Nissan Murano Z51 (2012 year). Manual - part 47

LAN

HVAC BRANCH LINE CIRCUIT

LAN-141

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 6)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

HVAC BRANCH LINE CIRCUIT

Diagnosis Procedure

INFOID:0000000007544358

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check the terminals and connectors of the A/C auto amp. for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

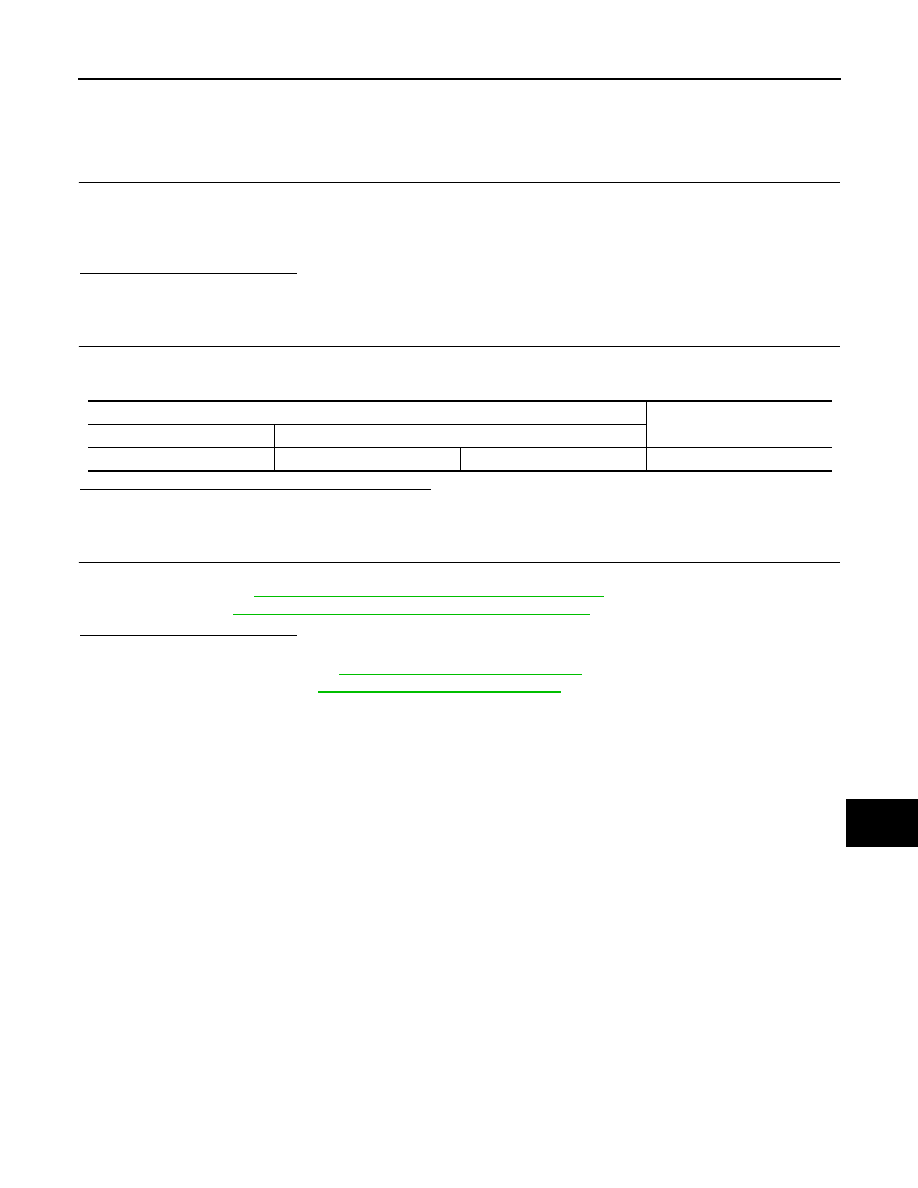

CHECK HARNESS FOR OPEN CIRCUIT

1.

Disconnect the connector of A/C auto amp.

2.

Check the resistance between the A/C auto amp. harness connector terminals.

Is the measurement value within the specification?

YES

>> GO TO 3.

NO

>> Repair the A/C auto amp. branch line.

3.

CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the A/C auto amp. Refer to the following.

• Without 7 inch display:

HAC-77, "A/C AUTO AMP. : Diagnosis Procedure"

• With 7 inch display:

HAC-196, "A/C AUTO AMP. : Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the A/C auto amp. Refer to the following.

• Without 7 inch display:

VTL-24, "Removal and Installation"

• With 7 inch display:

VTL-87, "Removal and Installation"

YES (Past error)>>Error was detected in the A/C auto amp. branch line.

NO

>> Repair the power supply and the ground circuit.

A/C auto amp. harness connector

Resistance (

Ω

)

Connector No.

Terminal No.

M50

1

2

Approx. 54 – 66

Revision: 2013 February

2012 MURANO