Nissan Murano Z51 (2012 year). Manual - part 38

IP-20

< REMOVAL AND INSTALLATION >

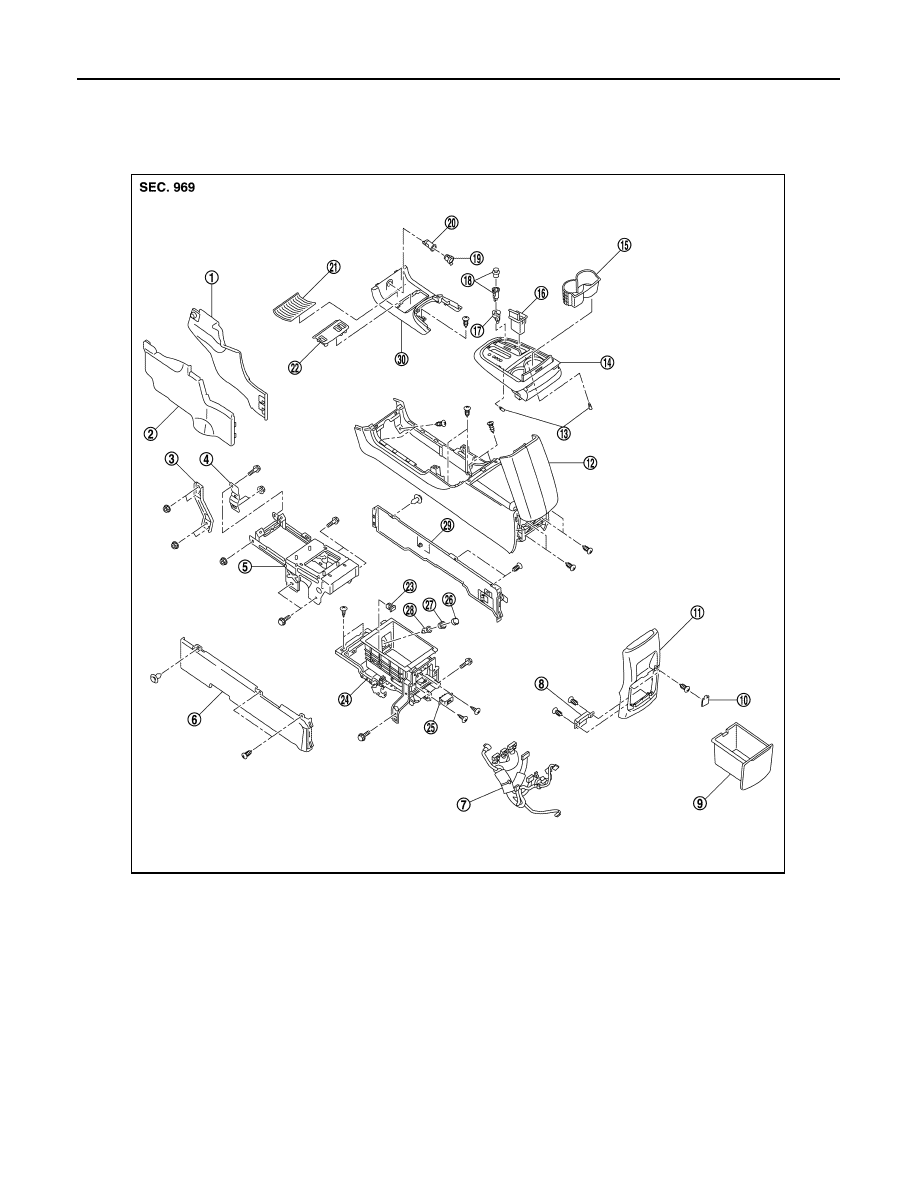

CENTER CONSOLE ASSEMBLY

CENTER CONSOLE ASSEMBLY

Exploded View

INFOID:0000000007542489

1.

Instrument lower cover RH

2.

Instrument lower cover LH

3.

Instrument stay LH

4.

Front console bracket

5.

Console reinforcement

6.

Lower console finisher LH

7.

Console harness

8.

Inside key antenna

9.

Rear console pocket

10. Console mask

11.

Console rear finisher

12. Center console assembly

13. Socket and bulb

14. Console finisher assembly

15. Cup holder assembly

16. Ashtray

17. Cigarette lighter ring

18. Cigarette lighter complete

19. Socket knob

20. Socket inner case

21. Console mat

22. Console switch finisher

23. USB connector

24. Lower console assembly

25. Auxiliary input jacks

26. Socket knob

27. Socket ring

28. Socket inner case

29. Lower console finisher RH

30. Front console pocket

JMJIA4761ZZ

Revision: 2013 February

2012 MURANO