Nissan Murano Z50 (2006 year). Manual - part 130

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-149

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision: 2006 August

2006 Murano

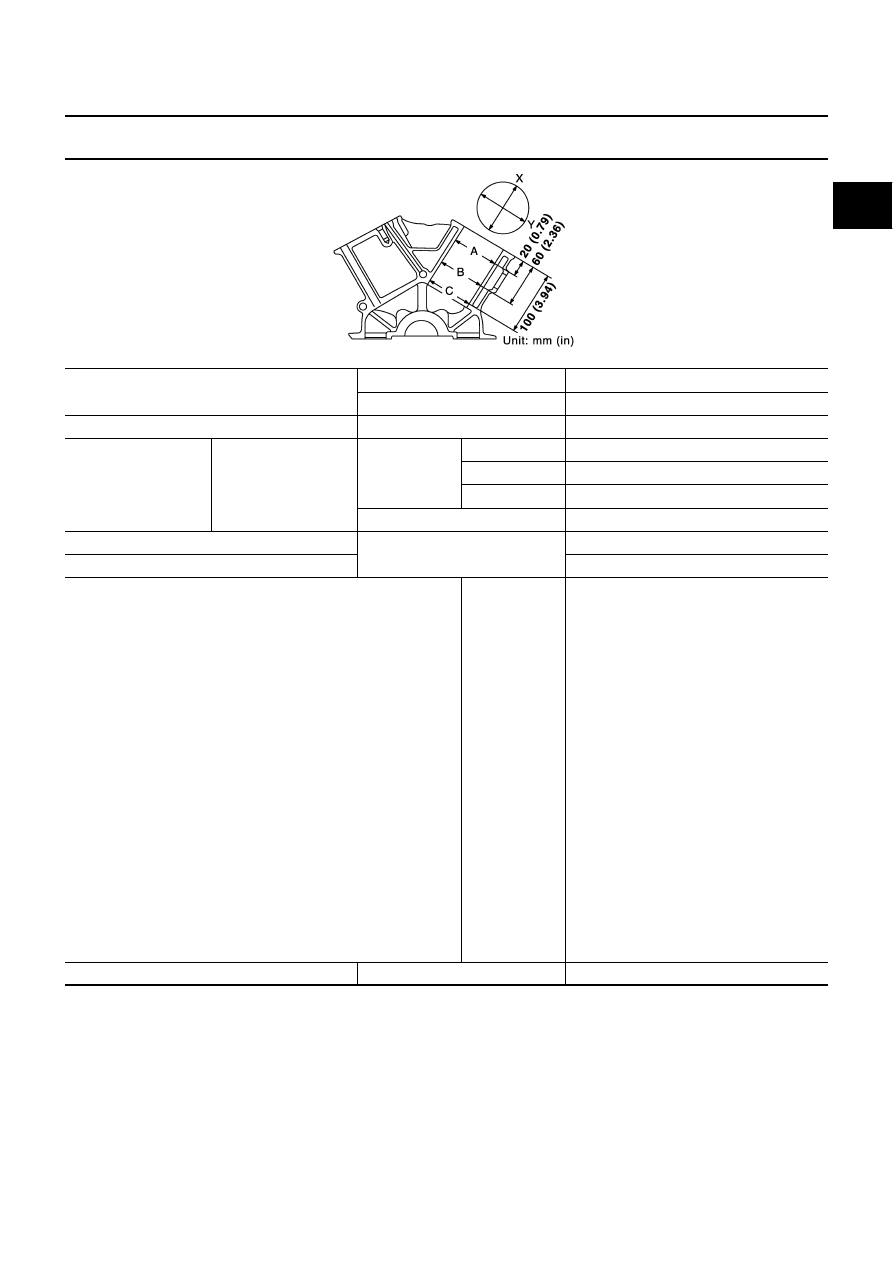

CYLINDER BLOCK

Unit: mm (in)

Surface flatness

Standard

Less than 0.03 (0.0012)

Limit

0.1 (0.004)

Main bearing housing inner diameter

Standard

63.993 - 64.017 (2.5194 - 2.5203)

Cylinder bore

Inner diameter

Standard

Grade No. 1

95.500 - 95.510 (3.7598 - 3.7602)

Grade No. 2

95.510 - 95.520 (3.7602 - 3.7606)

Grade No. 3

95.520 - 95.530 (3.7606 - 3.7610)

Wear limit

0.2 (0.008)

Out-of-round (Difference between “X” and “Y”)

Limit

0.015 (0.0006)

Taper (Difference between “A” and “C”)

0.01 (0.0004)

Main bearing housing inner diameter (Without bearing)

Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 7

63.993 - 63.994 (2.5194 - 2.5194)

63.994 - 63.995 (2.5194 - 2.5195)

63.995 - 63.996 (2.5195 - 2.5195)

63.996 - 63.997 (2.5195 - 2.5196)

63.997 - 63.998 (2.5196 - 2.5196)

63.998 - 63.999 (2.5196 - 2.5196)

63.999 - 64.000 (2.5196 - 2.5197)

64.000 - 64.001 (2.5197 - 2.5197)

64.001 - 64.002 (2.5197 - 2.5198)

64.002 - 64.003 (2.5198 - 2.5198)

64.003 - 64.004 (2.5198 - 2.5198)

64.004 - 64.005 (2.5198 - 2.5199)

64.005 - 64.006 (2.5199 - 2.5199)

64.006 - 64.007 (2.5199 - 2.5200)

64.007 - 64.008 (2.5200 - 2.5200)

64.008 - 64.009 (2.5200 - 2.5200)

64.009 - 64.010 (2.5200 - 2.5201)

64.010 - 64.011 (2.5201 - 2.5201)

64.011 - 64.012 (2.5201 - 2.5202)

64.012 - 64.013 (2.5202 - 2.5202)

64.013 - 64.014 (2.5202 - 2.5202)

64.014 - 64.015 (2.5202 - 2.5203)

64.015 - 64.016 (2.5203 - 2.5203)

64.016 - 64.017 (2.5203 - 2.5203)

Difference in inner diameter between cylinders

Standard

Less than 0.03 (0.0012)

PBIC0923E