Nissan Murano Z50 (2005 year). Manual - part 121

ASCD BRAKE SWITCH

EC-691

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2005 August

2005 Murano

2.

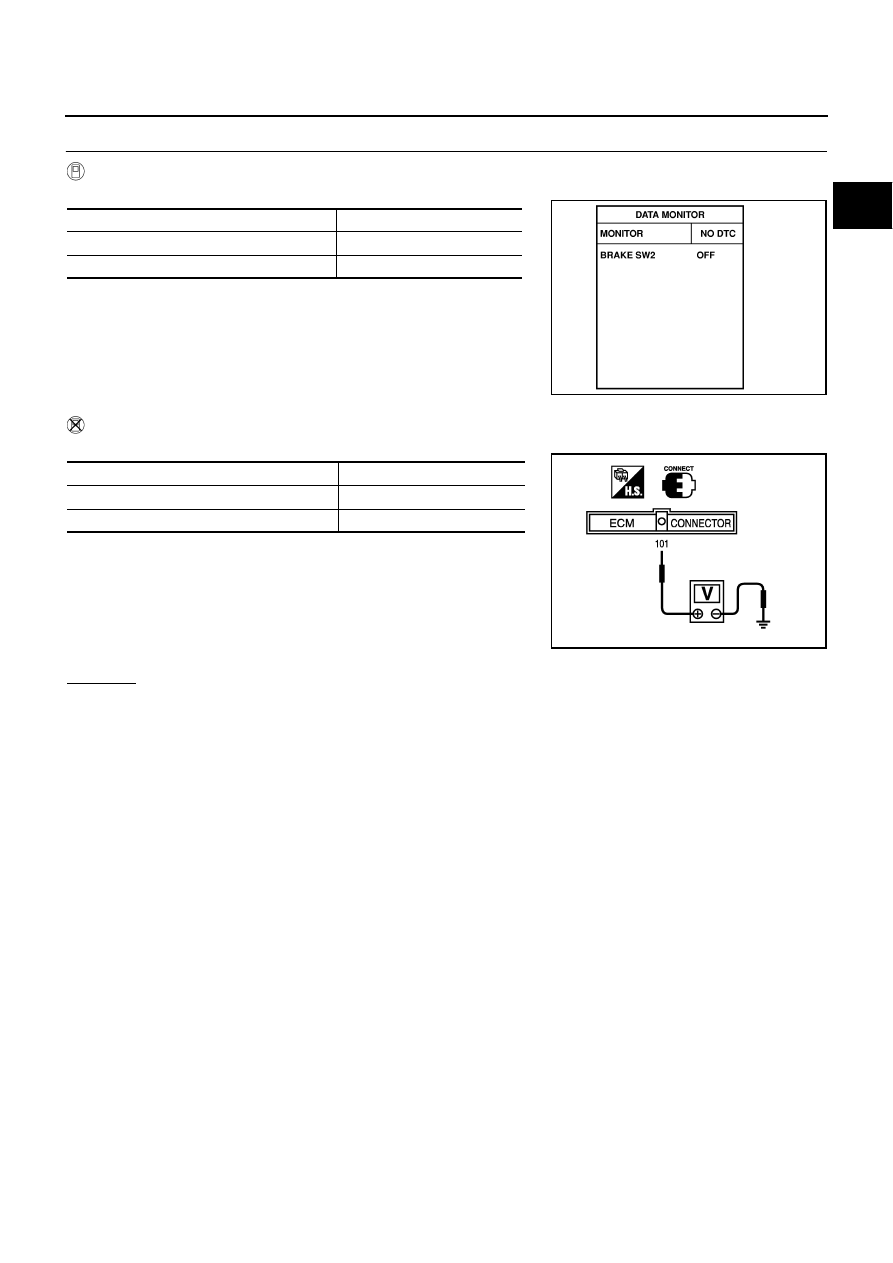

CHECK OVERALL FUNCTION-II

With CONSULT-II

Check “BRAKE SW2” indication in “DATA MONITOR” mode.

Without CONSULT-II

Check voltage between ECM terminal 101 and ground under the following conditions.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 8.

CONDITION

INDICATION

Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed

ON

SEC013D

CONDITION

VOLTAGE

Brake pedal: Fully released

Approximately 0V

Brake pedal: Slightly depressed

Battery voltage

MBIB0060E