Nissan Murano Z50 (2006 year). Manual - part 111

DTC P2100, P2103 THROTTLE CONTROL MOTOR RELAY

EC-555

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 August

2006 Murano

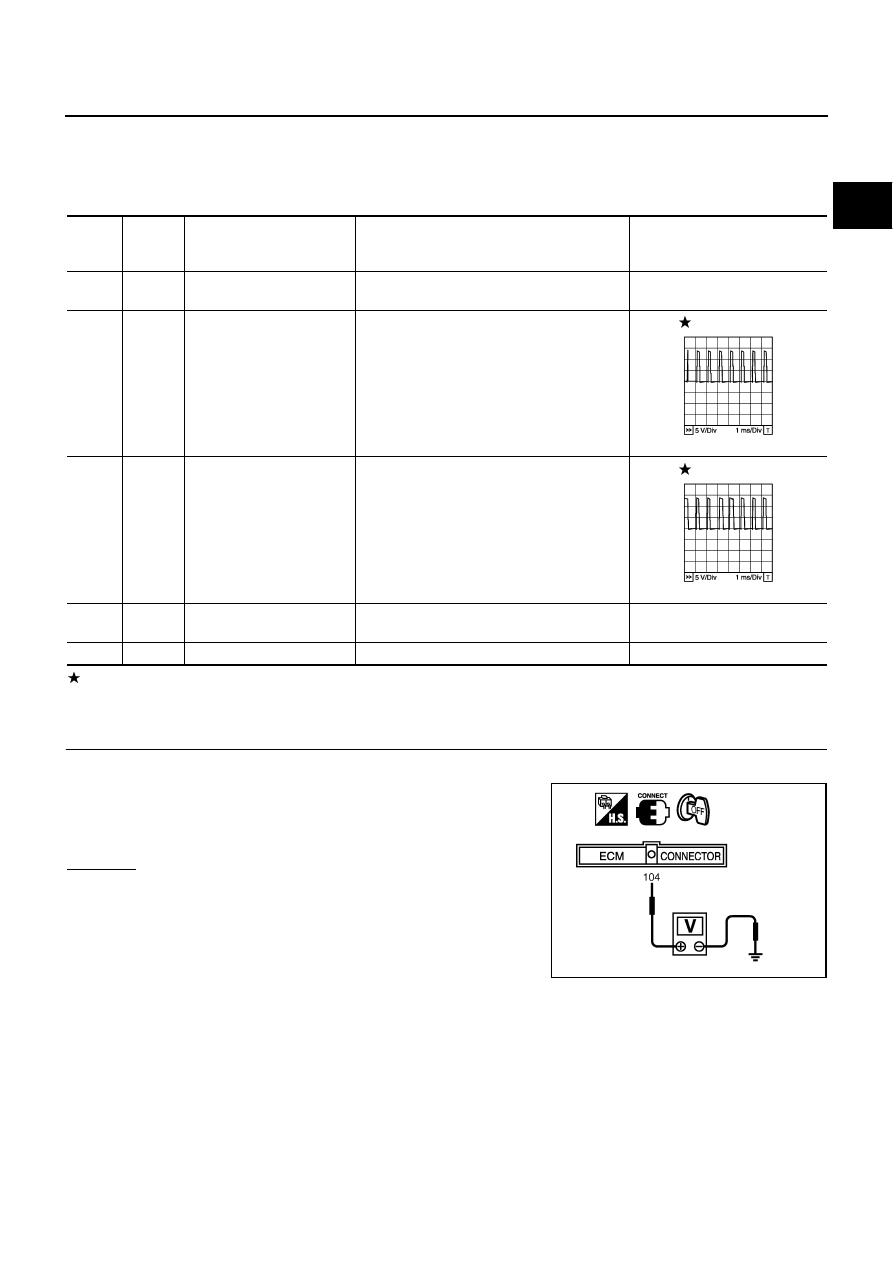

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnostic Procedure

NBS0037R

1.

CHECK THROTTLE CONTROL MOTOR RELAY POWER SUPPLY CIRCUIT-I

1.

Turn ignition switch OFF.

2.

Check voltage between ECM terminal 104 and ground with

CONSULT-II or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 2.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

3

R

Throttle control motor relay

power supply

[Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14V)

4

G

Throttle control motor

(Close)

[Ignition switch: ON]

●

Engine stopped

●

Shift lever: D

●

Accelerator pedal: Fully released

0 - 14V

5

R

Throttle control motor

(Open)

[Ignition switch: ON]

●

Engine stopped

●

Shift lever: D

●

Accelerator pedal: Fully depressed

0 - 14V

104

P/L

Throttle control motor relay

[Ignition switch: OFF]

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch: ON]

0 - 1.0V

PBIB1104E

PBIB1105E

Voltage: Battery voltage

PBIB1171E