Nissan Murano Z50 (2007 year). Manual - part 191

SERVICE DATA AND SPECIFICATIONS (SDS)

TF-71

C

E

F

G

H

I

J

K

L

M

A

B

TF

Revision: 2006 July

2007 Murano

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

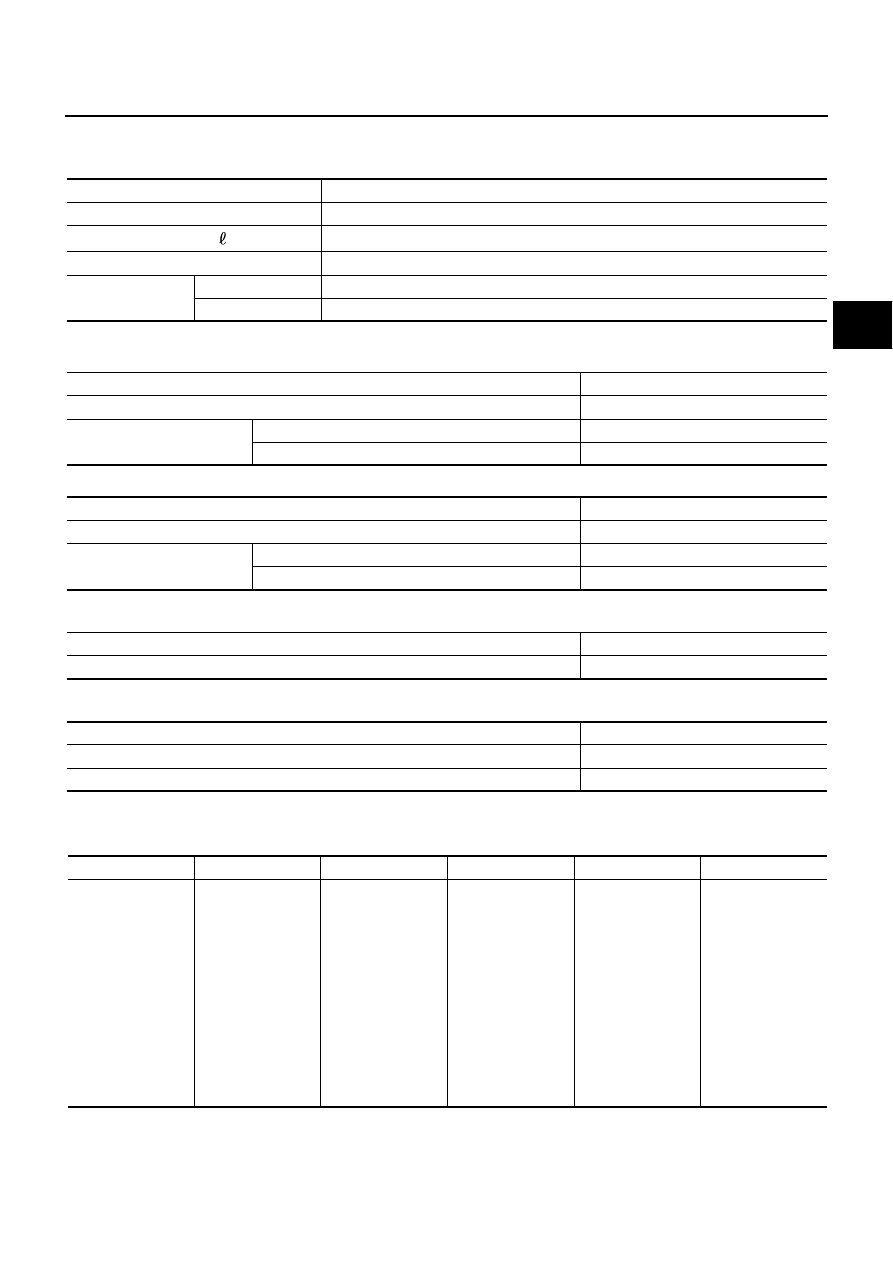

General Specifications

NDS00082

Inspection and Adjustment

NDS00083

PRELOAD TORQUE BEFORE DISASSEMBLY

PRELOAD TORQUE AFTER DISASSEMBLY AND REASSEMBLY

BACKLASH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in)

SELECTIVE PARTS

Gear Ring Bearing Adjusting Shim (Transfer Case Side)

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Applied model

VQ35DE

Transfer model

TY20A

Oil capacity (Approx.)

(US pt, lmp pt)

0.31 (5/8, 1/2)

Gear ratio

0.404

Number of teeth

Drive pinion

17

Drive gear

42

Item

Specification [N·m (kg-m, in-lb)]

Pinion bearing (P

1

)

0.10 - 0.39 (0.01 - 0.04, 1 - 3)

Gear ring bearing to pinion

bearing (Total preload)

With all oil seals

P

1

+ 0.16 - 0.22 (0.016 - 0.023, 1.4 - 1.9)

Without transfer case oil seal and adapter case oil seal

P

1

+ 0.06 - 0.12 (0.006 - 0.013, 0.6 - 1.1)

Item

Specification [N·m (kg-m, in-lb)]

Pinion bearing (P’

1

)

0.40 - 0.78 (0.04 - 0.08, 4 - 6)

Gear ring bearing to pinion

bearing (Total preload)

With all oil seals

P’

1

+ 0.45 - 0.47 (0.045 - 0.048, 3.9 - 4.1)

Without transfer case oil seal and adapter case oil seal

P’

1

+ 0.35 - 0.37 (0.035 - 0.038, 3.1 - 3.2)

Item

Standard

Drive gear to drive pinion gear

0.13 - 0.19 (0.0051 - 0.0075)

Item

Runout limit

Companion flange face

0.1 (0.004)

Inner side of the companion flange

0.1 (0.004)

Thickness Part

number*

Thickness Part

number*

Thickness Part

number*

0.80 (0.0315)

0.83 (0.0327)

0.86 (0.0339)

0.89 (0.0350)

0.92 (0.0362)

0.95 (0.0374)

0.98 (0.0386)

1.01 (0.0398)

1.04 (0.0409)

1.07 (0.0421)

1.10 (0.0433)

1.13 (0.0445)

1.16 (0.0457)

1.19 (0.0469)

33147 AD300

33147 AD301

33147 AD302

33147 AD303

33147 AD304

33147 AD305

33147 AD306

33147 AD307

33147 AD308

33147 AD309

33147 AD310

33147 AD311

33147 AD312

33147 AD313

1.22 (0.0480)

1.25 (0.0492)

1.28 (0.0504)

1.31 (0.0516)

1.34 (0.0528)

1.37 (0.0539)

1.40 (0.0551)

1.43 (0.0563)

1.46 (0.0575)

1.49 (0.0587)

1.52 (0.0598)

1.55 (0.0610)

1.58 (0.0622)

1.61 (0.0634)

33147 AD314

33147 AD315

33147 AD316

33147 AD317

33147 AD318

33147 AD319

33147 AD320

33147 AD321

33147 AD322

33147 AD323

33147 AD324

33147 AD360

33147 AD361

33147 AD362

1.64 (0.0646)

1.67 (0.0657)

1.70 (0.0669)

1.73 (0.0681)

1.76 (0.0693)

1.79 (0.0705)

1.82 (0.0717)

1.85 (0.0728)

1.88 (0.0740)

1.91 (0.0752)

1.94 (0.0764)

1.97 (0.0776)

2.00 (0.0787)

2.03 (0.0799)

33147 AD363

33147 AD364

33147 AD365

33147 AD366

33147 AD367

33147 AD368

33147 AD369

33147 AD370

33147 AD371

33147 AD372

33147 AD373

33147 AD374

33147 AD375

33147 AD376