Nissan Murano Z50 (2007 year). Manual - part 146

PREPARATION

LU-3

C

D

E

F

G

H

I

J

K

L

M

A

LU

Revision: 2006 July

2007 Murano

PREPARATION

PFP:00002

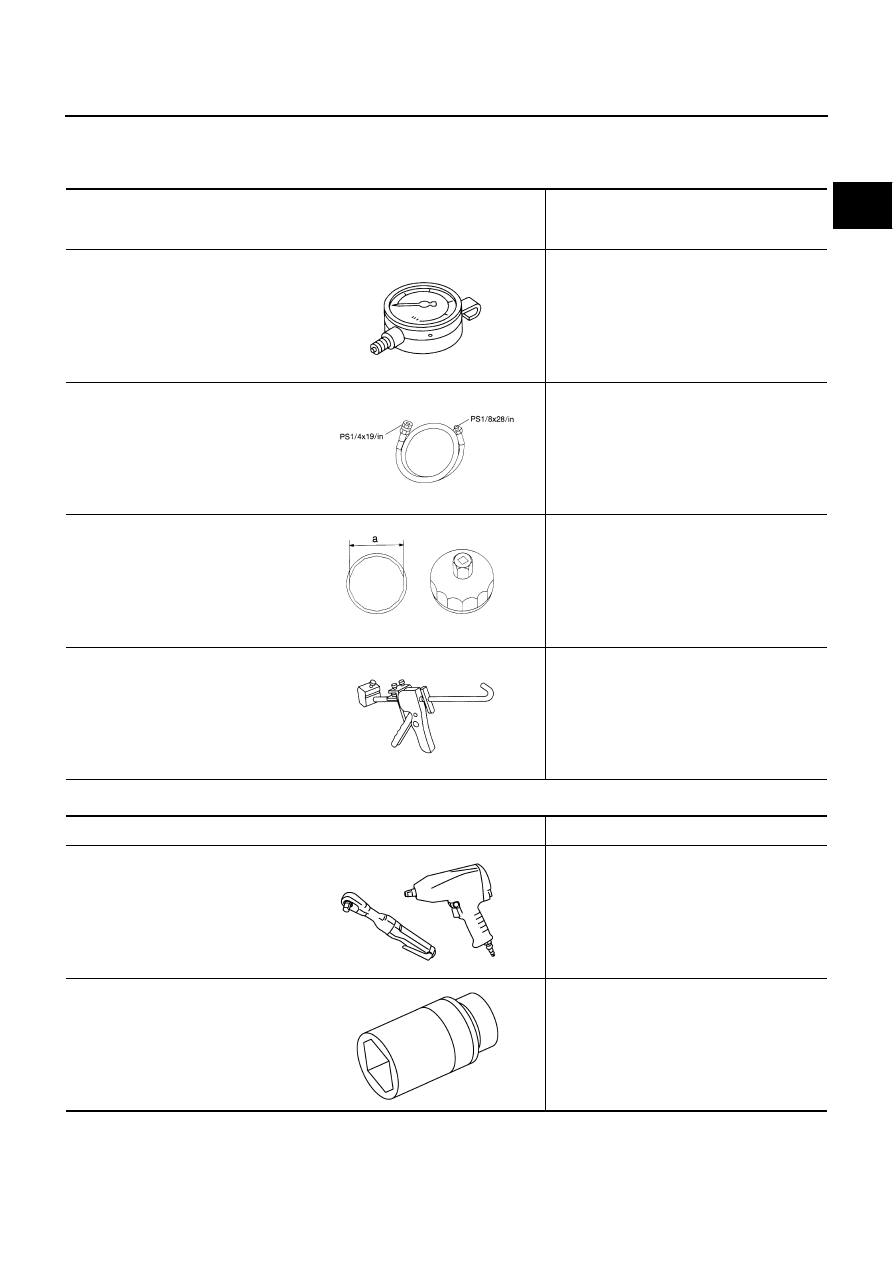

Special Service Tools

NBS002A2

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tools

NBS002A3

Tool number

(Kent-Moore No.)

Tool name

Description

ST25051001

(J25695-1)

Oil pressure gauge

Measuring oil pressure

Maximum measuring range: 2,452 kPa (25

kg/cm

2

, 356 psi)

ST25052000

(J25695-2)

Hose

Adapting oil pressure gauge to oil pan (upper)

KV10115801

(J38956)

Oil filter wrench

Removing oil filter

a: 64.3 mm (2.531 in)

WS39930000

(

—

)

Tube presser

Pressing the tube of liquid gasket

NT050

S-NT559

S-NT375

NT052

Tool name

Description

Power tools

Loosening nuts and bolts

Deep socket

Removing and installing oil pressure switch

a: 27 mm (1.06 in)

PBIC0190E

PBIC4066E