Nissan Murano Z50 (2005 year). Manual - part 134

EXHAUST SYSTEM

EX-3

C

D

E

F

G

H

I

J

K

L

M

A

EX

Revision: 2005 August

2005 Murano

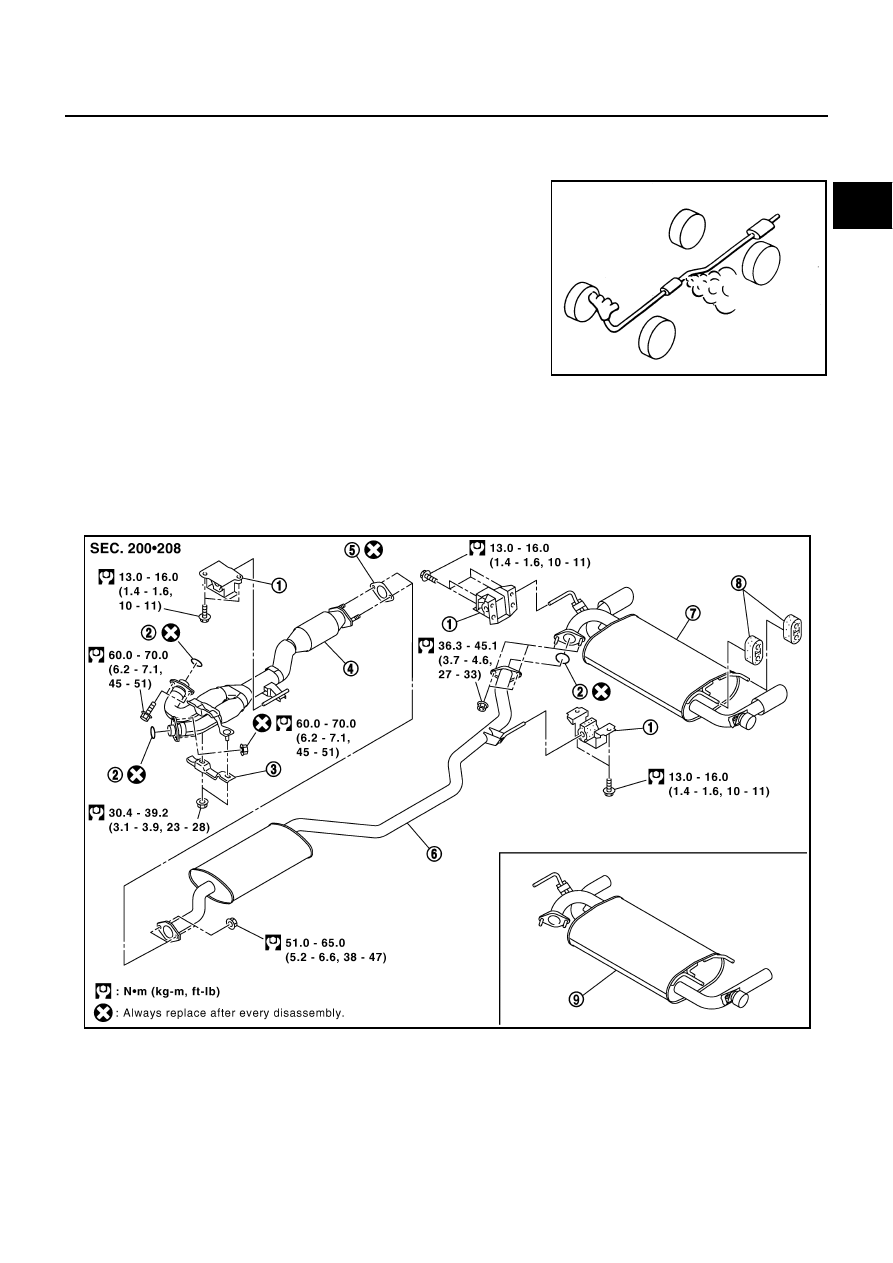

EXHAUST SYSTEM

PFP:20100

Checking Exhaust System

ABS0033U

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration.

●

If anything found, repair or replace damage parts.

Removal and Installation

ABS0033V

CAUTION:

●

Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

●

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

●

Be careful not to cut your hand on heat insulator edge.

REMOVAL

Disconnect each joint and mounting using power tool.

SMA211A

1.

Mounting bracket

2.

Ring gasket

3.

Exhaust front tube bracket

4.

Exhaust front tube

5.

Gasket

6.

Center muffler

7.

Main muffler

8.

Mounting rubber

9.

Main muffler (GXE grade)

PBIC1777E