Nissan Murano Z50 (2007 year). Manual - part 89

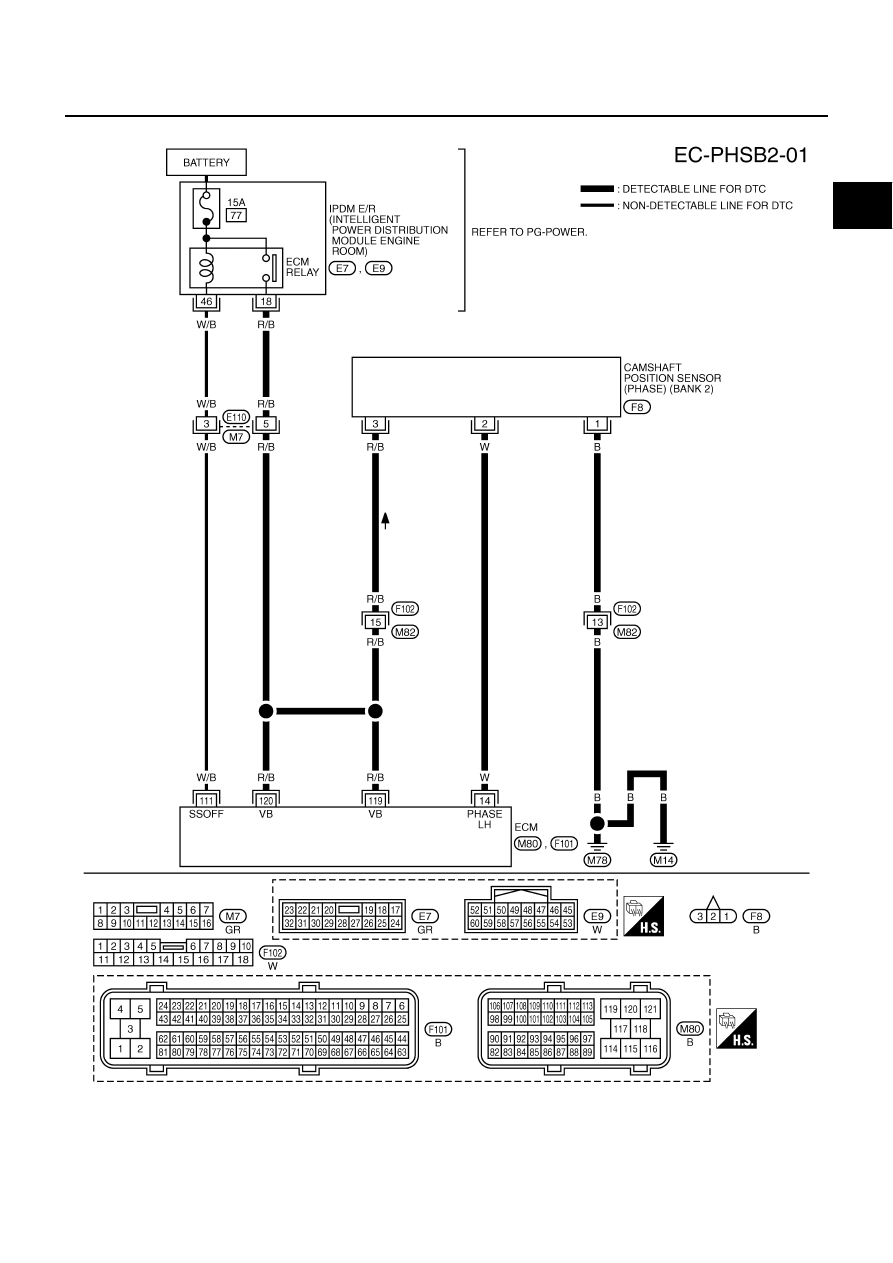

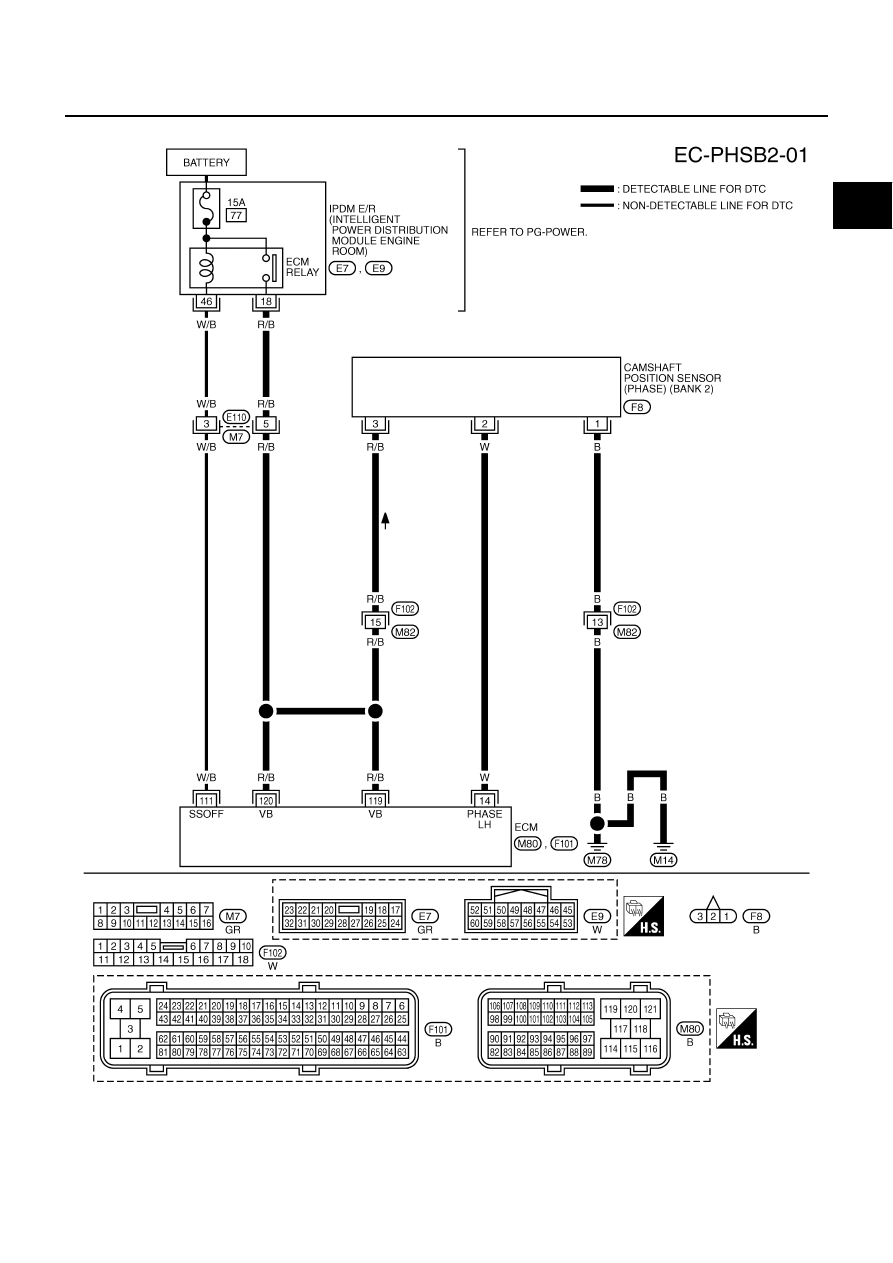

DTC P0340, P0345 CMP SENSOR (PHASE)

EC-373

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 July

2007 Murano

BANK 2

TBWB0803E

|

|

|

DTC P0340, P0345 CMP SENSOR (PHASE) EC-373 C D E F G H I J K L M A EC Revision: 2006 July 2007 Murano BANK 2 TBWB0803E |