Nissan Murano Z50 (2006 year). Manual - part 115

ASCD INDICATOR

EC-619

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 August

2006 Murano

Diagnostic Procedure

NBS003EM

1.

CHECK OVERALL FUNCTION

Check ASCD indicator under the following conditions.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 2.

2.

CHECK DTC

Check that DTC U1000 or U1001 is not displayed.

OK or NG

OK

>> GO TO 3.

NG

>> Perform trouble diagnoses for DTC U1000, U1001. Refer to

.

3.

CHECK DTC WITH “UNIFIED METER AND A/C AMP.”

Refer to

OK or NG

OK

>> GO TO 4.

NG

DI-34, "DTC [B2202] Meter Communication Circuit"

4.

CHECK INTERMITTENT INCIDENT

Refer to

EC-142, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

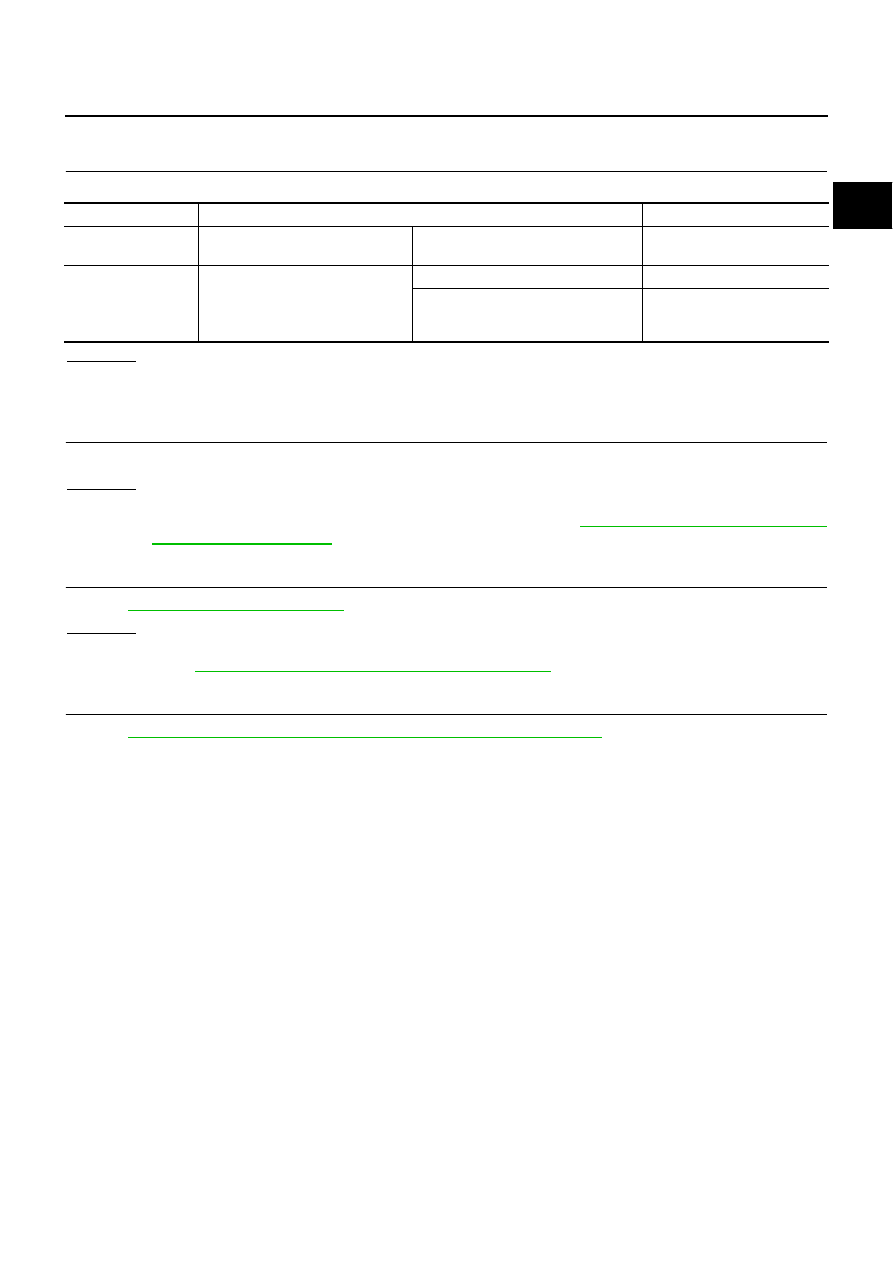

MONITOR ITEM

CONDITION

SPECIFICATION

CRUISE LAMP

●

Ignition switch: ON

MAIN switch: Pressed at the 1st time

→

at the 2nd time

ON

→

OFF

SET LAMP

●

MAIN switch: ON

●

When vehicle speed is between

40 km/h (25 MPH) and 144 km/h

(89 MPH)

ASCD: Operating

ON

ASCD: Not operating

OFF