Nissan Murano Z51 (2013 year). Manual - part 29

FRONT DRIVE SHAFT

FAX-47

< REMOVAL AND INSTALLATION >

[AWD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

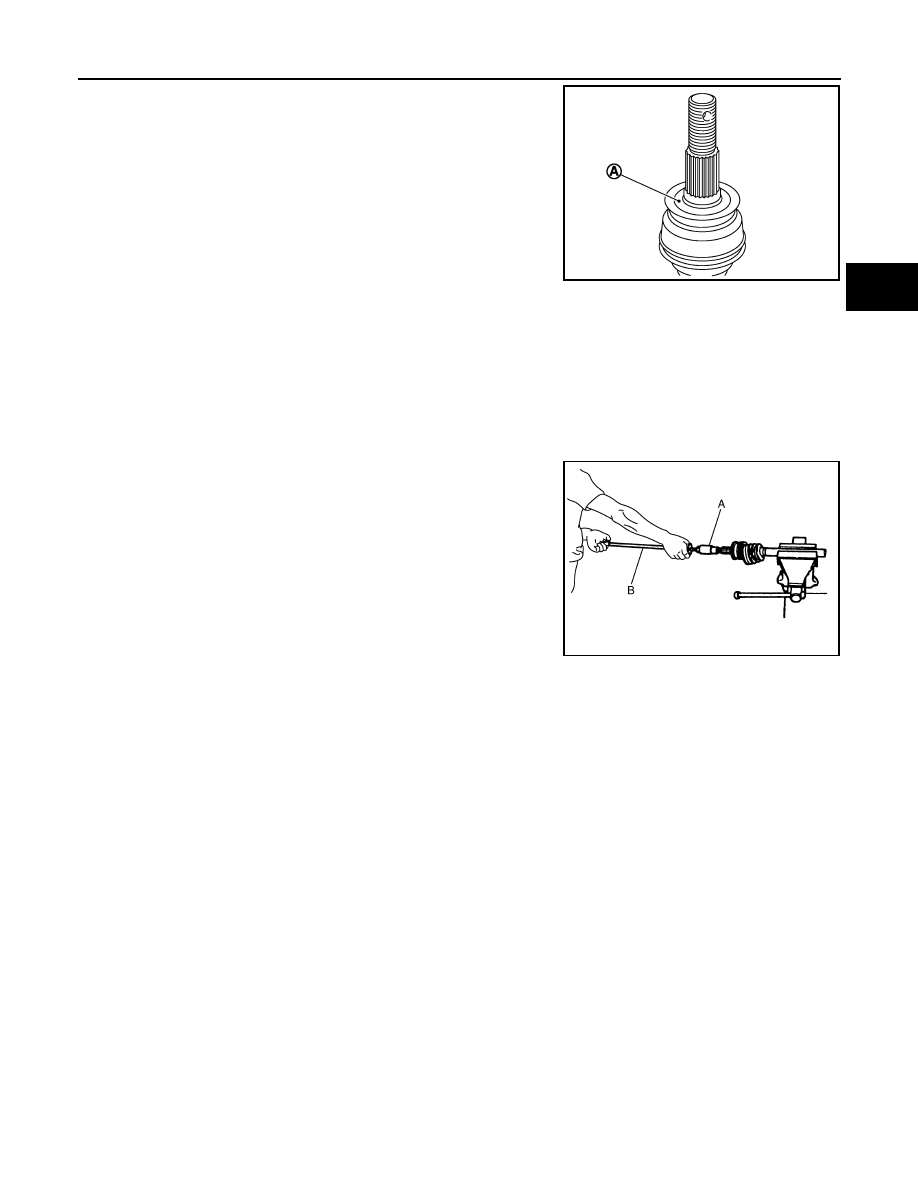

Apply paste [service parts (440037S000)] to cover entire flat

surface (A) of joint sub-assembly of drive shaft.

• Never use a power tool to tighten the wheel hub lock nut.

• Perform the final tightening of each of parts under unladen condi-

tions, which were removed when removing wheel hub and bearing

assembly and axle housing.

• Never reuse cotter pin.

WHEEL SIDE

WHEEL SIDE : Disassembly and Assembly

INFOID:0000000008456088

DISASSEMBLY

1.

Fix shaft with a vise.

CAUTION:

Protect shaft using aluminum or copper plates when fixing with a vise.

2.

Remove boot bands, and then remove boot from joint sub-assembly.

3.

Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from housing assembly.

CAUTION:

• Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

• If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

4.

Remove circular clip (1) from housing assembly.

5.

Remove boot from housing assembly.

ASSEMBLY

1.

Clean the old grease on joint sub-assembly with paper waste.

2.

Fill serration slot joint sub-assembly with NISSAN genuine grease or equivalent until the serration slot and

ball groove become full to the brim.

CAUTION:

After applying grease, use a paper waste to wipe off old grease that has oozed out.

3.

Install boot and boot bands to housing assembly.

CAUTION:

• Wrap serration on housing assembly with tape to protect the boot from damage.

• Never reuse boot and boot band.

4.

Remove the tape wrapped around the serration on housing assembly.

5.

Position the circular clip on groove at the housing assembly edge.

CAUTION:

Never reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip.

6.

Align both center axles of the housing assembly edge and joint sub-assembly. Then assemble housing

assembly with circular clip joint sub-assembly.

Amount paste

: 1.0 – 3.0 g (0.04 – 0.10 oz)

JPDIG0122ZZ

JPDIF0015ZZ

Revision: 2012 September

2013 MURANO