Nissan Murano Z50 (2007 year). Manual - part 166

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

M

A

B

SC

Revision: 2006 July

2007 Murano

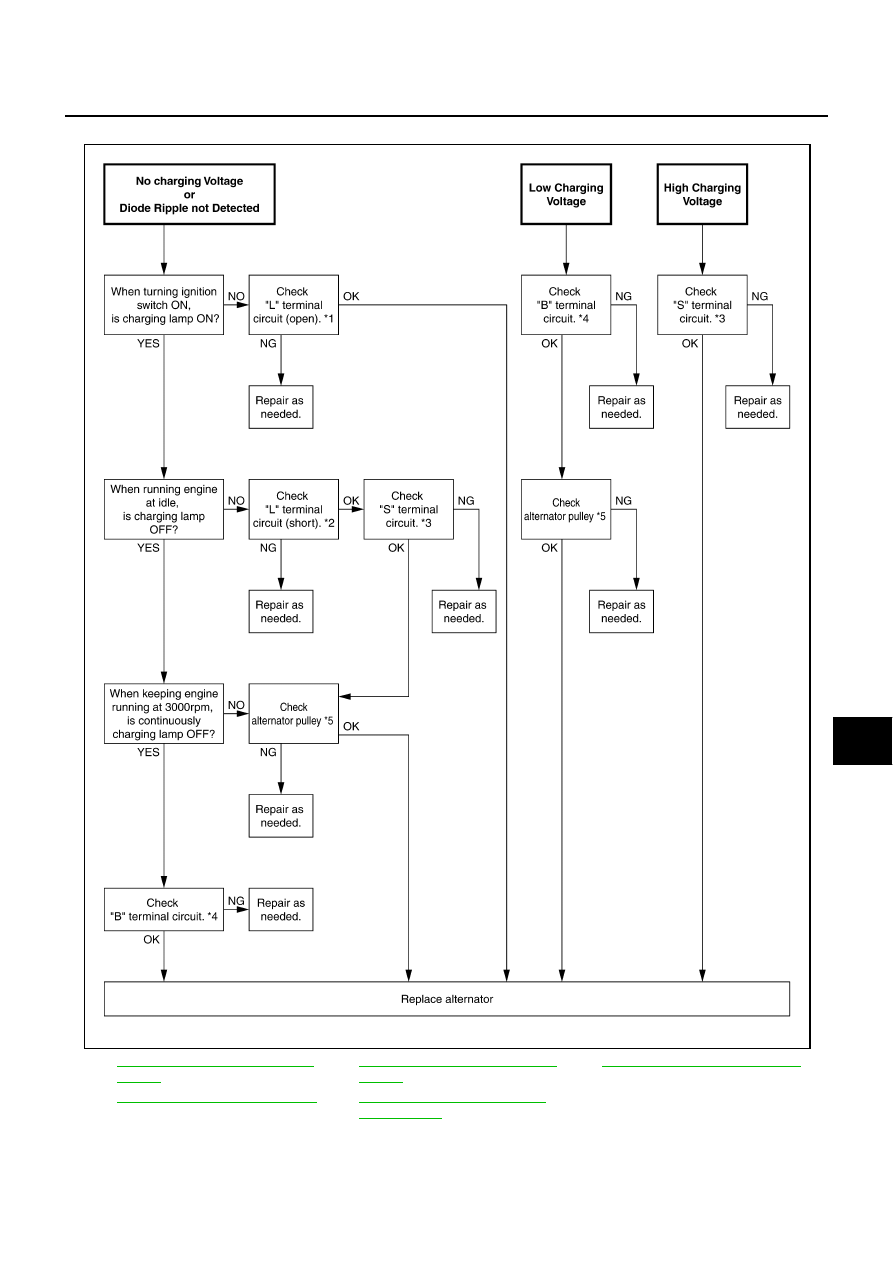

WORK FLOW

*1

SC-23, "Check “L” Terminal Circuit

(Open)"

*2

SC-23, "Check “L” Terminal Circuit

(Short)"

*3

SC-24, "Check “S” Terminal Circuit"

*4

SC-25, "Check “B” Terminal Circuit"

*5

SC-27, "ALTERNATOR PULLEY

INSPECTION"

SKIB0527E