Nissan Murano Z50 (2006 year). Manual - part 69

SHIFT CONTROL SYSTEM

CVT-209

D

E

F

G

H

I

J

K

L

M

A

B

CVT

Revision: 2006 August

2006 Murano

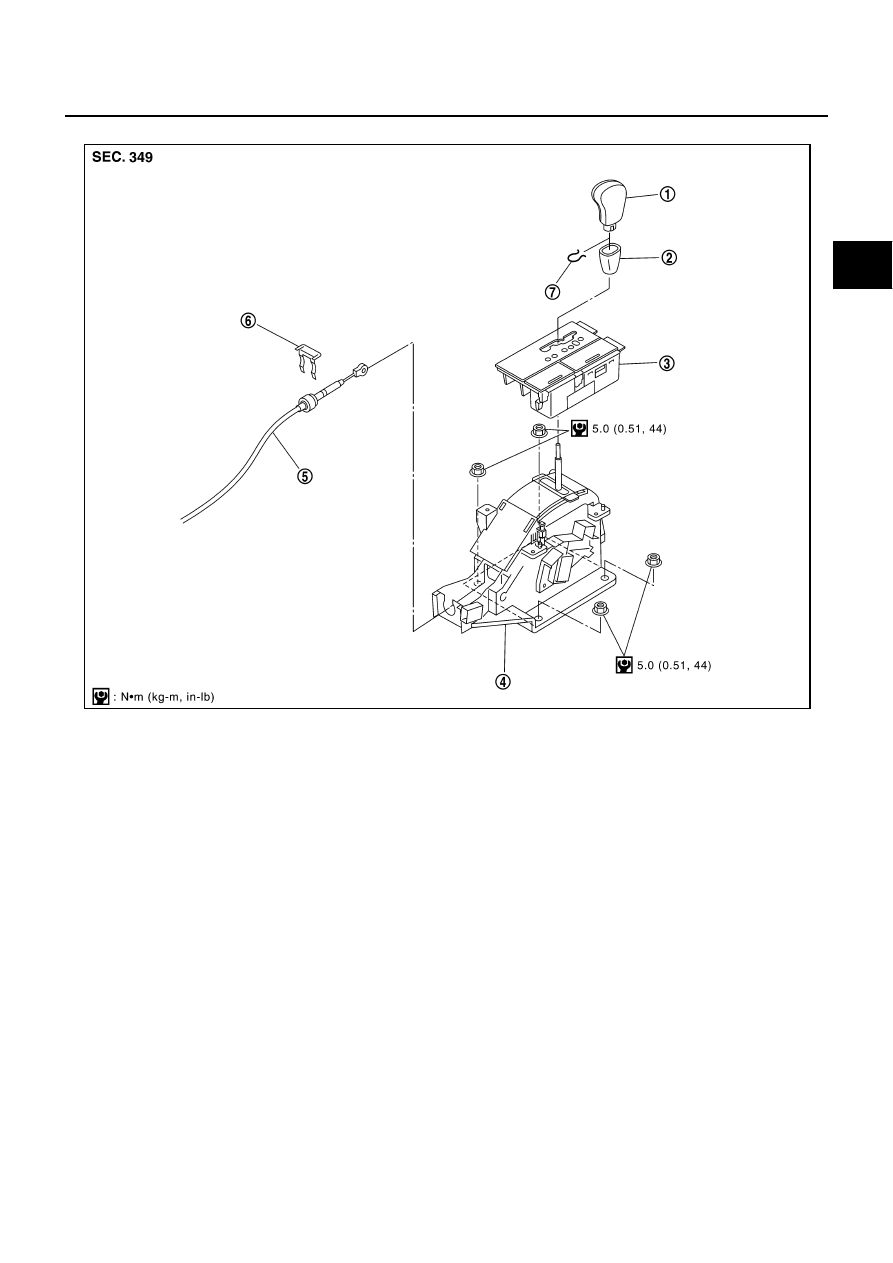

CONTROL DEVICE COMPONENTS (WITHOUT MANUAL MODE)

1.

Selector lever knob

2.

Knob cover

3.

A/T console finisher

4.

Control device assembly

5.

Control cable

6.

Lock plate

7.

Lock pin

SCIA6464E