Nissan Murano Z50 (2006 year). Manual - part 46

BRAKE MASTER CYLINDER

BR-19

C

D

E

G

H

I

J

K

L

M

A

B

BR

Revision: 2006 August

2006 Murano

6.

Using a pin punch [commercial service tool: diameter approx. 4

mm (0.16 in)], insert the reservoir tank mounting pin into the pin

hole so that the attachment side and the opposite side are iden-

tical.

CAUTION:

Do not reuse reservoir tank grommet and mounting pin.

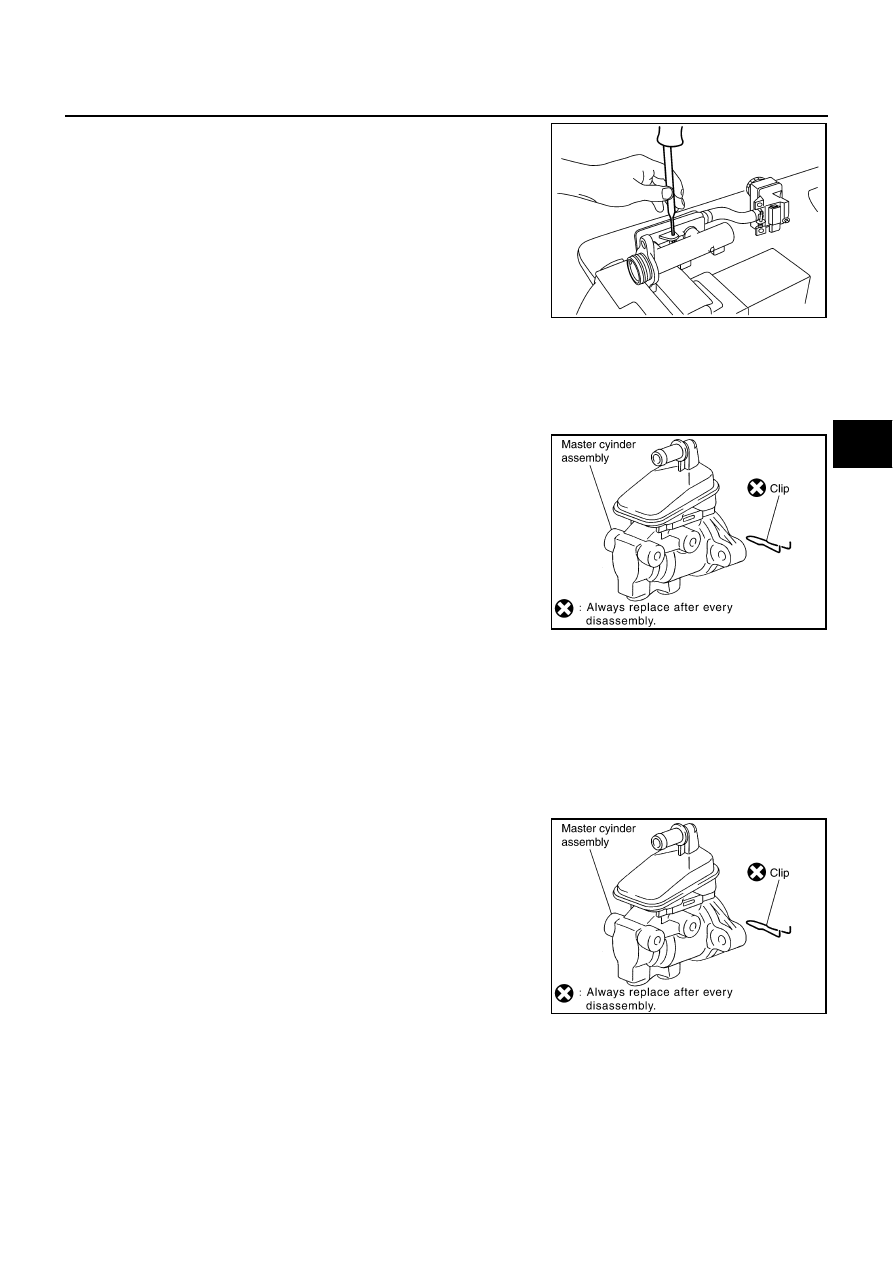

WITH VDC MODELS

Disassembly

CAUTION:

●

Master cylinder can not be disassembled.

●

Remove the reservoir tank only when absolutely necessary.

1.

Remove clip.

2.

Remove reservoir tank and grommet from cylinder body.

Assembly

CAUTION:

●

Do not use mineral oils such as kerosene, gasoline during the cleaning and assembly process.

●

Do not drop parts. If a part is dropped, do not use it.

1.

Apply brake fluid the grommet and attach to the cylinder body.

CAUTION:

Do not reuse the grommet.

2.

Install reservoir tank onto the cylinder body.

3.

Insert the clip.

PFIA0439E

PFIA0424E

PFIA0424E