Nissan Murano Z51 (2013 year). Manual - part 54

PCS

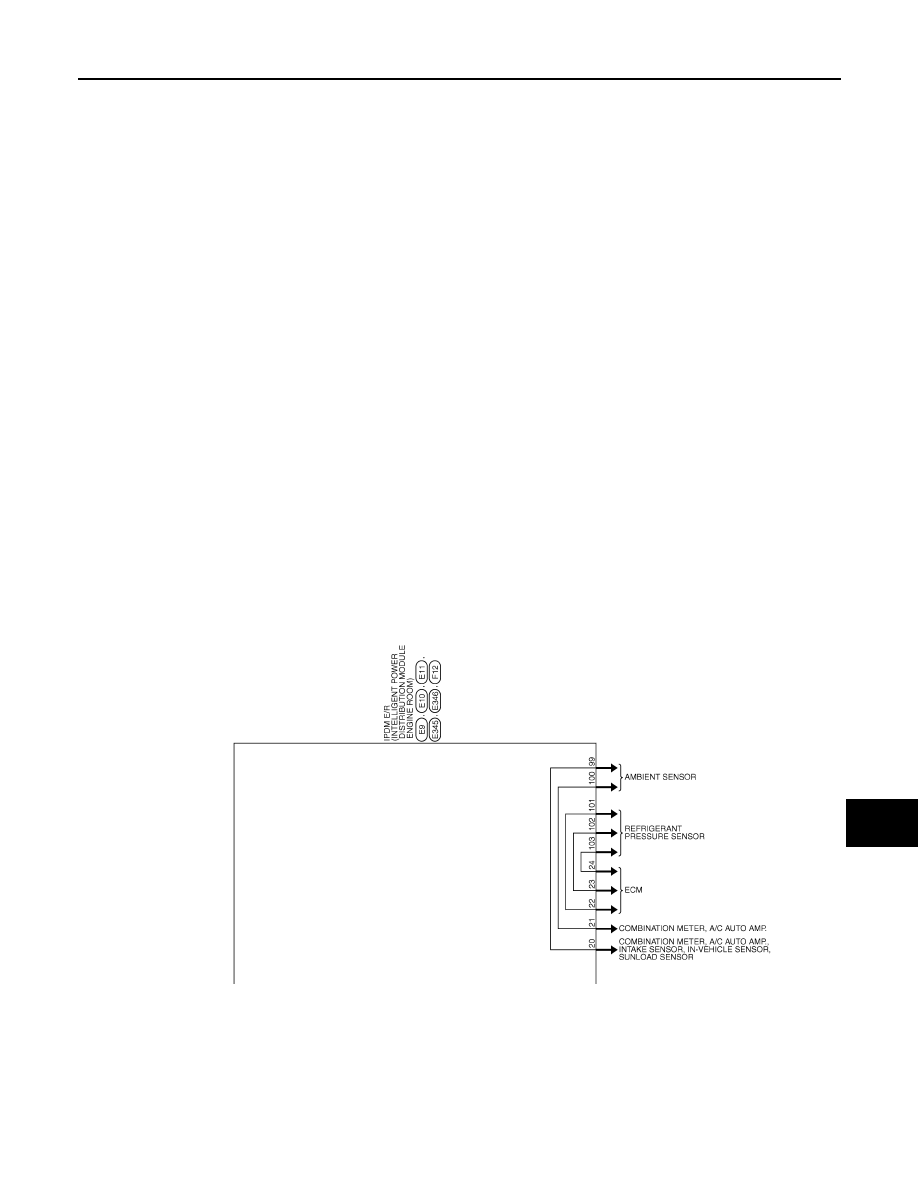

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-29

< ECU DIAGNOSIS INFORMATION >

[IPDM E/R]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

Fail-safe

INFOID:0000000008455187

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

JRMWC5031GB

Revision: 2012 September

2013 MURANO