Nissan Murano Z51 (2011 year). Manual - part 14

C1144 INCOMPLETE STEERING ANGLE SENSOR ADJUSTMENT

BRC-71

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1144 INCOMPLETE STEERING ANGLE SENSOR ADJUSTMENT

Description

INFOID:0000000006263462

The steering angle sensor detects the rotation amount, angular velocity and direction of the steering wheel,

and transmits the data to the ABS actuator and electric unit (control unit) via CAN communication.

DTC Logic

INFOID:0000000006263463

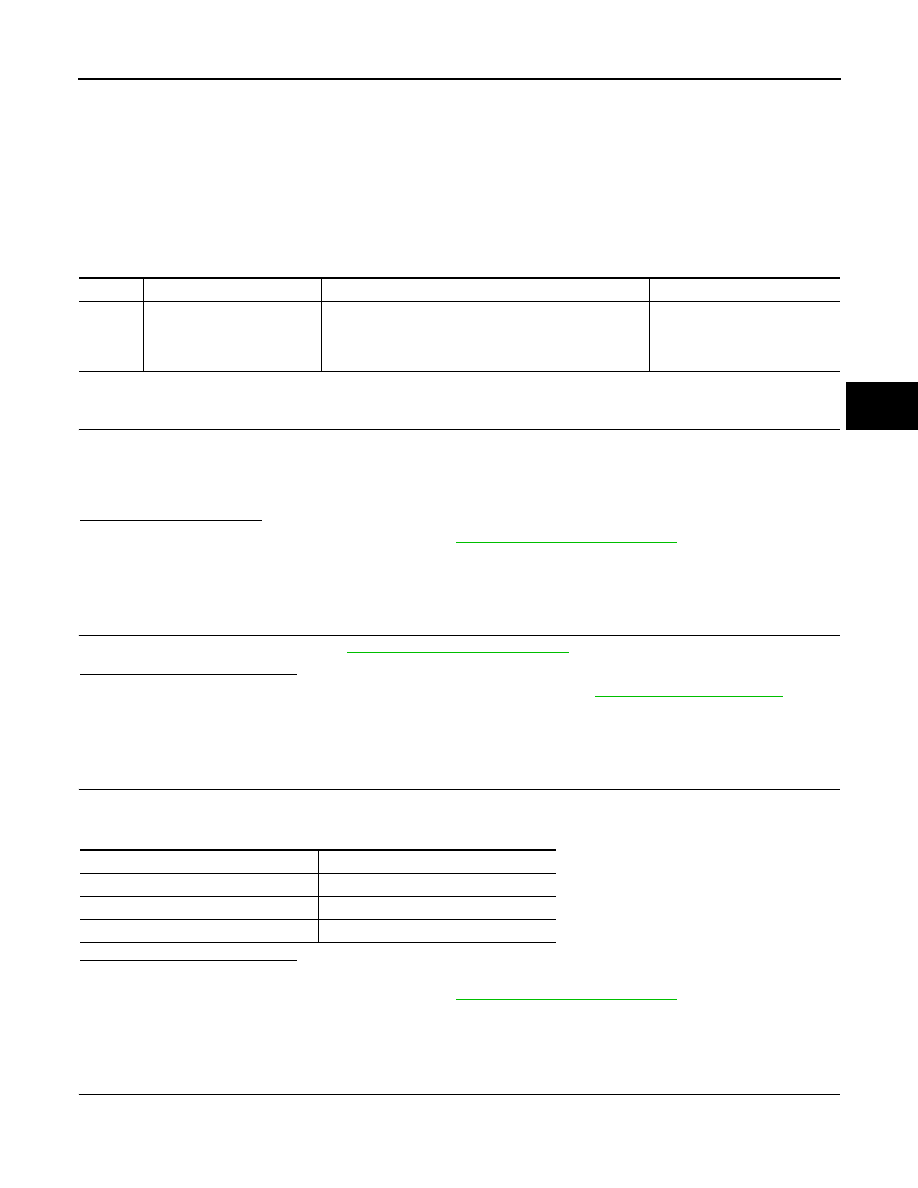

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

DTC REPRODUCTION PROCEDURE

1.

Turn the ignition switch ON.

2.

Select “ABS”, “WORK SUPPORT” and “ST ANGLE SENSOR ADJUSTMENT” in order with CONSULT-III,

and perform adjust the neutral position of steering angle sensor.

3.

Perform self-diagnosis for “ABS” with CONSULT-III.

Is DTC “C1144” detected?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000006263464

1.

CHECK STEERING ANGLE SENSOR

Check steering angle sensor. Refer to

Is the inspection result normal?

YES

>> Replace ABS actuator and electric unit (control unit). Refer to

NO

>> Repair or replace error-detected parts.

Component Inspection

INFOID:0000000006263465

1.

CHECK DATA MONITOR

Select “ABS”, “DATA MONITOR” and “STR ANGLE SIG” in order with CONSULT-III, and check steering angle

sensor signal.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to diagnosis procedure. Refer to

.

Special Repair Requirement

INFOID:0000000006263466

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION AND CALIBRATION OF DECEL G

SENSOR

• After removing/replacing a steering angle sensor, be sure to perform the following procedure.

DTC

Display item

Malfunction detected condition

Possible cause

C1144

ST ANG SEN SIGNAL

Adjustment of steering angle sensor neutral position is

not finished.

• Harness or connector

• Steering angle sensor

• ABS actuator and electric unit

(control unit)

Steering condition

STR ANGLE SIG (DATA MONITOR)

Driving straight

−

3.5 – +3.5

°

Turn 90

°

to right

Approx.

−

90

°

Turn 90

°

to left

Approx. +90

°

Revision: 2011 November

2011 MURANO