Nissan Murano Z50 (2007 year). Manual - part 40

TROUBLE DIAGNOSIS FOR SYSTEM

BRC-35

[ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

Revision: 2006 July

2007 Murano

2.

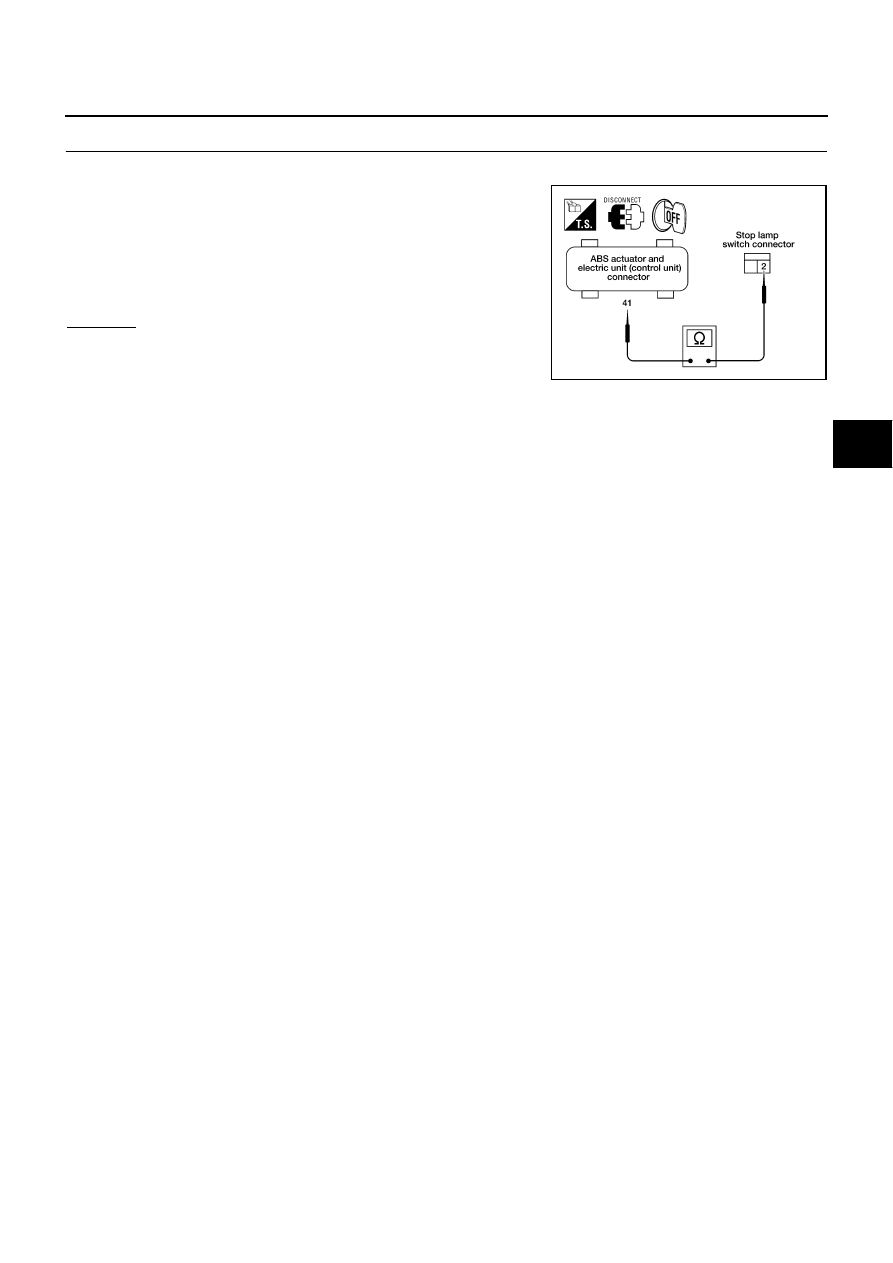

CHECK STOP LAMP SWITCH CIRCUIT

1.

Turn ignition switch “OFF”.

2.

Disconnect stop lamp switch connector E116 and ABS actuator

and electric unit (control unit) connector E24.

3.

Check continuity between stop lamp switch harness connector

E116 and ABS actuator and electric unit (control unit) harness

connector E24.

OK or NG

OK

>> Connect connectors and perform an ABS actuator and

electric unit (control unit) self-diagnosis.

NG

>> Open or short in harness. Repair or replace harness.

41 - 2

: Continuity should exist.

LFIA0150E