Nissan Murano Z50 (2007 year). Manual - part 32

INTEGRATED HOMELINK TRANSMITTER

BL-257

C

D

E

F

G

H

J

K

L

M

A

B

BL

Revision: 2006 July

2007 Murano

Trouble Diagnoses

NIS001AA

DIAGNOSTIC PROCEDURE

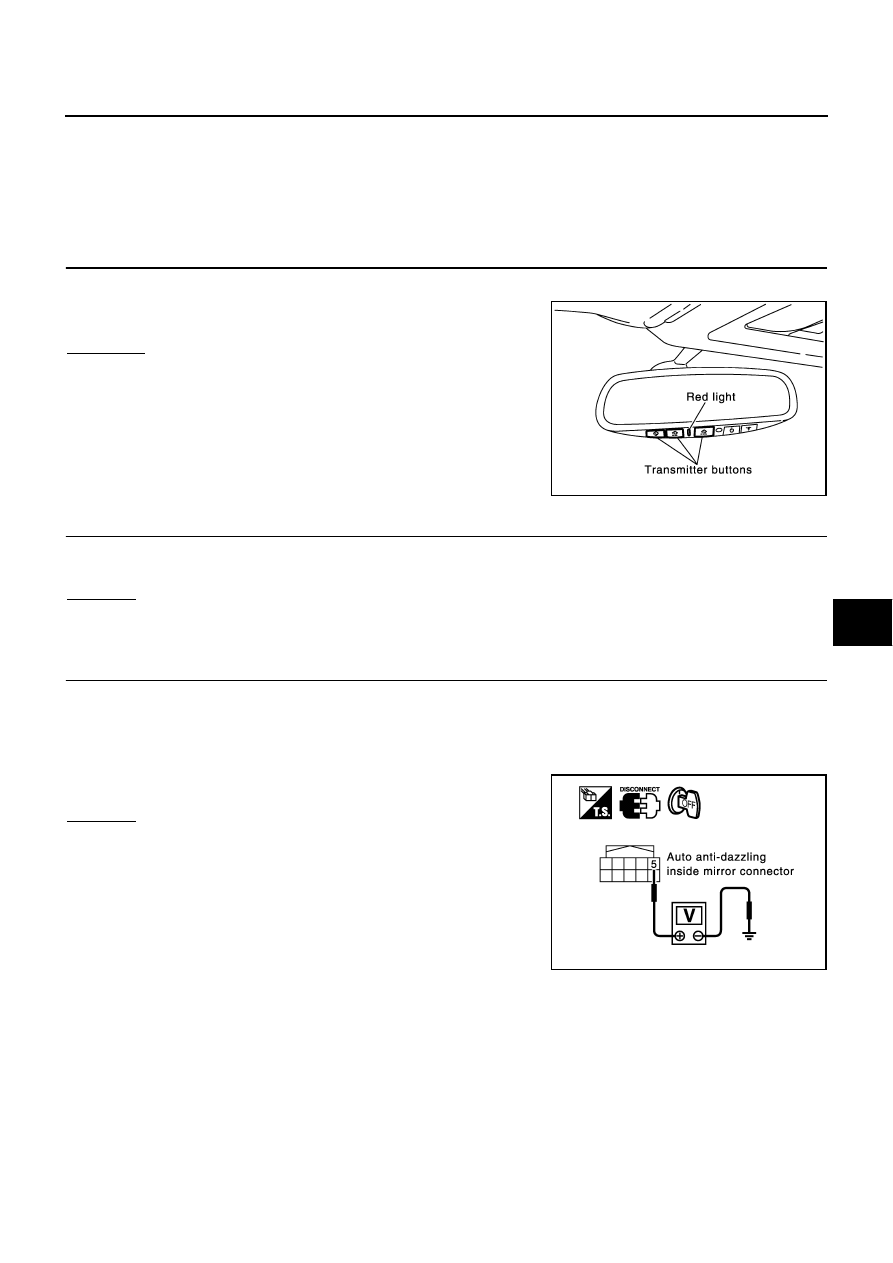

SYMPTOM: Transmitter Does Not Activate Receiver

Before conducting the procedure given below, make sure that system receiver (garage door opener, etc.)

operates with original, hand-held transmitter. If NG, receiver or hand-held transmitter is malfunctioning, not

vehicle related.

1.

CHECK ILLUMINATION

1.

Turn ignition switch “OFF”.

2.

Does red light (LED) of transmitter illuminate when any transmit-

ter button is pressed?

YES or NO

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK TRANSMITTER

Check auto anti-dazzling inside mirror (homelink universal transceiver) with Tool*.

*:For details, refer to Technical Service Bulletin.

OK or NG

OK

>> Receiver or hand-held transmitter malfunction, not vehicle related.

NG

>> Replace inside mirror assembly.

3.

CHECK POWER SUPPLY

1.

Disconnect auto anti-dazzling inside mirror (homelink universal transceiver) connector.

2.

Turn ignition switch “OFF”.

3.

Check voltage between auto anti-dazzling inside mirror (homelink universal transceiver) connector R4 ter-

minal 5 (Y) and ground.

OK or NG

OK

>> GO TO 4.

NG

>>

●

Check 10A fuse. [No. 19 located in the fuse block (J/

B)]

●

Repair or replace harness between fuse and anti-daz-

zling inside mirror (homelink universal transceiver).

PIIA4815E

5 (Y) – Ground

: Battery voltage

PIIA2370E