Nissan Murano Z51 (2012 year). Manual - part 48

LU-6

< PREPARATION >

PREPARATION

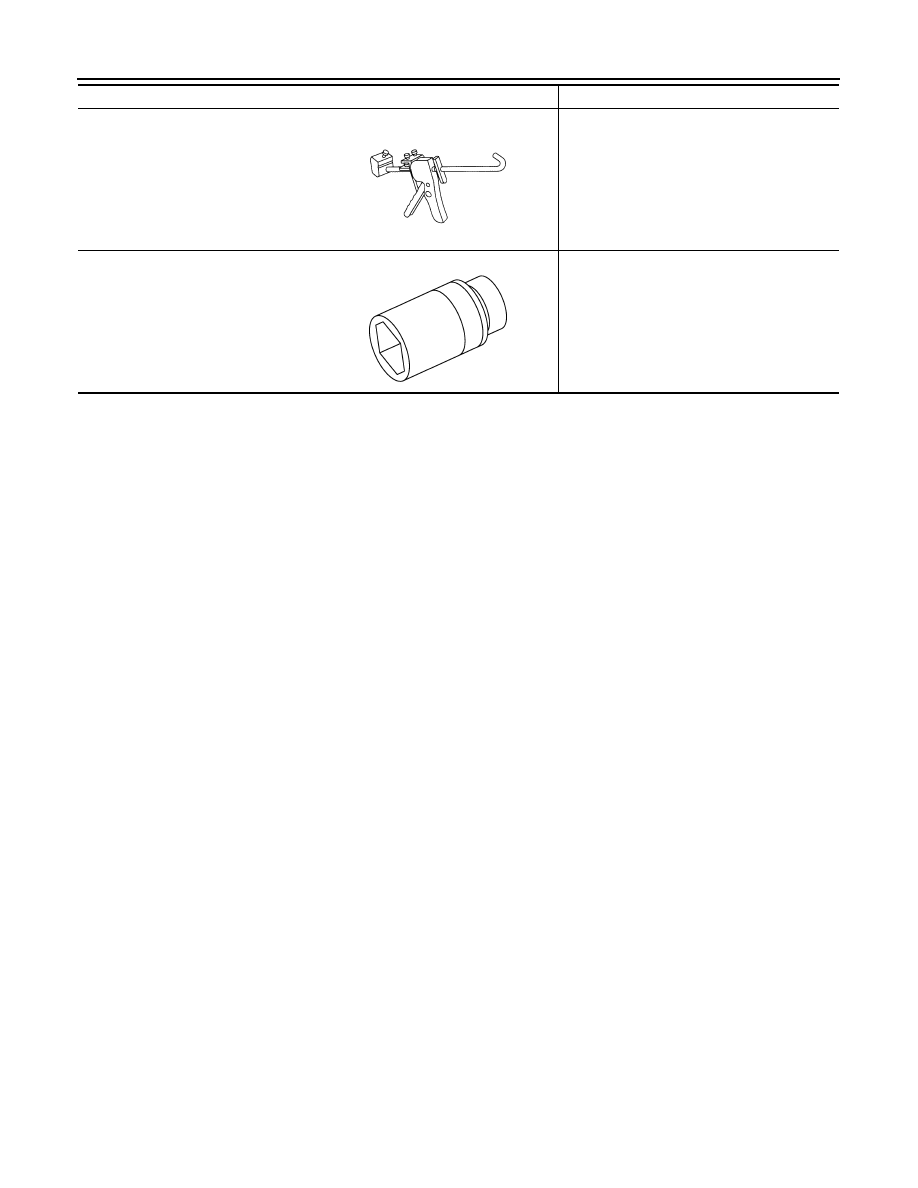

Tube presser

Pressing the tube of liquid gasket

Deep socket

Removing and installing oil pressure switch

27 mm (1.06 in)

Tool name

Description

NT052

PBIC4066E

Revision: 2013 February

2012 MURANO