Nissan Murano Z50 (2005 year). Manual - part 125

DRIVE BELTS

EM-13

C

D

E

F

G

H

I

J

K

L

M

A

EM

Revision: 2005 August

2005 Murano

DRIVE BELTS

PFP:02117

Checking Drive Belts

ABS00329

WARNING:

Be sure to perform when the engine is stopped.

1.

Inspect belts for cracks, fraying, wear and oil. If necessary, replace.

2.

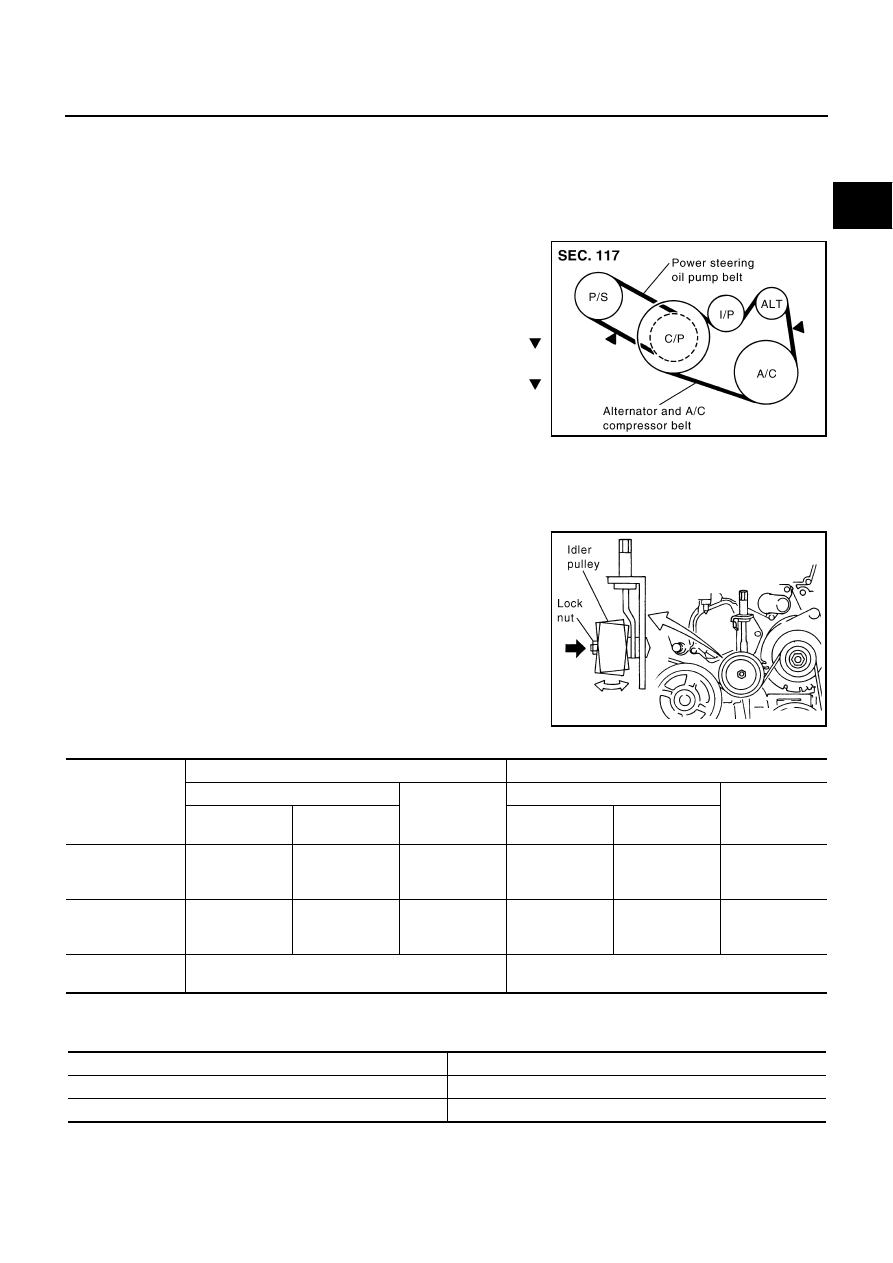

Inspect drive belt deflection or tension at a point on belt midway

between pulleys.

●

Inspection should be done only when the engine is cold, or

over 30 minutes after engine is stopped.

●

Measure the belt tension with belt tension gauge (commercial

service tool: BT3373-F or equivalent) at points marked

shown in the figure.

●

When measuring deflection, apply 98 N (10 kg, 22 lb) at the

marked point.

●

Adjust if the belt deflection exceeds the limit or if the belt ten-

sion is not within specifications.

CAUTION:

●

When checking the belt deflection or the tension immediately after installation, first adjust it to

the specified value. Then, after turning the crankshaft two turns or more, re-adjust to the speci-

fied value to avoid variation in deflection between pulleys.

●

Tighten idler pulley lock nut by hand and measure the

deflection or the tension without looseness.

Belt Deflection and Tension

*: If belt tension gauge cannot be installed at check points shown, check drive belt tension at different location on the belt.

Tension Adjustment

ABS0036V

CAUTION:

●

When belt is replaced with a new one, adjust it to value for “New belt” to accommodate for insuffi-

cient adaptability with pulley grooves.

PBIC2449E

PBIC1162E

Deflection adjustment

Unit: mm (in)

Tension adjustment*

Unit: mm (in)

Used belt

New belt

Used belt

New belt

Limit

After adjustment

Limit

After adjust-

ment

Alternator and A/C

compressor

7 (0.28)

4.2 - 4.6

(0.17 - 0.18)

3.7 - 4.1

(0.15 - 0.16)

294 (30, 66)

730 - 818

(74.5 - 83.5,

164 - 184)

838 - 926

(85.5 - 94.5,

188 - 208)

Power steering oil

pump

11 (0.43)

7.3 - 8

(0.29 - 0.30)

6.5 - 7.2

(0.26 - 0.28)

196 (20, 44)

495 - 583

(50.5 - 59.5,

111 - 131)

603 - 691

(61.5 - 70.5,

135.6 - 155.4)

Applied pushing

force

98 N (10 Kg, 22 lb)

—

Portion

Belt tightening method for adjustment

Power steering oil pump belt

Adjusting bolt on power steering oil pump

Alternator and A/C compressor belt

Adjusting nut on idler pulley