Nissan Murano Z50 (2007 year). Manual - part 67

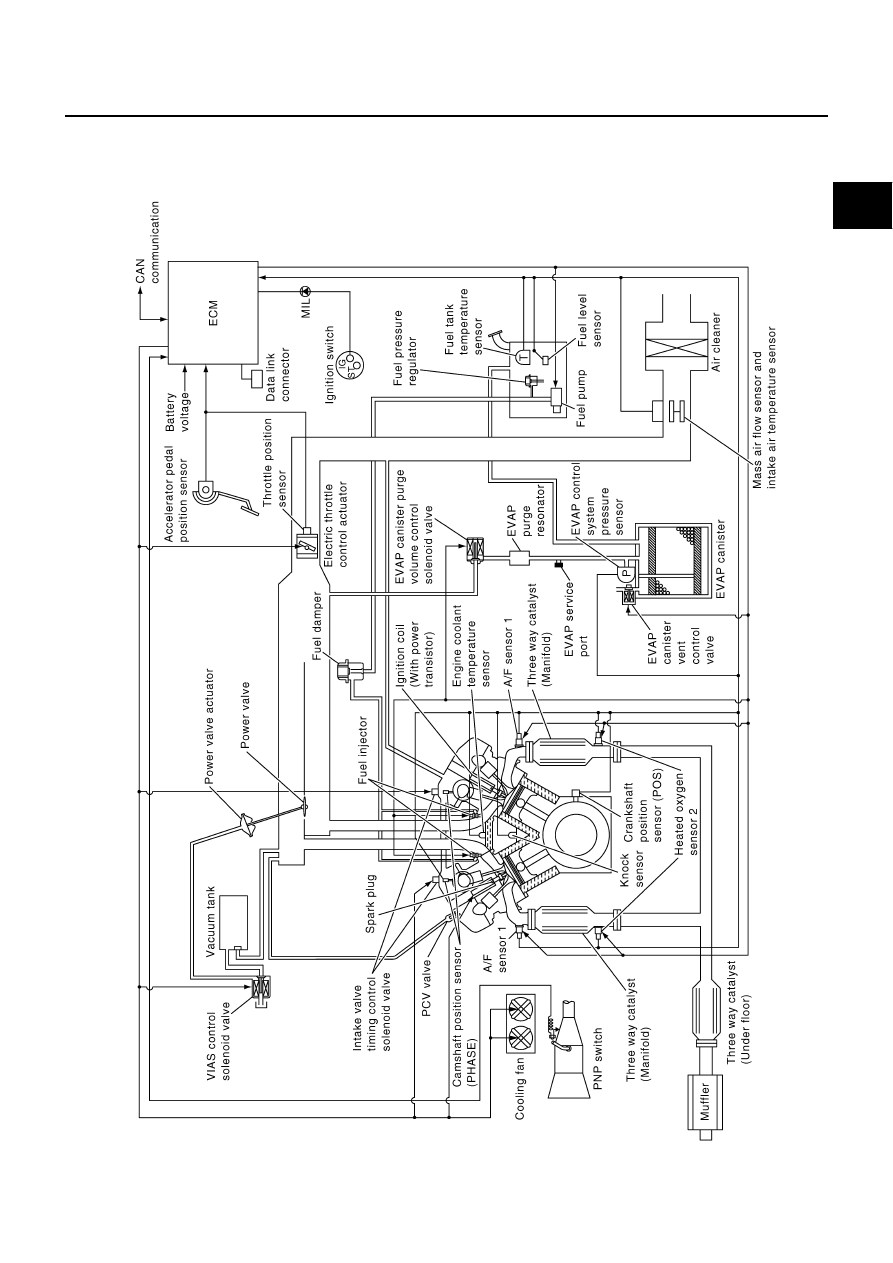

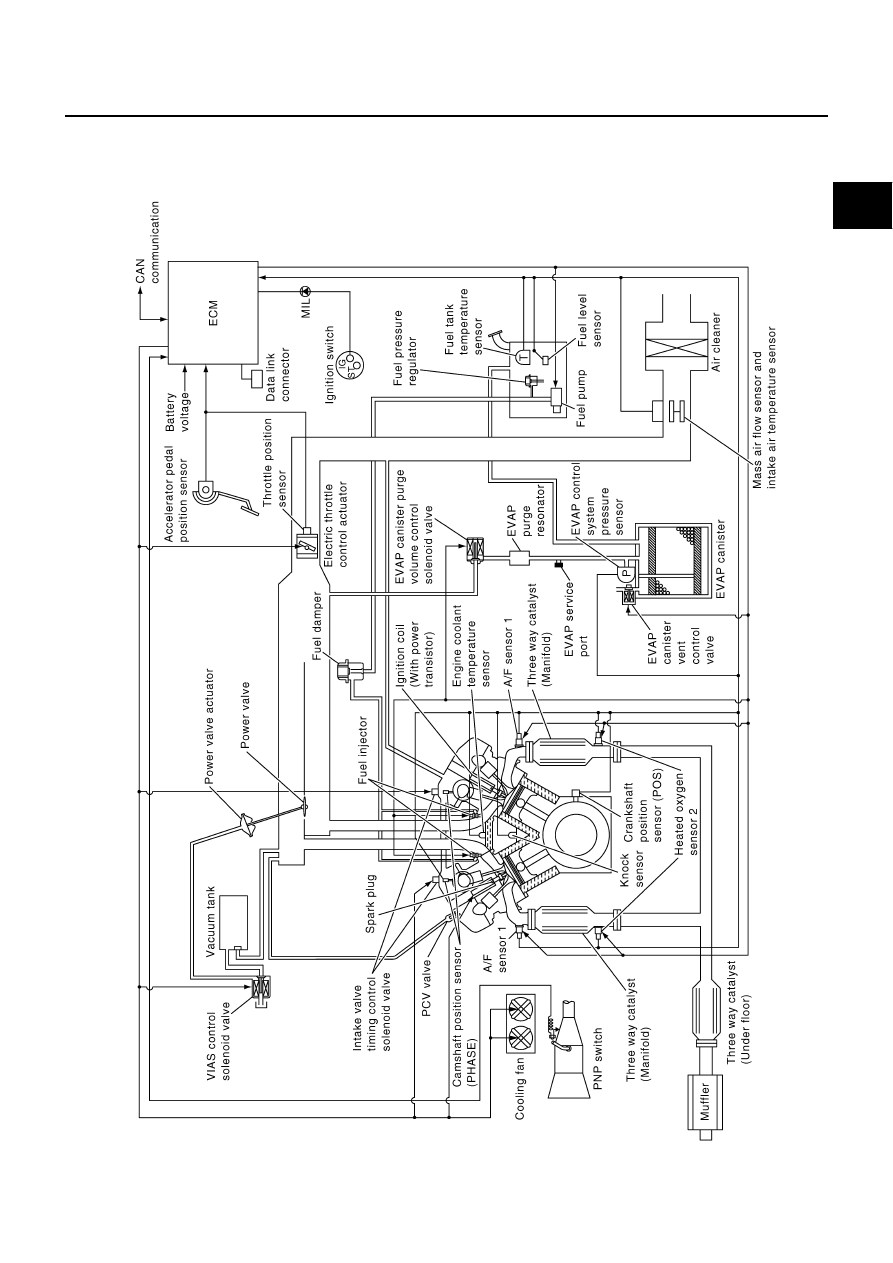

ENGINE CONTROL SYSTEM

EC-21

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 July

2007 Murano

ENGINE CONTROL SYSTEM

PFP:23710

System Diagram

NBS002YI

PBIB2307E

|

|

|

ENGINE CONTROL SYSTEM EC-21 C D E F G H I J K L M A EC Revision: 2006 July 2007 Murano ENGINE CONTROL SYSTEM PFP:23710 System Diagram NBS002YI PBIB2307E |