Nissan Murano Z51 (2013 year). Manual - part 44

MIR-44

< REMOVAL AND INSTALLATION >

[WITH ADP]

INSIDE MIRROR

REMOVAL AND INSTALLATION

INSIDE MIRROR

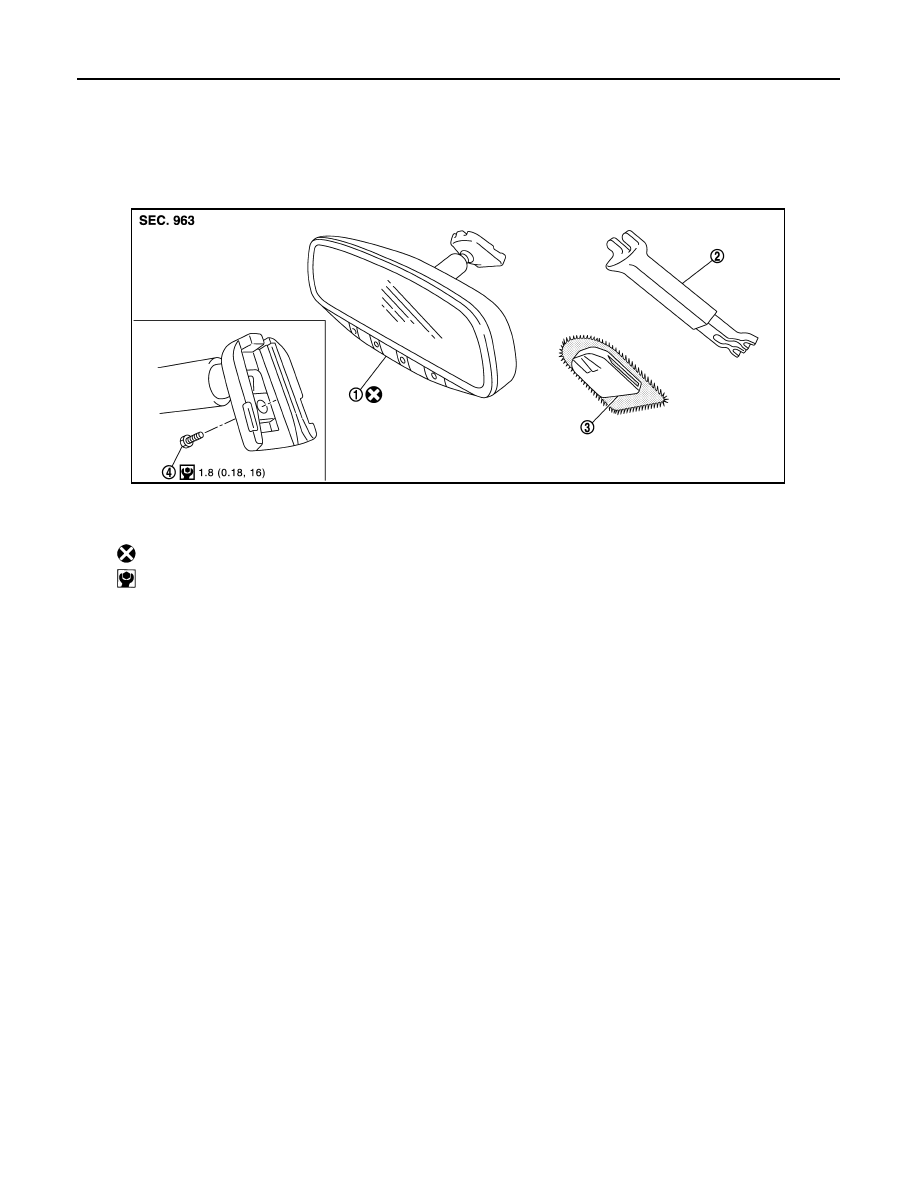

Exploded View

INFOID:0000000008455791

Removal and Installation

INFOID:0000000008455792

CAUTION:

Never reuse the inside mirror disassembled from mirror base.

REMOVAL

1.

Remove the inside mirror cover.

2.

Remove TORX bolt.

3.

Slide the inside mirror upward to remove.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

When inserting the inside mirror into the mirror base, be sure to push the pawl until it get connected to

the mirror base.

1.

Inside mirror

2.

Inside mirror cover

3.

Mirror base

4.

TORX bolt

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

JMLIA0136GB

Revision: 2012 September

2013 MURANO