Nissan Murano Z50 (2007 year). Manual - part 130

TROUBLE DIAGNOSIS

LAN-77

[CAN]

C

D

E

F

G

H

I

J

L

M

A

B

LAN

Revision: 2006 July

2007 Murano

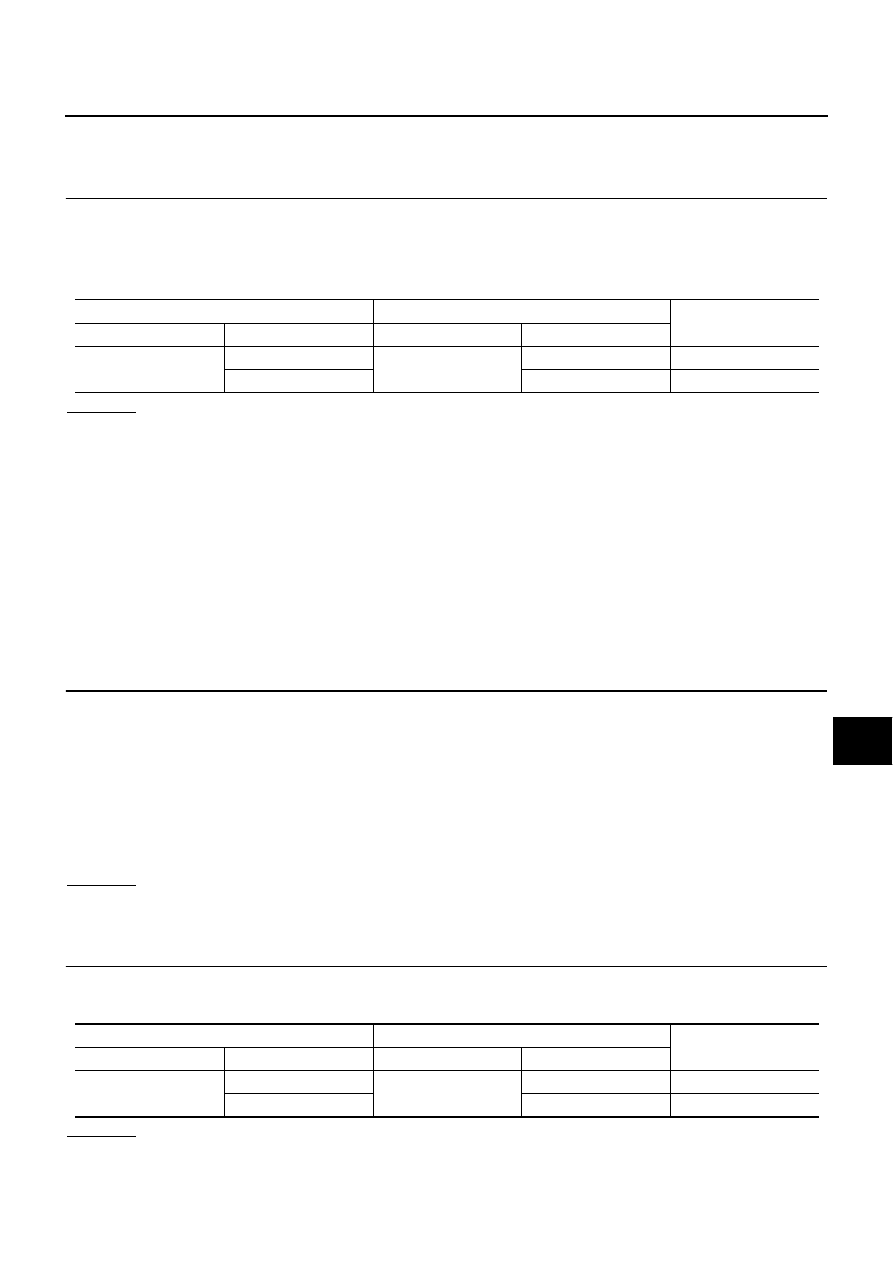

Main Line Between BCM and Data Link Connector

NKS004LH

INSPECTION PROCEDURE

1.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Disconnect ECM connector and BCM connector.

4.

Check the continuity between the BCM harness connector and the data link connector.

OK or NG

OK

>>

●

Present error: Check the following items again.

–

Decision of CAN system type.

–

Not received CONSULT-II data (SELECT SYSTEM, SELF-DIAG RESULTS, CAN DIAG SUP-

PORT MNTR).

–

Not copied from on-board diagnosis.

–

Procedure for detecting root cause.

●

Past error: Error was detected in the main line between the BCM and the data link connector.

NG

>> Repair the main line between the BCM and the data link connector.

Main Line Between Data Link Connector and ABS Actuator and Electric Unit

(Control Unit)

NKS004M2

INSPECTION PROCEDURE

1.

CHECK CONNECTOR

1.

Turn the ignition switch OFF.

2.

Disconnect the battery cable from the negative terminal.

3.

Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

–

Harness connector M9

–

Harness connector B2

–

Harness connector B4

–

Harness connector E105

OK or NG

OK

>> GO TO 2.

NG

>> Repair the terminal and connector.

2.

CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1.

Disconnect the harness connectors M9 and B2.

2.

Check the continuity between the data link connector and the harness connector.

OK or NG

OK

>> GO TO 3.

NG

>> Repair the main line between the data link connector and the harness connector M9.

BCM harness connector

Data link connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M34

39

M24

6

Yes

40

14

Yes

Data link connector

Harness connector

Continuity

Connector No.

Terminal No.

Connector No.

Terminal No.

M24

6

M9

1

Yes

14

13

Yes