Nissan Murano Z50 (2007 year). Manual - part 186

CRASH ZONE SENSOR

SRS-51

C

D

E

F

G

I

J

K

L

M

A

B

SRS

Revision: 2006 July

2007 Murano

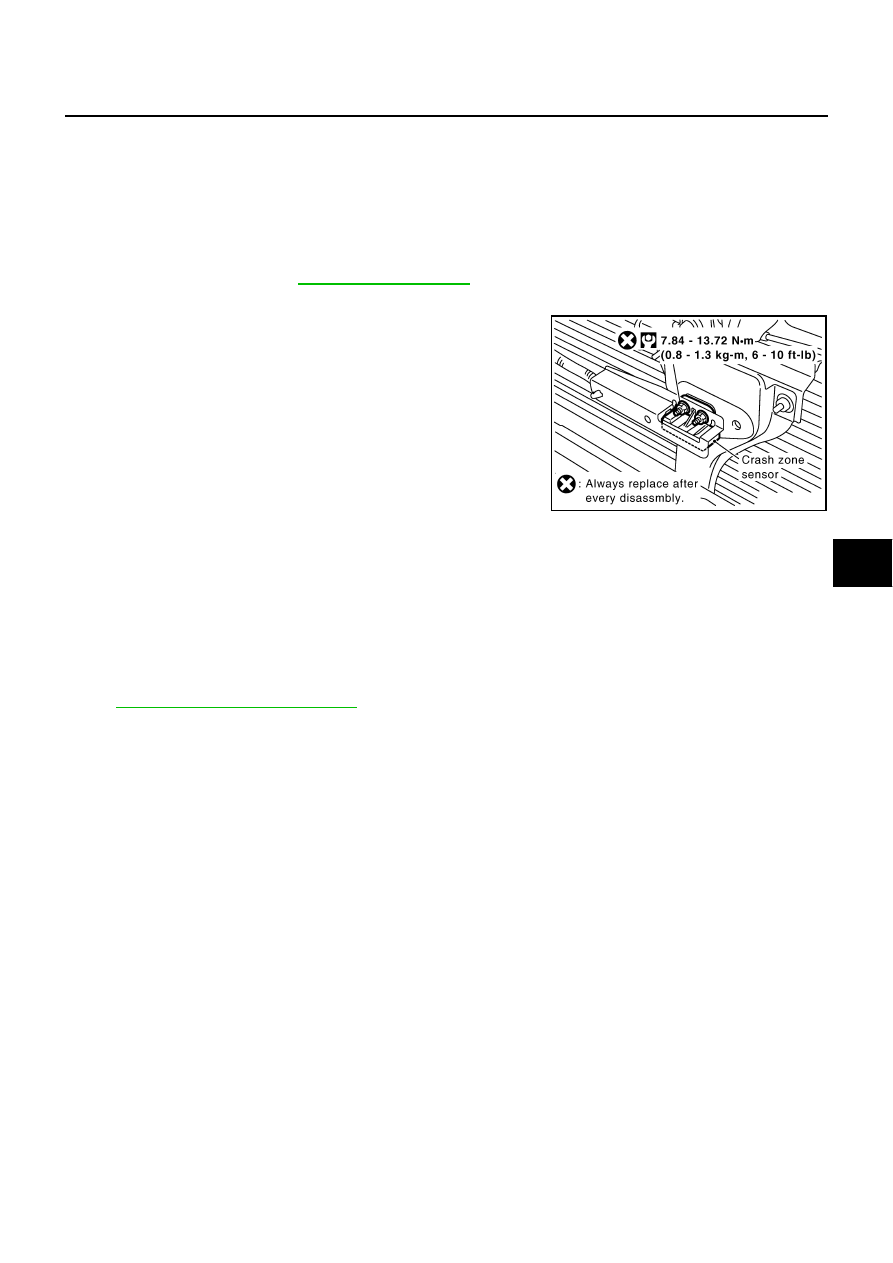

CRASH ZONE SENSOR

PFP:98531

Removal and Installation

NHS0005U

REMOVAL

CAUTION:

●

Before servicing SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3

minutes.

●

Do not use air tools or electric tools for servicing.

1.

Remove front grille. Refer to

2.

Remove crash zone sensor connector.

3.

Remove crash zone sensor fixing nuts.

CAUTION:

●

Replace crash zone sensor if it has been dropped or sustained an impact.

●

Do not disassemble crash zone sensor.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

●

Check crash zone sensor for proper installation.

●

After the work is complete, perform self-diagnosis to make sure no malfunction is detected. Refer

to

.

PHIA0259E