Nissan Murano Z51 (2012 year). Manual - part 84

ST-30

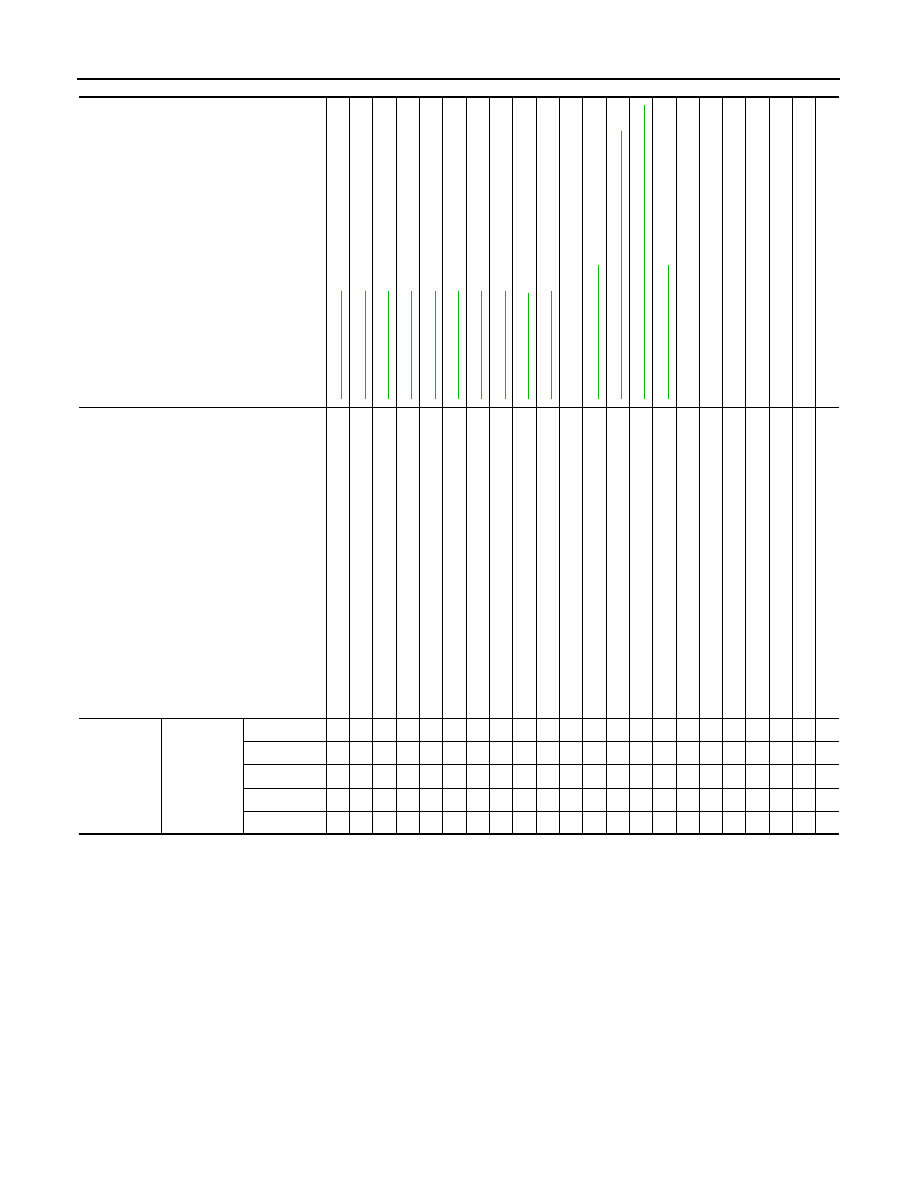

< SYMPTOM DIAGNOSIS >

[WITH HEATED STEERING WHEEL]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference

—

NVH in DLN

section.

NVH in DLN

section.

NVH in F

AX,

RAX, FSU,

RSU section.

NVH in WT

section.

NVH in WT

section.

NVH in F

AX,

RAX

secti

on.

NVH in BR

section.

Possible cause and SUSPECTED PARTS

Fl

ui

d l

e

v

e

l

Ai

r in

hy

d

raul

ic

s

y

s

tem

Ou

ter/i

n

n

e

r

s

o

ck

et ba

ll joi

n

t swin

gi

ng

to

rqu

e

Ou

ter/i

n

n

e

r

so

cket ba

ll joi

n

t rot

a

tin

g

torq

ue

Ou

ter/i

n

n

e

r

s

o

ck

et ba

ll joi

n

t en

d

p

la

y

S

tee

rin

g

f

lui

d l

e

a

k

a

g

e

S

te

e

ri

ng

whe

e

l pl

ay

S

te

e

ri

ng

ge

ar ra

ck s

lid

in

g f

o

rc

e

Dri

ve b

el

t

lo

os

en

es

s

Im

p

rope

r s

tee

rin

g

wh

ee

l

Im

p

rope

r i

n

s

tal

lat

io

n

o

r lo

os

en

es

s

of

til

t lo

ck

l

e

v

e

r

M

ou

nti

ng

lo

os

en

es

s

S

tee

rin

g

c

o

lu

m

n

d

e

fo

rm

ati

o

n

or

da

ma

ge

Im

p

rope

r i

n

s

tal

lat

io

n

o

r lo

os

en

es

s

of

ste

e

ri

ng

c

o

lu

mn

S

tee

rin

g l

ink

a

ge

lo

os

en

es

s

PROPELLER SHAFT

DIF

F

ERENTIA

L

AX

LE and SUSPE

N

S

ION

TI

RE

ROAD WHE

E

L

DRIVE

SHAFT

BRAK

E

Symptom

Steering

Noise

× × × × × × × × ×

× ×

× × × × × × ×

Shake

× × ×

×

× × × × ×

Vibration

× × × × ×

×

× ×

×

Shimmy

×

×

×

× × ×

×

Judder

× ×

×

× × ×

×

Revision: 2013 February

2012 MURANO