Nissan Murano Z51 (2013 year). Manual - part 30

FL-10

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

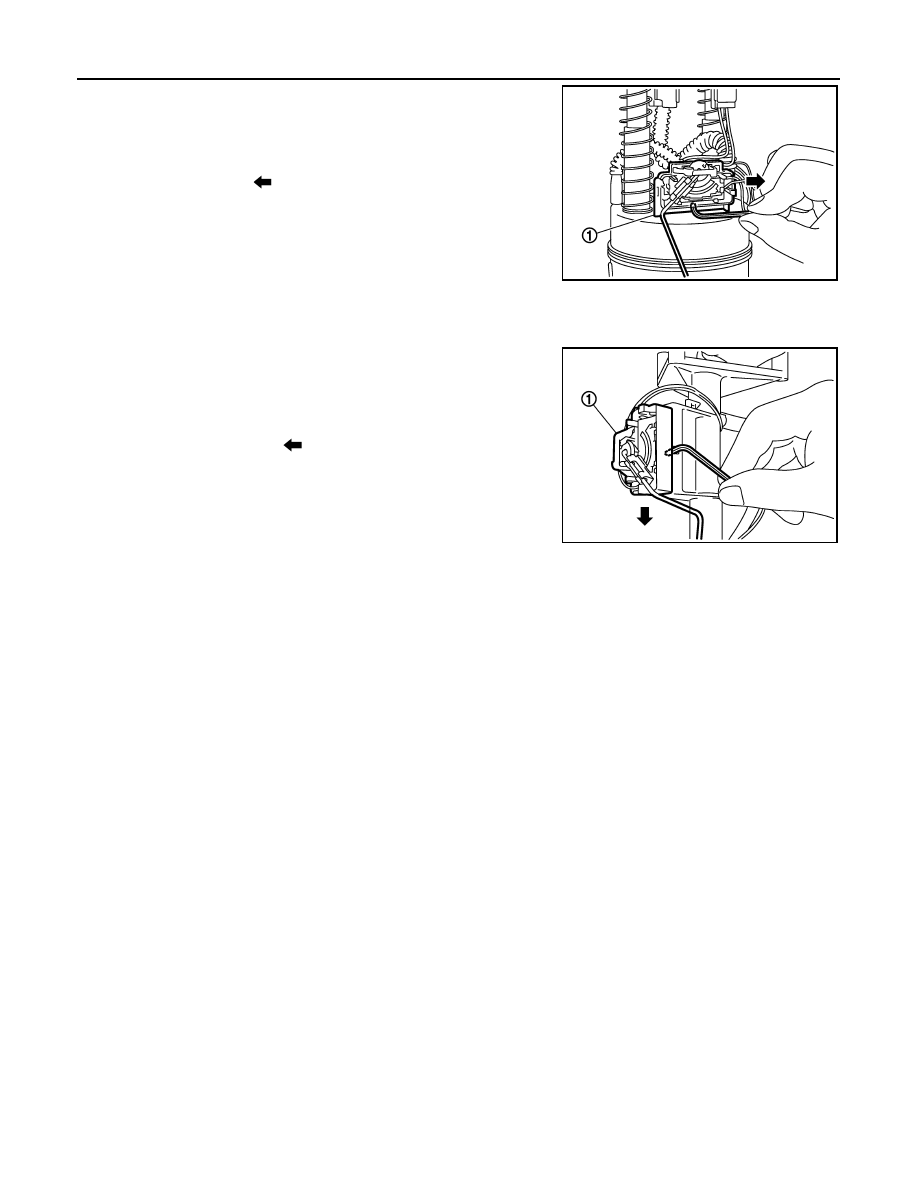

a.

Push the pawl of fuel level sensor unit (1) mounting area with an

L-shaped iron rod or an equivalent to unlock.

CAUTION:

Be careful not to damage it.

b.

With the fuel level sensor unit unlocked, slide it in the direction

shown by the arrow (

).

Sub fuel level sensor unit assembly side

1.

Remove sub fuel level sensor unit according to the following procedure.

a.

Push the pawl of sub fuel level sensor unit (1) mounting area

with an L-shaped iron rod or an equivalent to unlock.

CAUTION:

Be careful not to damage it.

b.

With the sub fuel level sensor unit unlocked, slide it in the direc-

tion shown by the arrow (

).

ASSEMBLY

Install fuel level sensor unit and sub fuel level sensor unit according to the following procedure.

• Insert fuel level sensor unit and sub fuel level sensor unit all the way to the end until a “click” touch and

sound can be recognized.

• Pull fuel level sensor unit and sub fuel level sensor unit in the removal direction to ensure that they do not

become detached.

Inspection

INFOID:0000000008457787

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1.

Turn ignition switch “ON” (with engine stopped), then check connections for leakage by applying fuel pres-

sure to fuel piping.

2.

Start engine and let it idle and check there are no fuel leakage at the fuel system connections.

PBIC4900J

PBIC4899J

Revision: 2012 September

2013 MURANO