Nissan Murano Z51 (2012 year). Manual - part 88

ST-94

< REMOVAL AND INSTALLATION >

[WITHOUT HEATED STEERING WHEEL]

STEERING GEAR AND LINKAGE

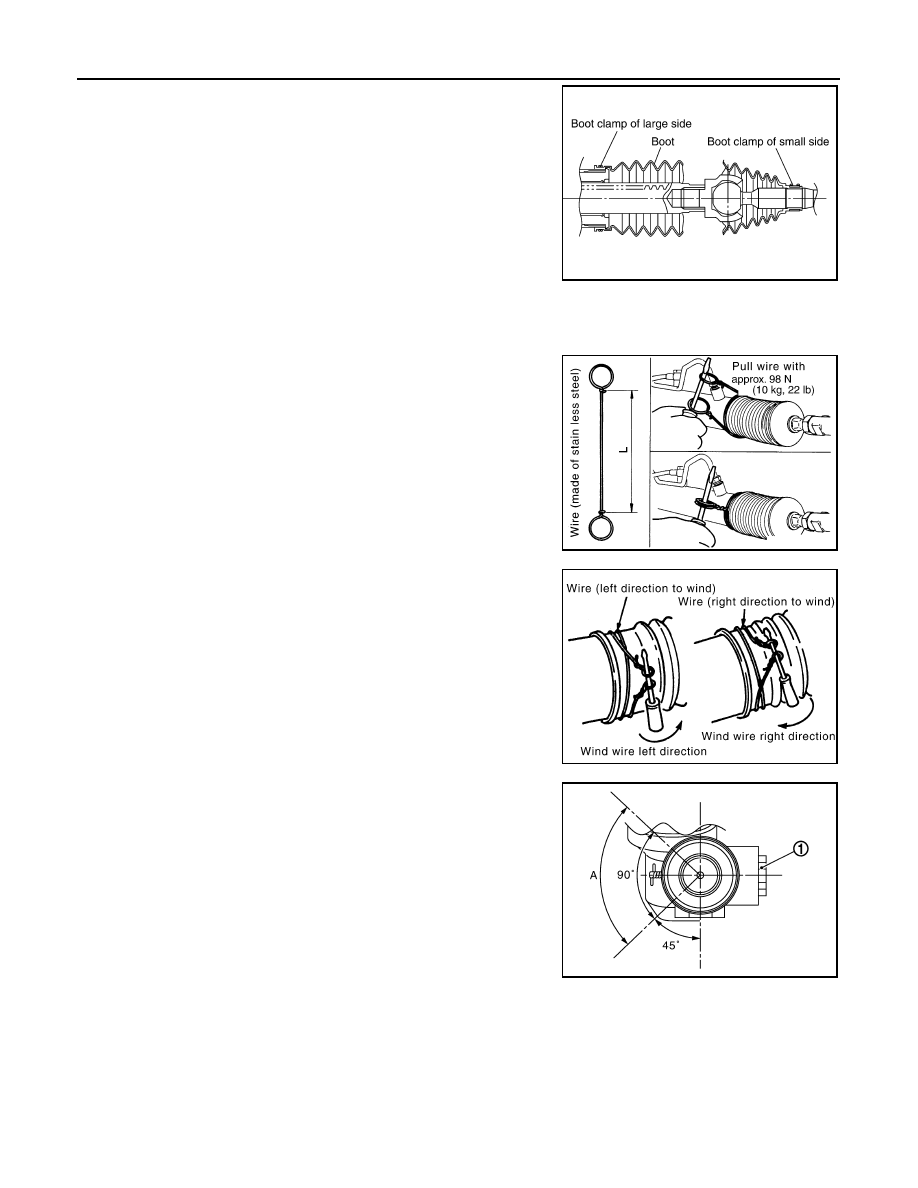

15. Install large end of boot to gear housing assembly.

16. Install small end of boot to inner socket boot mounting groove.

17. Install boot clamp to boot small end.

18. Install boot clamp to the large side of boot with the following procedure.

CAUTION:

Never reuse boot clamp.

a.

Tighten large side of boot with boot clamp (stainless wire).

b.

Wrap clamp around boot groove for two turns. Insert a flat-

bladed screwdriver in loops on both ends of wire. Twist 4 to 4.5

turns while pulling them with force of approximately 98 N (10 kg,

22 lb).

c.

Twist boot clamp as shown. Pay attention to relationship

between winding and twisting directions.

d.

Twisted area (A) of clamp is in the opposite side of adjusting

screw (1) as shown in the figure (to prevent contact with other

parts).

SGIA1325E

Wire length (L)

: 370 mm (14.57 in)

SGIA0163E

SGIA0164E

JSGIA0324ZZ

Revision: 2013 February

2012 MURANO