Nissan Murano Z50 (2006 year). Manual - part 120

ROOF RAIL

EI-29

C

D

E

F

G

H

J

K

L

M

A

B

EI

Revision: 2006 August

2006 Murano

ROOF RAIL

PFP:73820

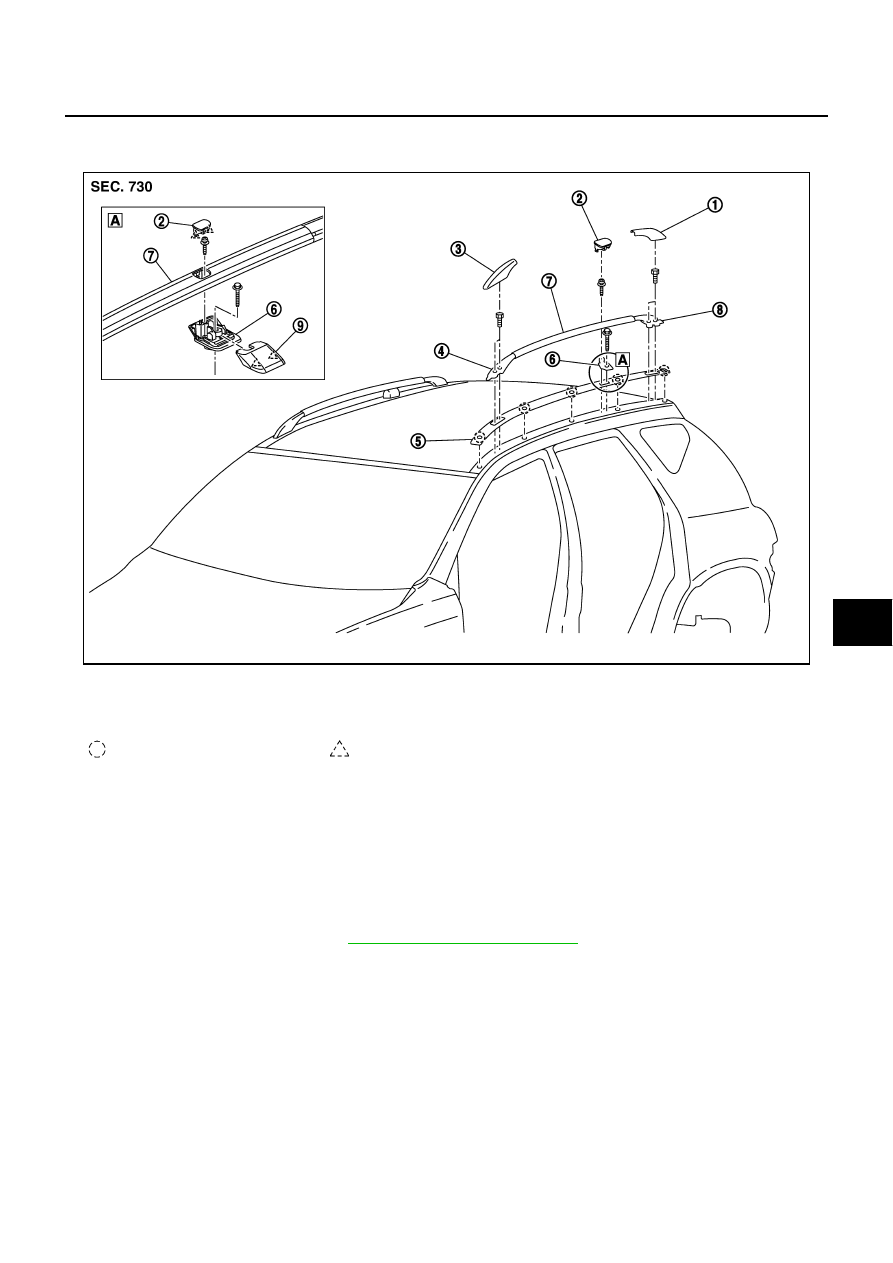

Removal and Installation

NIS001EA

REMOVAL

1.

Remove roof rail front cover and rear cover.

2.

Remove roof rail center cap.

3.

Remove roof rail front/rear leg mounting bolts and remove roof rail center mounting bolt.

4.

Remove roof rail assembly.

5.

Remove roof rail center cover.

6.

Remove roof rail center leg mounting bolt and remove roof center leg.

7.

Remove roof side molding. Refer to

EI-28, "Removal and Installation"

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Match the position to location pin and assembly center leg and rail assembly.

PIIB7407E

1.

Roof rail rear cover

2.

Roof rail center cap

3.

Roof rail front cover

4.

Roof rail front leg

5.

Roof side molding

6.

Roof rail center leg

7.

Roof rail assembly

8.

Roof rail rear leg

9.

Roof rail center cover

Clip

Pawl