Nissan Murano Z50 (2005 year). Manual - part 94

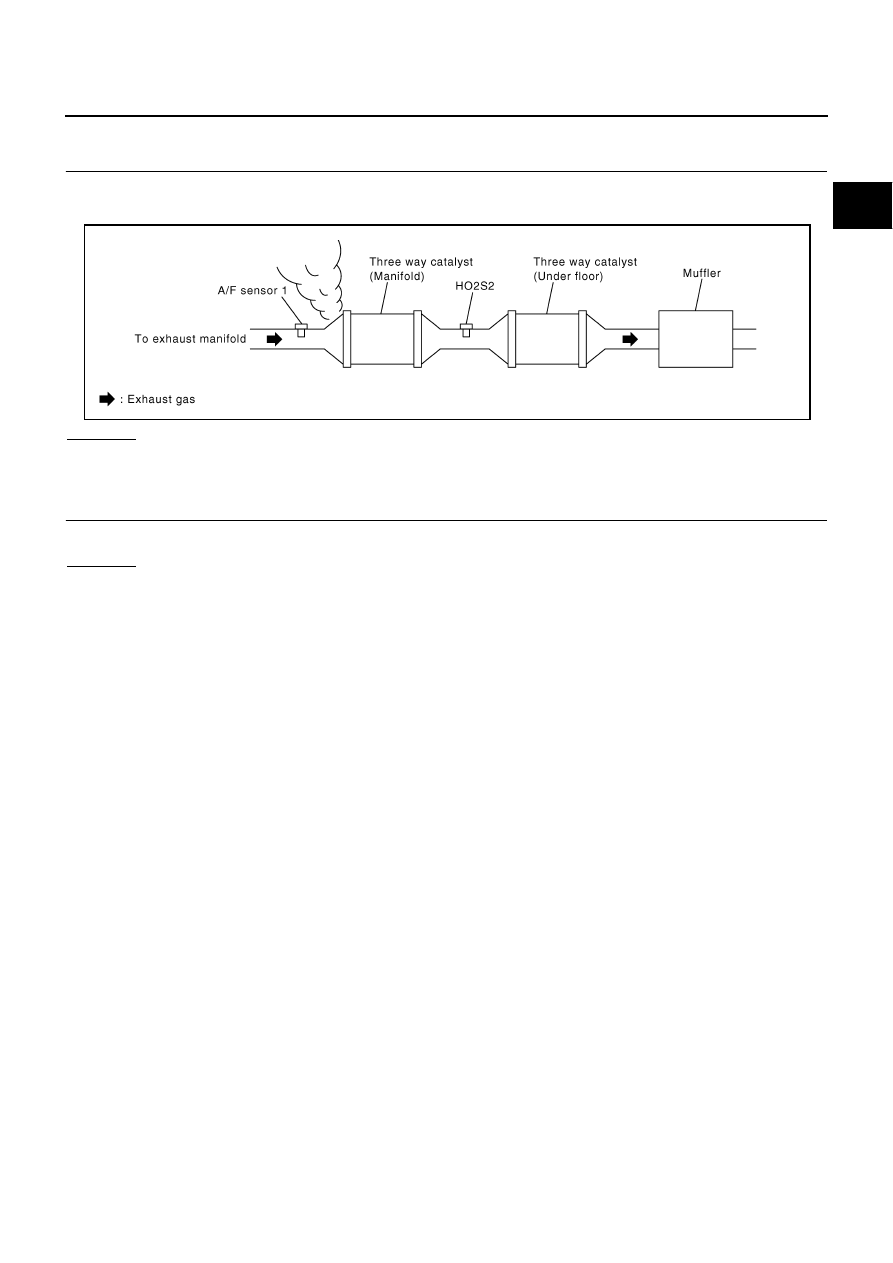

DTC P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-259

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2005 August

2005 Murano

Diagnostic Procedure

ABS00A5W

1.

CHECK EXHAUST GAS LEAK

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace.

2.

CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace.

PBIB1216E