Nissan Murano Z50 (2007 year). Manual - part 85

DTC P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

EC-309

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 July

2007 Murano

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

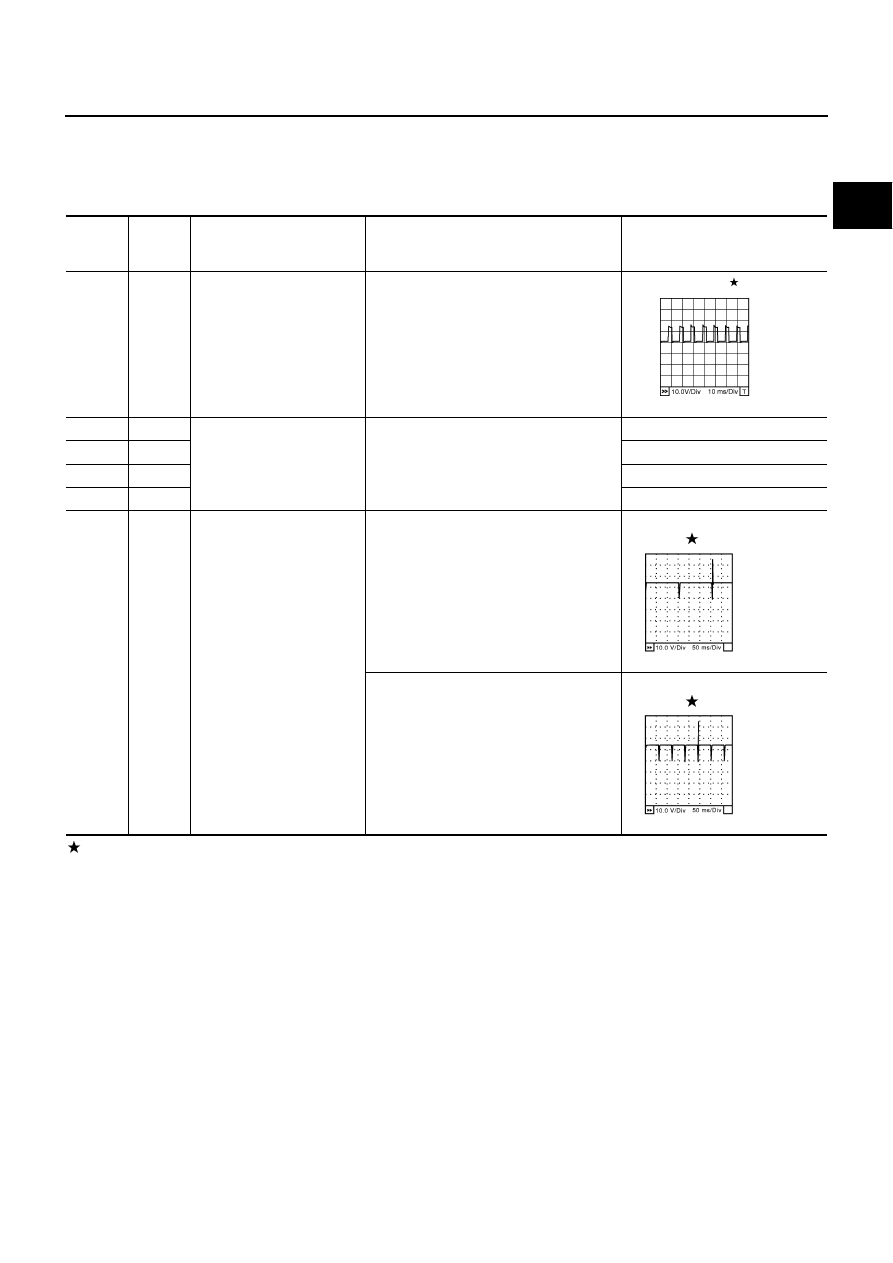

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

TERMI-

NAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

2

G/B

A/F sensor 1 heater

(Bank 1)

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 5V

16

LG/B

A/F sensor 1 (Bank 1)

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 3.1V

35

O/L

Approximately 2.6V

56

BR/Y

Approximately 2.3V

75

Y/R

Approximately 2.3V

21

22

23

L/W

R/Y

R/B

Fuel injector No. 5

Fuel injector No. 3

Fuel injector No. 1

[Engine is running]

●

Warm-up condition

●

Idle speed

NOTE:

The pulse cycle changes depending on

rpm at idle.

BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

●

Warm-up condition

●

Engine speed: 2,000 rpm

BATTERY VOLTAGE

(11 - 14V)

PBIB1584E

SEC984C

SEC985C