Nissan Murano Z50 (2006 year). Manual - part 162

AUTO LIGHT SYSTEM

LT-91

C

D

E

F

G

H

I

J

L

M

A

B

LT

Revision: 2006 August

2006 Murano

CONSULT-II Functions (BCM)

NKS001P2

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

Refer to

GI-38, "CONSULT-II Start Procedure"

.

WORK SUPPORT

Operation Procedure

1.

Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2.

Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

3.

Touch “CUSTOM A/LIGHT SETTING” or “ILL DELAY SET” on “SELECT WORK ITEM” screen.

4.

Touch “START”.

5.

Touch “NORMAL” or “MODE 2 - 4” of setting to be changed (CUSTOM A/LIGHT SETTING) or touch

“MODE1–8” of setting to be changed (ILL DELAY SET).

6.

Touch “SETTING CHANGE”.

7.

The setting will be changed and “CUSTOMIZING COMPLETED” will be displayed.

8.

Touch “END”.

Work Support Setting Item

Sensitivity of auto light can be selected and set from four modes.

DATA MONITOR

Operation Procedure

1.

Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2.

Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3.

Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on “SELECT MONITOR ITEM” screen.

4.

When “SELECTION FROM MENU” is selected, touch individual items to be monitored. When “ALL SIG-

NALS” is selected, all the items will be monitored.

5.

Touch “START”.

6.

Touch “RECORD” while monitoring, then the status of the monitored item can be recorded. To stop

recording, touch “STOP”.

Display Item List

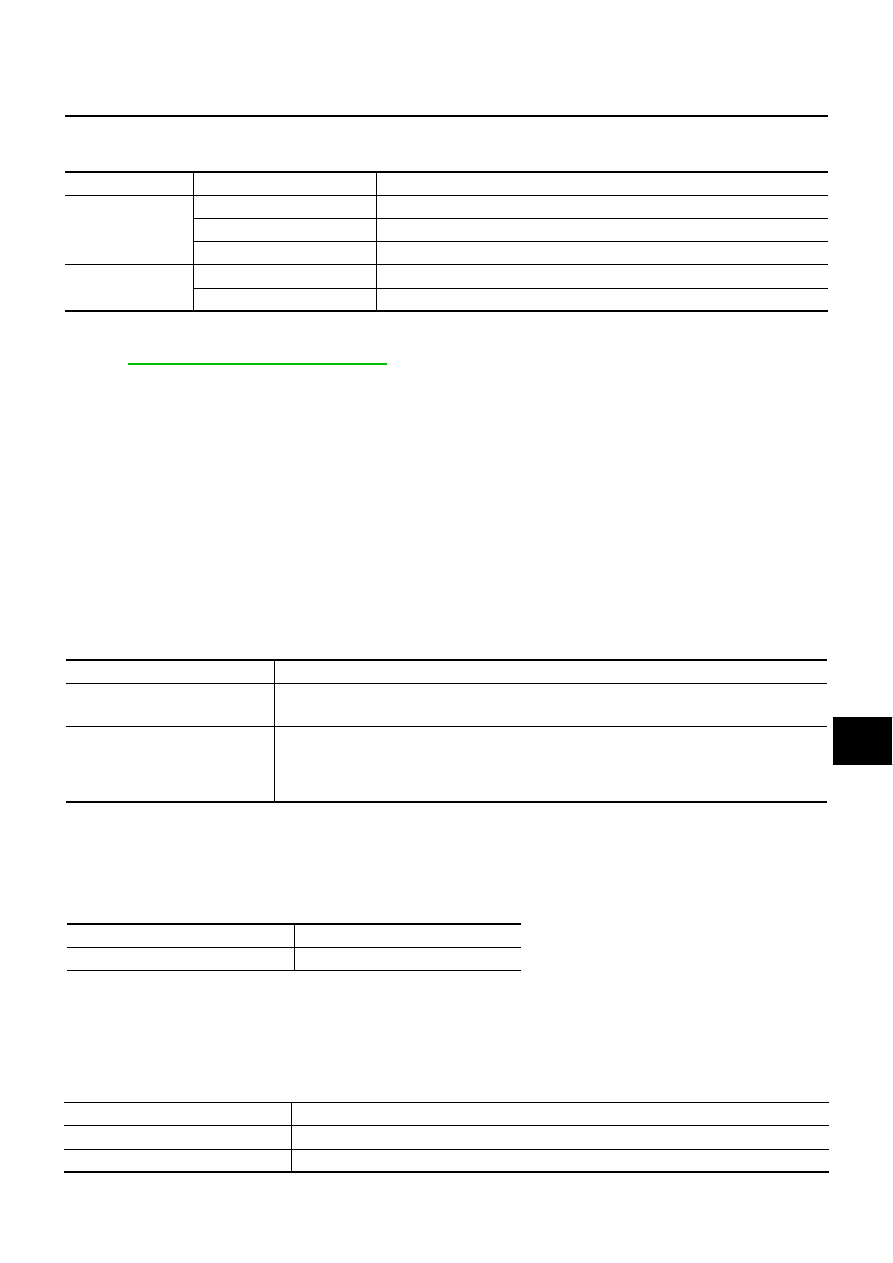

BCM diagnosis part

Diagnosis mode

Description

HEADLAMP

WORK SUPPORT

Changes the setting for each function.

DATA MONITOR

Displays BCM input data in real time.

ACTIVE TEST

Operation of electrical loads can be checked by sending drive signal to them.

BCM

SELF-DIAG RESULTS

BCM performs self-diagnosis of CAN communication.

CAN DIAG SUPPORT MNTR

The result of transmit/receive diagnosis of CAN communication can be read.

Work item

Description

CUSTOM A/LIGHT SETTING

Auto light sensitivity can be changed in this mode. Sensitivity can be adjusted in four modes.

●

MODE 1 (Normal)/ MODE 2 (sensitive)/MODE 3 (Desensitized)/MODE4 (Insensitive)

ILL DELAY SET

Auto light delay off timer period can be changed in this mode. Selects auto light delay off timer

period among eight modes.

●

MODE 1 (45 sec.)/MODE 2 (OFF)/MODE 3 (30 sec.)/MODE 4 (60 sec.)/MODE 5 (90 sec.)/

MODE 6 (120 sec.)/MODE 7 (150 sec.)/MODE 8 (180 sec.)

ALL SIGNALS

Monitors all the signals.

SELECTION FROM MENU

Selects items and monitors them.

Monitor item

Contents

IGN ON SW

“ON/OFF”

Displays “IGN position (ON)/OFF, ACC position (OFF)” judged from the ignition switch signal.

ACC ON SW

“ON/OFF”

Displays “ACC (ON)/OFF, Ignition OFF (OFF)” status judged from ignition switch signal.