Nissan Murano Z51 (2012 year). Manual - part 92

WT-32

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis Procedure

INFOID:0000000007544959

1.

POWER SUPPLY SYSTEM CHECK

1.

Turn the ignition switch OFF.

2.

Disconnect the BCM harness connector.

3.

Turn the ignition switch ON.

CAUTION:

Never start the engine.

4.

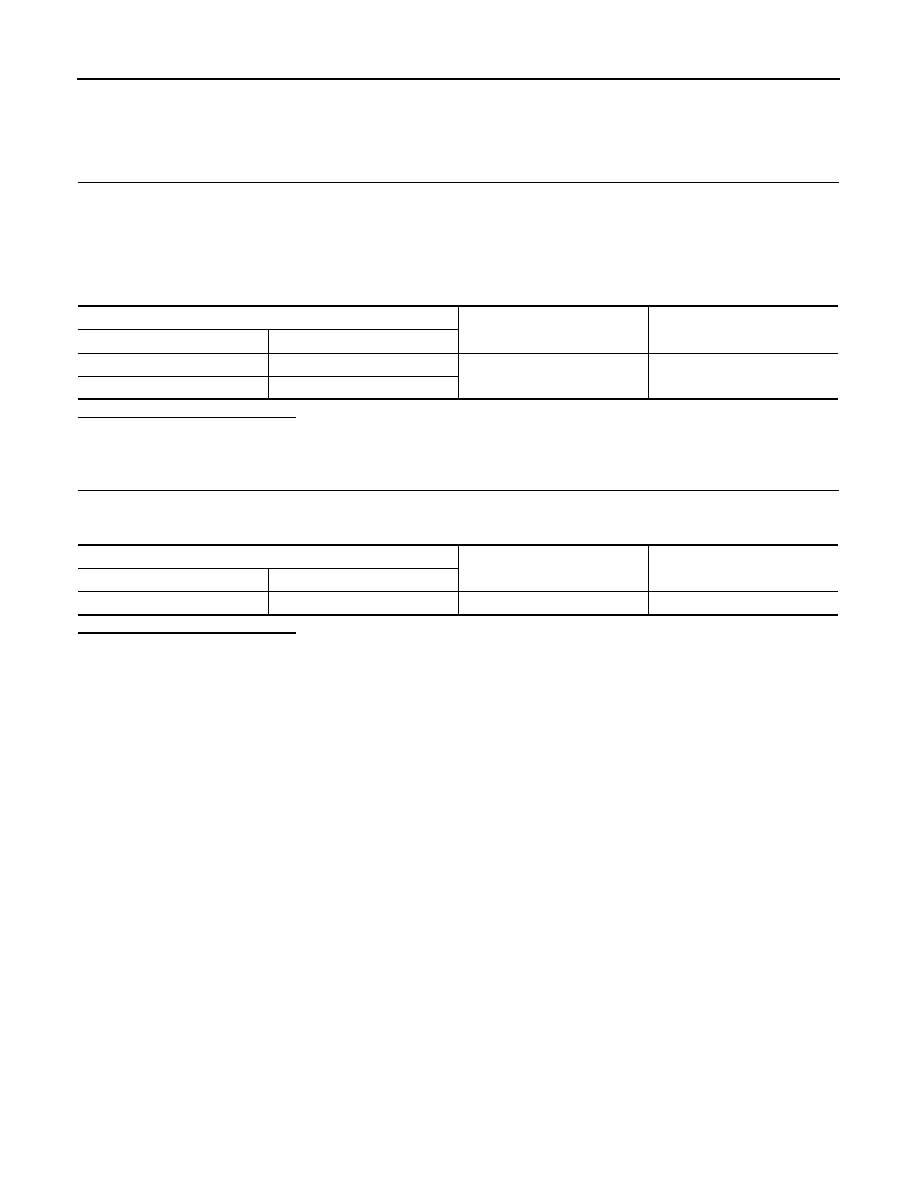

Check the voltage between the BCM harness connector and the ground.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace damaged parts.

2.

GROUND SYSTEM INSPECTION

1.

Turn the ignition switch OFF.

2.

Check the continuity between the BCM harness connector and the ground.

Is the inspection result normal?

YES

>> • Check the 10A fuse [No. 10 in fuse block (J/B)].

• Check the 40A fusible link [No. L in fuse block].

NO

>> Repair or replace damaged parts.

BCM

—

Voltage

Connector

Terminal

M118

1

Ground

Battery voltage

M119

11

BCM

—

Continuity

Connector

Terminal

M119

13

Ground

Existed

Revision: 2013 February

2012 MURANO