Pinion rotating torque

Around neutral position

(within

±

100

°

) average (A)

: 1.59 – 2.0 N·m (0.17 –

0.20 kg-m, 14 – 17 in-lb)

Maximum variation (B)

: 0.39 N·m (0.04 kg-m, 3.0

in-lb)

Vertical movement

: 0.265 mm (0.0104 in)

SGIA0936E

JSGIA0104ZZ

Revision: 2012 September

2013 MURANO