Nissan Murano Z50 (2006 year). Manual - part 181

POWER STEERING OIL PUMP

PS-31

C

D

E

F

H

I

J

K

L

M

A

B

PS

Revision: 2006 August

2006 Murano

DISASSEMBLY

NOTE:

Secure oil pump in a vise if necessary.

CAUTION:

When retaining drive shaft in a vise, always use copper or aluminum plates between vise and shaft.

1.

Remove rear cover mounting bolts and then remove rear cover from body assembly.

2.

Remove gasket from body assembly.

3.

Remove dowel pin, cartridge and side plate from body assembly.

4.

Remove pulley mounting nut and then remove pulley from drive shaft.

5.

Remove bracket mounting bolts and then remove bracket from body assembly.

6.

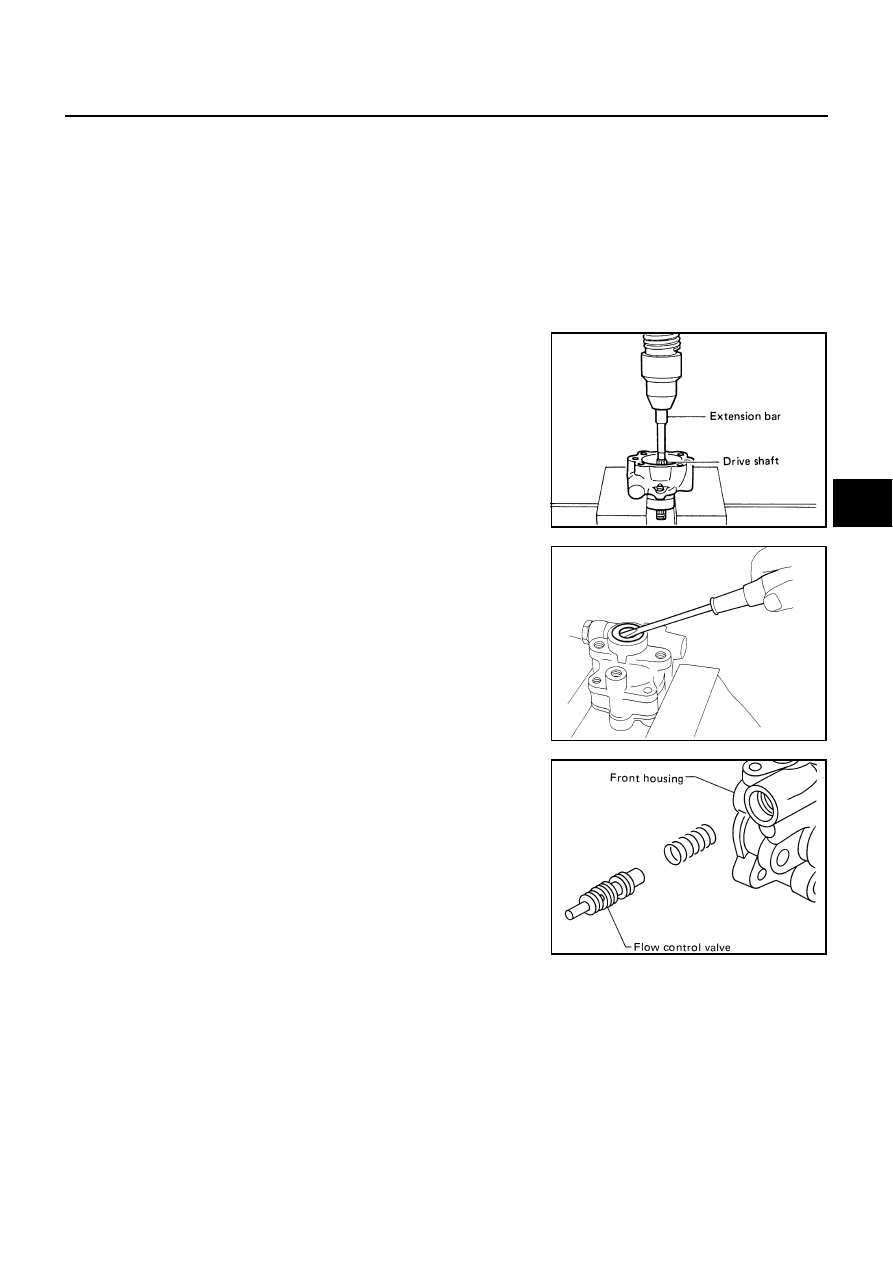

Remove snap ring from drive shaft assembly and press out it.

CAUTION:

When removing snap ring, be careful not to damage drive

shaft assembly.

7.

Remove oil seal from body assembly using a flat-bladed screw-

driver.

CAUTION:

Do not damage body assembly.

8.

Remove O-ring from body assembly.

9.

Loosen eye bolt and remove joint and washer, then pull out flow

control valve and spring from body assembly.

CAUTION:

Be careful not to drop and deform the flow control valve.

10. Remove suction pipe from body assembly.

11. Remove O-ring for suction pipe.

INSPECTION AFTER DISASSEMBLY

Body Assembly and Rear Cover Inspection

Check body assembly and the inside of rear cover for damage. If any damage is found, replace with new part

for rear cover, and replace with new power steering pump assembly for body assembly.

Cartridge Assembly Inspection

Check cam ring, side plate, rotor and vane for damage. If any damage is found, replace cartridge assembly

with new one.

Side Plate Inspection

Check side plate for damage. Replace side plate if there are.

SST010B

SST034A

SST036A