Nissan Murano Z50 (2007 year). Manual - part 161

PREPARATION

RFD-5

C

E

F

G

H

I

J

K

L

M

A

B

RFD

Revision: 2006 July

2007 Murano

Commercial Service Tools

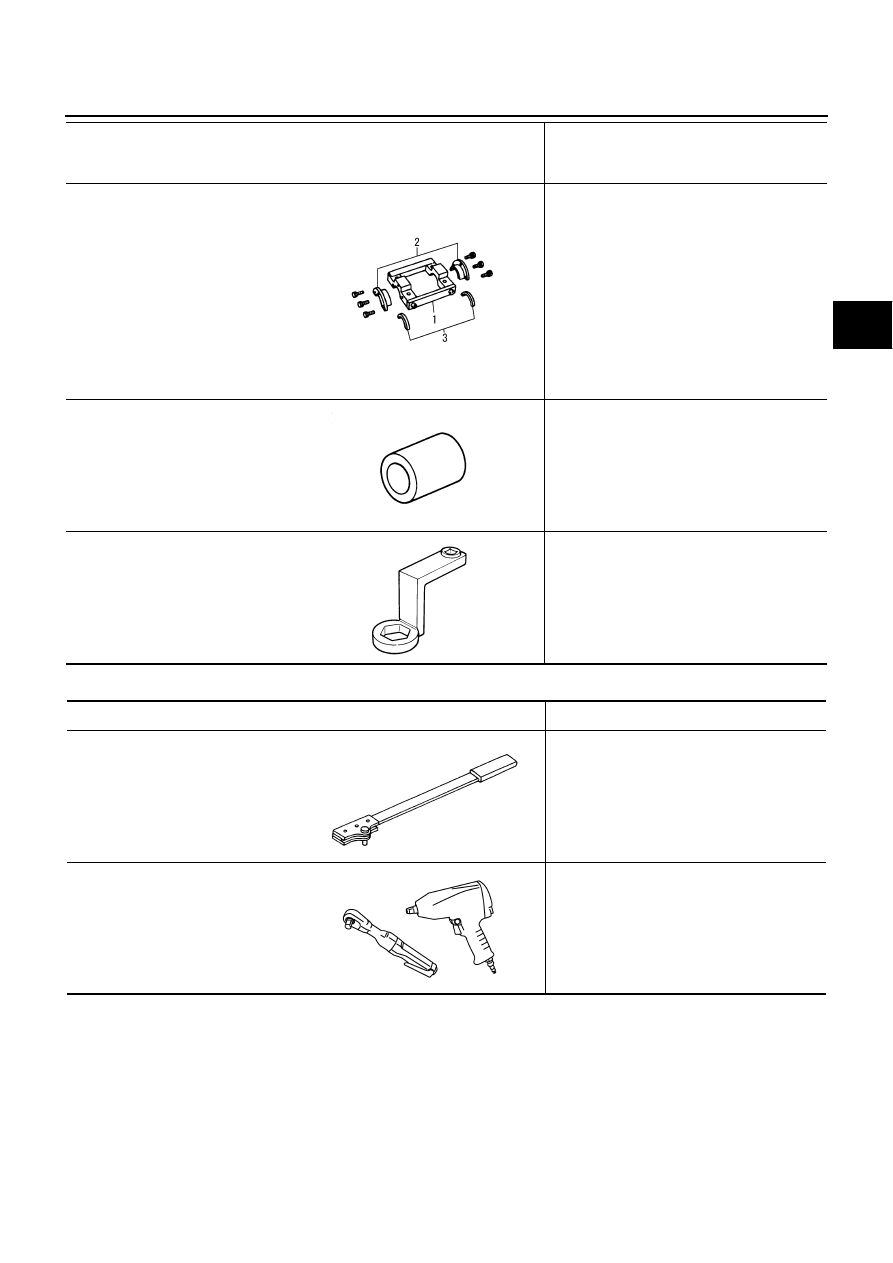

NDS0008D

KV381086S1

(

—

)

Dummy cover set

1. KV38108610

(

—

)

Dummy cover

2. KV38108621

(

—

)

Dummy cover spacer

3. KV38108630

(

—

)

Dummy cover shim

●

Checking backlash

●

Checking drive gear runout

●

Checking tooth contact

KV38108500

(

—

)

Drive pinion socket

●

Measuring preload torque

●

Removing and installing drive pinion nut

KV38108400

(

—

)

Pinion nut wrench

●

Measuring preload torque

●

Removing drive pinion nut

Tool number

(Kent-Moore No.)

Tool name

Description

SDIA2313E

ZZA1205D

ZZA1206D

Tool name

Description

Flange wrench

Removing and installing companion flange

lock nut

Power tool

Loosening nuts and bolts

NT771

PBIC0190E