Nissan Murano Z50 (2006 year). Manual - part 77

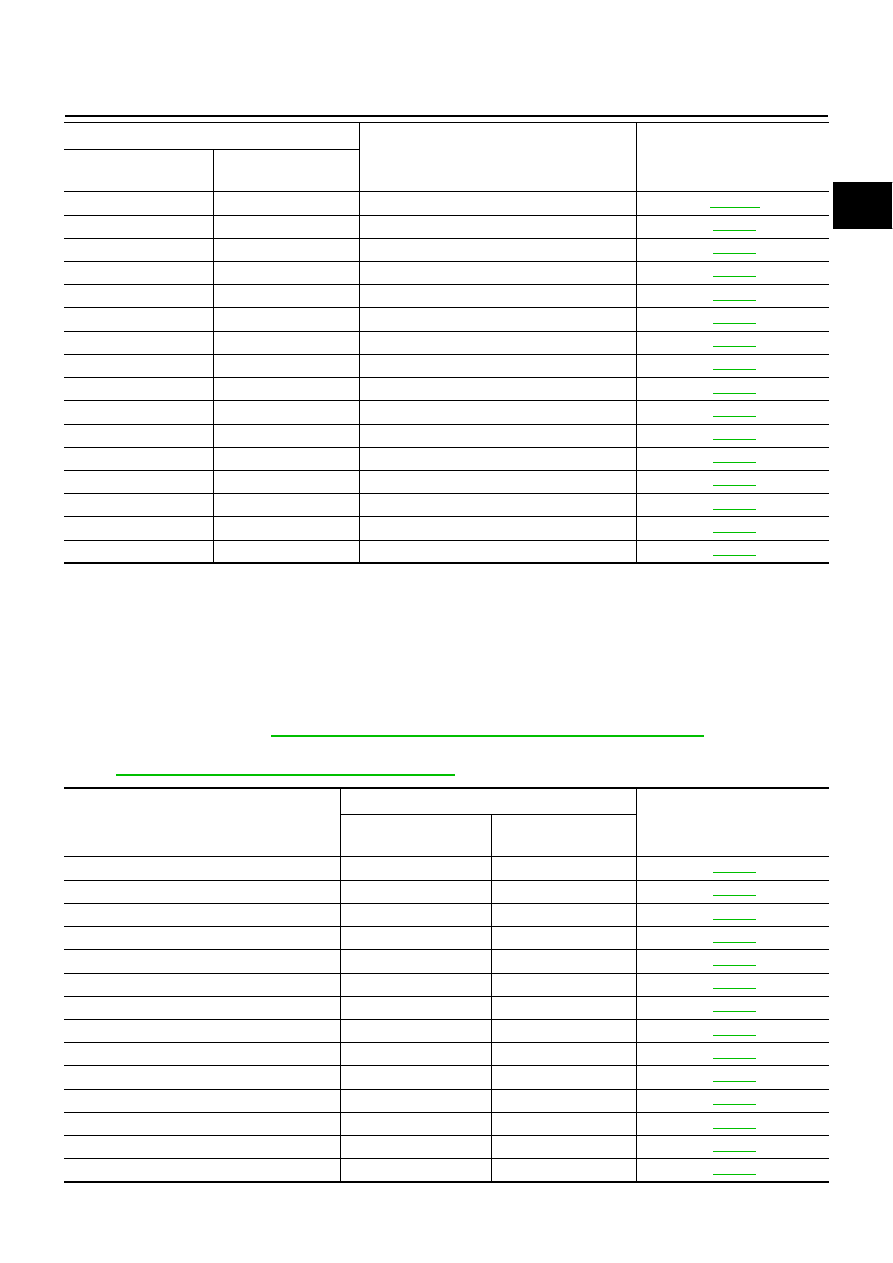

INDEX FOR DTC

EC-11

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 August

2006 Murano

*1: 1st trip DTC No. is the same as DTC No.

*2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN.

*4: The troubleshooting for this DTC needs CONSULT-II.

*5: When the fail-safe operations for both self-diagnoses occur at the same time, the MIL illuminates.

Alphabetical Index

NBS003F2

NOTE:

●

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to

EC-152, "DTC U1000, U1001 CAN COMMUNICATION LINE"

.

●

If DTC U1010 is displayed with other DTC, first perform the trouble diagnosis for DTC U1010. Refer

to

EC-155, "DTC U1010 CAN COMMUNICATION"

P1778

1778

STEP MOTR FNC

P1800

1800

VIAS S/V CIRC

P1805

1805

BRAKE SW/CIRCUIT

P2100

2100

ETC MOT PWR

P2101

2101

ETC FUNCTION/CIRC

P2103

2103

ETC MOT PWR

P2118

2118

ETC MOT

P2119

2119

ETC ACTR

P2122

2122

APP SEN 1/CIRC

P2123

2123

APP SEN 1/CIRC

P2127

2127

APP SEN 2/CIRC

P2128

2128

APP SEN 2/CIRC

P2135

2135

TP SENSOR

P2138

2138

APP SENSOR

P2A00

2A00

A/F SENSOR1 (B1)

P2A03

2A03

A/F SENSOR1 (B2)

DTC*

1

Items

(CONSULT-II screen terms)

Reference page

CONSULT-II

GST*

2

ECM*

3

Items

(CONSULT-II screen terms)

DTC*

1

Reference page

CONSULT-II

GST*

2

ECM*

3

A/F SEN1 HTR (B1)

P0031

0031

A/F SEN1 HTR (B1)

P0032

0032

A/F SEN1 HTR (B2)

P0051

0051

A/F SEN1 HTR (B2)

P0052

0052

A/F SENSOR1 (B1)

P0130

0130

A/F SENSOR1 (B1)

P0131

0131

A/F SENSOR1 (B1)

P0132

0132

A/F SENSOR1 (B1)

P0133

0133

A/F SENSOR1 (B1)

P2A00

2A00

A/F SENSOR1 (B2)

P0150

0150

A/F SENSOR1 (B2)

P0151

0151

A/F SENSOR1 (B2)

P0152

0152

A/F SENSOR1 (B2)

P0153

0153

A/F SENSOR1 (B2)

P2A03

2A03