Nissan Murano Z50 (2006 year). Manual - part 70

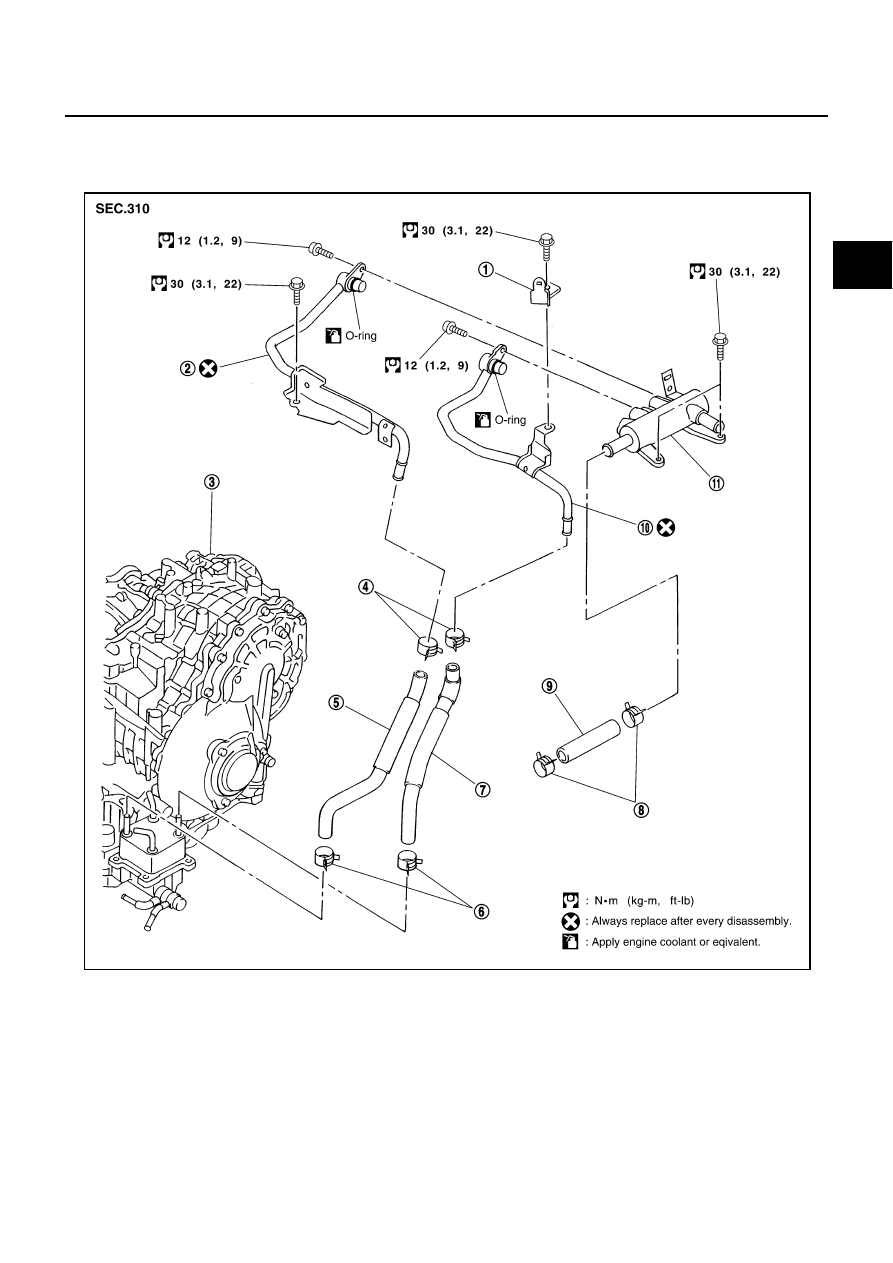

CVT FLUID COOLER VALVE

CVT-225

D

E

F

G

H

I

J

K

L

M

A

B

CVT

Revision: 2006 August

2006 Murano

CVT FLUID COOLER VALVE

PFP:21630

Removal and Installation

NCS0019J

COMPONENTS

1.

Harness bracket

2.

CVT fluid cooler inlet tube assembly 3.

Transaxle assembly

4.

Hose clamp

5.

Inlet water hose

6.

Hose clamp

7.

Outlet water hose

8.

Hose clamp

9.

Heater hose

10. CVT fluid cooler outlet tube assem-

bly

11.

CVT fluid cooler valve assembly

SCIA4344E