Nissan Murano Z50 (2005 year). Manual - part 189

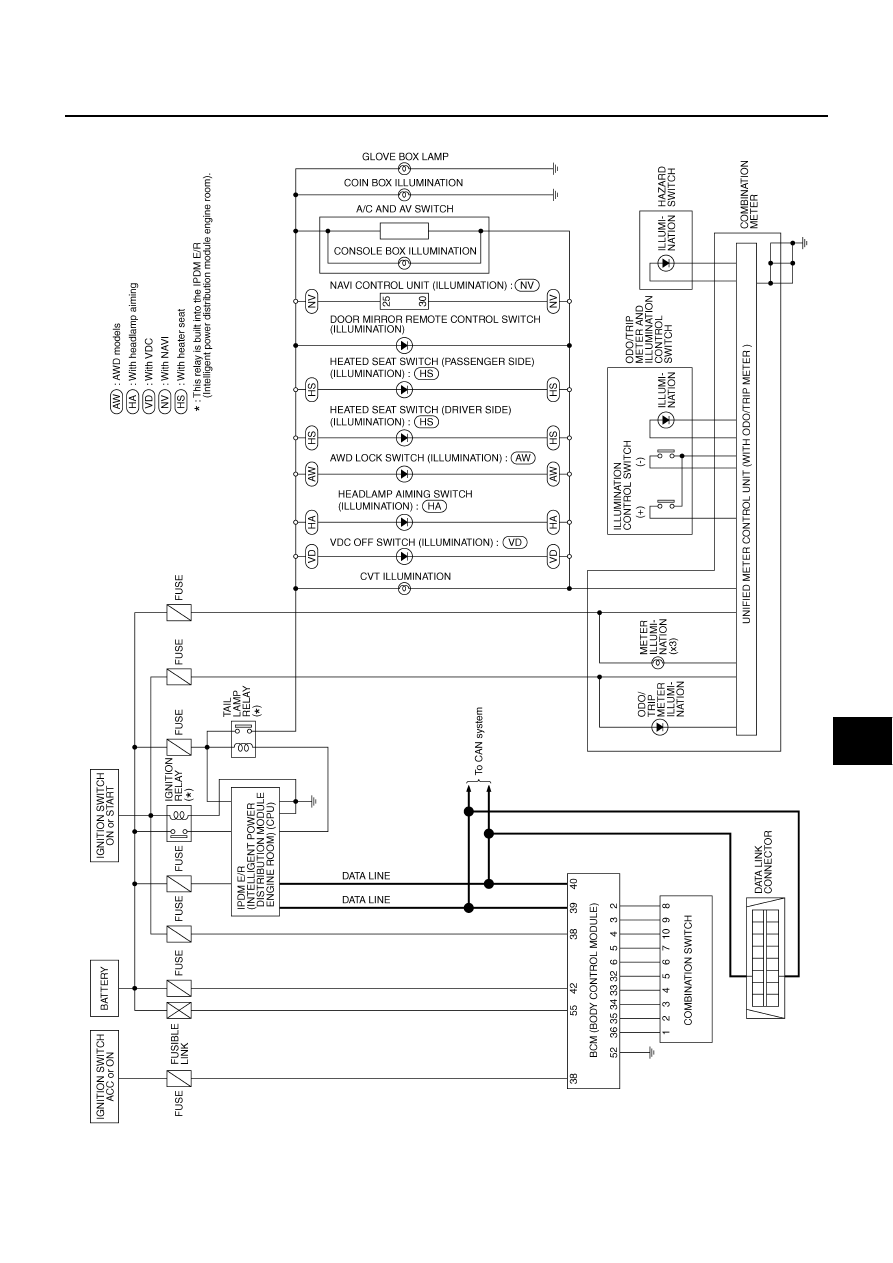

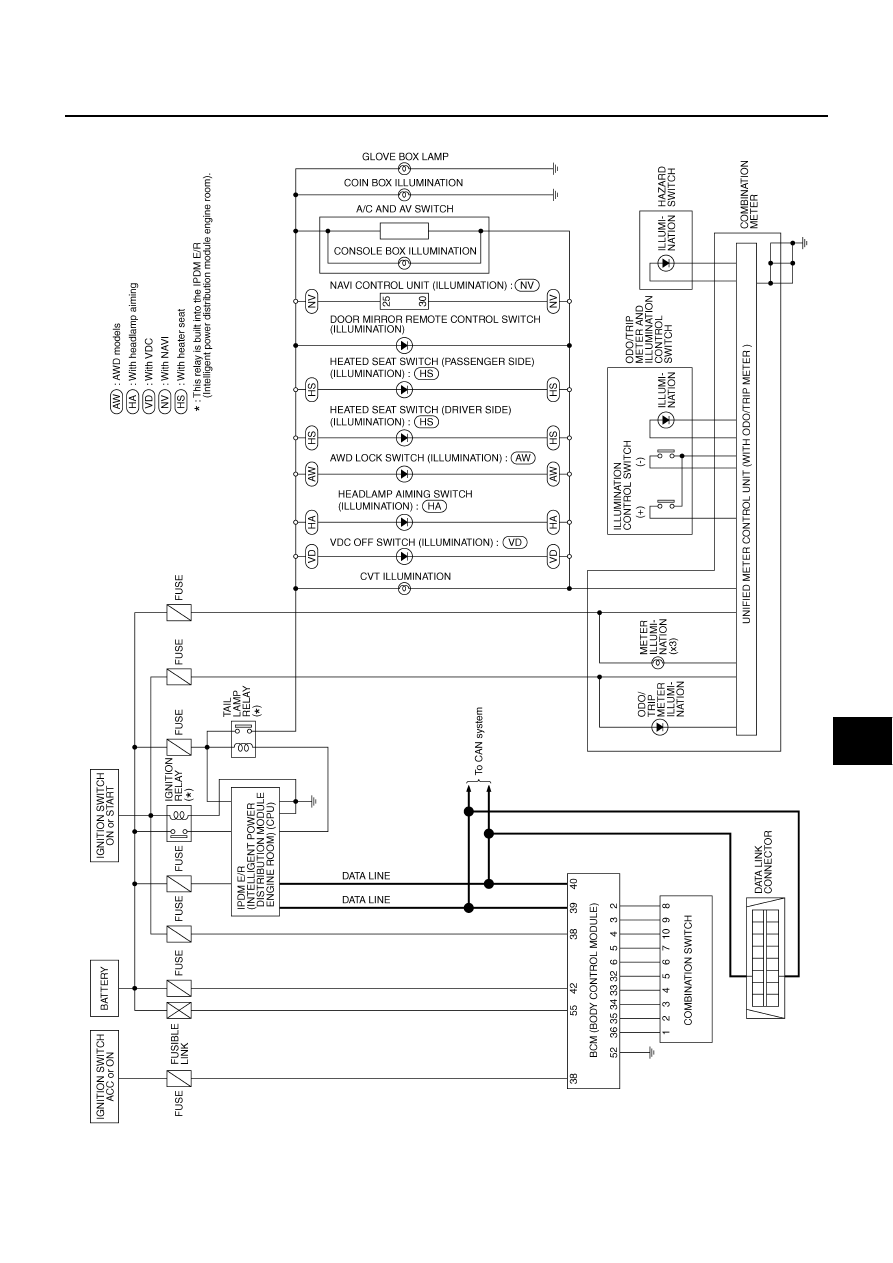

ILLUMINATION

LT-211

C

D

E

F

G

H

I

J

L

M

A

B

LT

Revision: 2005 August

2005 Murano

Schematic

AKS004MJ

TKWB0476E

|

|

|

ILLUMINATION LT-211 C D E F G H I J L M A B LT Revision: 2005 August 2005 Murano Schematic AKS004MJ TKWB0476E |